E-Glass Fiber Assembled Roving for Chop 162

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 19320 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of E-Glass Fiber Assembled Roving for Chop

E-glass fiber chop roving is mainly designed as a reinforcement for GRP pipes. It is treated with a special silane-based siz and compatible with UP and vinyl ester resins. The product offers strong resin adsorbability and the end products have strong water resistance and excellent chemical resistance. The roving is typically used to make GRP pipes.

Specification of E-Glass Fiber Assembled Roving for Chop :

PRODUCT NAME | E-GLASS FIBER ASSEMBLED ROVING for SPRAY UP 2400TEX | |

TEST ITEM | STANDARD NO. | STANDARD VALUE |

LINEAR DENSITY(TEX) | ISO 1889-1997 | 2400±120 |

STIFFNESS (MM) | iso 3375-1997 | 135±15 |

COMBUSTIBLE MATTER CONTENT (%) | iso 1887-1995 | 1±0.15 |

moisture CONTENT (%) | iso 3344-1997 | ≤0.15 |

Product Properties of E-Glass Fiber Assembled Roving for Chop:

1. Excellent process: easily chopped, good dispersion flay lying down and good anti-static performance.

2. Good wet-out: quick wet-out (resin), easily delete bubbles, well compatible with different resins.

3. Good composite performance: the composite is with properties of high mechanical strength and high transmittance etc.

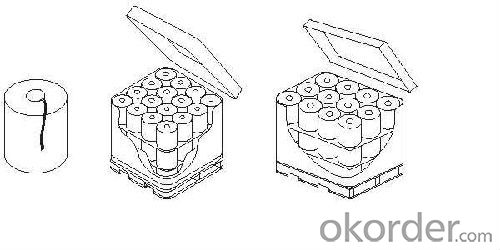

Package of E-Glass Fiber Assembled Roving for Chop:

The roving to be packed on 20 pallets for a 20' container. The detailed package is listed as follows,

4 X 4 rolls/layer, 4 layer/pallet, 10 pallets

4 X 4 rolls/layer, 3 layer/pallet, 10 pallets.

Each layer is seperated with paperboard.Each pallet is supported by very strong papercoil at the four corners of pallet, then packed in big carton, wrapped in a polythene stretched film. The roving on pallet after package is visible.

Storage of E-Glass Fiber Assembled Roving for Chop:

Unless otherwise specified, fiberglass products should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃-35℃ and 35%-65% respecitively. To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high. When the pallets are stacked in 2 or 3 layers, care should be taken to correctly and smoothly move the top pallet.

FAQ

1. Why Choose us?

CNBM is a stated owned company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

6. Main Characteristics?

Fast wet-out, good dispersion performance, high split ratio;

And the size and specification can be produced and design according to your demand.

7. What is the Production Lead Time?

20*20GP each day.

- Q: What are used to produce glass?fiber geogrids.

- Modified material is the product made by combining oil refining product and the glass fiber products in order to increase the toughness of its product.

- Q: Medium alkali glass fiber cloth

- It is mainly used for large and medium sized non-metal container, equipment, pipe and shell.

- Q: Does centrifugal glass wool is made from glass fiber

- No, the eliminated one in the upper floor does not appear in ten years.

- Q: An introduction to glass fiber geogrid

- It is net?structure material woven through a certain method. In order to protect the glass fiber and improve the overall performance, it is geotechnical base material with excellent performance formed by a special coating treatment process. Glass fiber alkali free twistless roving is the main material of glass fiber geogrid.

- Q: Definition of glass fiber reinforced plastic doors and windows

- The unsaturated resin is used as the subtrate material. it have many advantages such as sound insulation and so on. Glass?reinforced?plastics is also called glass fiber reinforced material with lightweight property. Glass?reinforced?plastics doors and windows use glass fiber twistless roving and fabric as reinforcement material. It is a new type of composite material developed abroad in early twentieth Century and can add other mineral filler.

- Q: what are the material used for GRC decorative lines

- Cement, sand, glass fiber. We should pay attention to anti-cracking in interior decoration.

1. Manufacturer Overview

| Location | Chongqing, China |

| Year Established | 1971 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | North America, Eastern Europe, Southeast Asia, Mid East, Eastern Asia |

| Company Certifications | ISO9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Chongqing |

| Export Percentage | 40%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English |

| b) Factory Information | |

| Factory Size: | Above 2000,000 square meters |

| No. of Production Lines | Above 4 |

| Contract Manufacturing | |

| Product Price Range | Average |

Send your message to us

E-Glass Fiber Assembled Roving for Chop 162

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 19320 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords