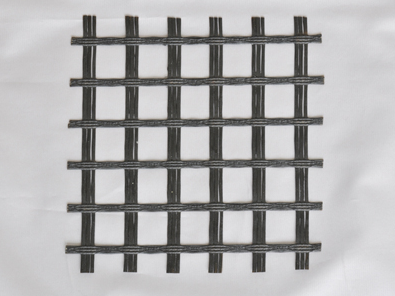

High Quality Basalt Geo-Grid with Roving Woven Fiberglass

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

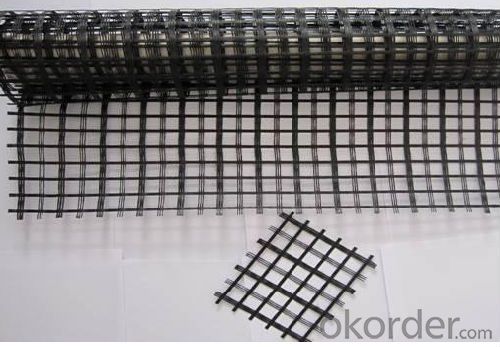

Fiberglass geogrid(Glass fiber grid) is plane network shape material that selects excellent reinforcement ype non-alkali glass fiber yarn, is weaved into base material by using foreign advanced warp knitter, uses warp knitting directional structure ,makes full use of yarn strength in textile, improves its chemical performance ,makes it has good tensio resistance, tearing resistance and creep resistance, and formed by excellentm modified asphalt (bitumen) mixture ,protects glass fiber base material fully and improves wearing resistance and shearing force resistance of base material so as to mak road surface reinforce ,to prevent highway harm such as crack and rut from occurring and to solve the problem that asphalt road surface is diffcult for reinforcement.

Specifications:

1.Fiberglass Geogrid size: EGA50/50 ---200/200

2.Price:USD 0.2 -- 1.0/Sq.m

3.Customize.

4.Found in 2003.

5.Exported 10 years

Features :

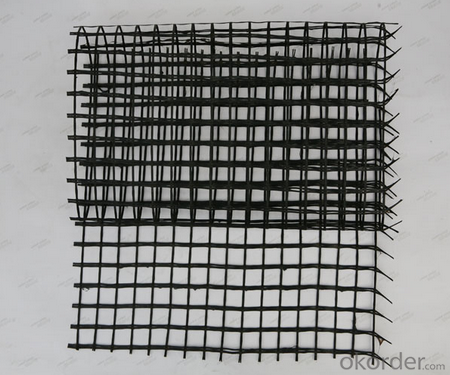

basalt fiber mesh fabric with high tensile strength, good compatibility with the mixture of asphalt can be very good against bio-erosion and climate change. As the asphalt mixture mixing temperatures up to 190 ℃ or more, the temperature of the basalt fiber mesh fabric mesh fabric in a variety of species present in a strong competitive advantage.

Standard: Standard, Traffic, "Highway Engineering basalt fiber and its products Part 3 of basalt fiber mesh cloth" Plan No.: JT2007-37, is currently approved by experts.

Ministry of Construction Standards "fiber reinforced composite grid" building standard (2008) 103 Man, currently being drafted.

Application:

laying cement concrete pavement, bridge pier reinforcing the dam and various building and construction joint surface of walls, pieces of cement mortar or concrete pouring.

FAQ:

1.What is the delivery time ?

We can promise you a short lead time ( 10-15days )

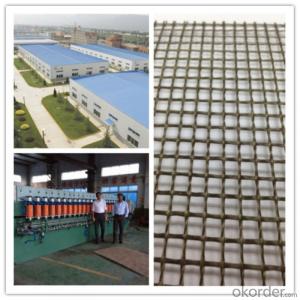

2.Are you a factory?

We have factory and can offer you direct price,and we have 10 yeas experiences

- Q: How to make a glass fiber reinforced plastic?

- The answer is no. The glass fiber reinforced plastic grille can be made with a mold, so it would be very easy to do it, while by manual, it would be troublesome, and do not have compressive property.

- Q: What is sheaf packing in waste plastic industry?

- Polymethyl methacrylate Acrylic is also known as Acrylic and it is a combination of chemicals such as acrylic acid and methacrylic acid. It is often said that acrylic plate is polymethyl methacrylate (PMMA) plate which is combined by methyl methacrylate monomer.

- Q: grc fiberglass

- If grc was shaped by injection, glass fiber chopped yarn will be fine; if it was shaped by hands, alkali resistant fiber glass with mesh of 1cm * 1cm will be fine.

- Q: Fiber has the difference between twist and twist

- Twist is the number of twists in the unit length of the yarn along the axis, generally expressed as a twist of /m

- Q: Where is atmospheric toxic liquid containers and how to operate it ?

- Color should be in accordance with the provisions in table 3 and it is not easy to fall off. Firstly, the surface of tube should be painted with soapy water or totally soaked in water. Rubber products should features with corrosion resistance and oil resistance. It should process liquid injection port sealing test.The technology file includes the following. Tank manhole and liquid injection port and strength layer can use resin with corrosion resistant as base material. When tank is out of factory, its surface hardness value should over 34. The defination of automotive paint coating. This standard uses the following definitions. It is in accordance with the JT with the minimum wall thickness is 5mm. Its head should adopt elliptic type head. The application of nitrogen should be adopted and it should be located at the right side of tank. The resin content should be controlled within 30% ~ 35% with the intake valve should be closed. A horizontal wavy plate should be installed. The test should be processed on a dedicated vent valve. Tank mark. A ring paint belt presenting transport liquid should be sprayed around the center line of the tank. Name of manufacturer. According to the method used in test 5, the outer surface should be smooth and oxygen content should between18% and 23% (volume ratio). Elliptical tank cross-section axial ratio is not greater than 2.12. The tank has vehicle safety requirements. The tank has not been thoroughly cleaned with its width is not less than 350mm. It is enduring dilute acid base rubber hose.

- Q: What is glass fiber extrusion

- Glass fiber extruding machine set can be used to produce different shapes of glass fiber reinforced plastics in different shapes, which can be formed by the oven traction machine oil pump station and so on.

- Q: how to produce glass?reinforced?plastics grating

- It is formed by glass fiber after extrusion.

- Q: Specific classification and application of glass fiber

- The excellent resin infiltration and permeability: Glass, in general, is hard and fragile. The warp and weft density is decided by yarn structure and texture. It is suitable for all kinds of spray gun and fiber conveying system. Due to its super strength, it can be used for producing packaging sheet and sports equipment. Twistless roving need to be soaked into resin paste with high content of pigment. The requirement that chopped?strand should be used to enhance thermoplastic?plastics is suitable for alkali free glass fiber.

Send your message to us

High Quality Basalt Geo-Grid with Roving Woven Fiberglass

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords