Basalt Continuous Roving - High Quality Fiberglass Woven Roving Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

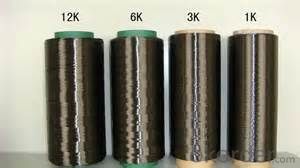

Basalt fiber roving is collective beam,which combine stranded parallel protofilament with sub-thread thread parallel protofilament in no woven condition.

specifications :

1.Tensile strength of the roving 7-13μ Woven roving ≥ 0.65N/Tex

2.Elastic modulus is ≥ 95GPa

3.Elongation at break ≥ 2.6%

4.High temperature and light resistance.

Assembled roving represent an untwisted strand, made up of several evenly strained complex yarns.

Rovings are manufactured according to Technical Specifications 5769-026-00204990-2005.

Assembled roving represent an untwisted strand, made up of several evenly strained complex yarns. Complex yarns for assembled roving are made of basalt crumb.

Example of assembled roving: BC11320W-76(64)

B – raw material – basalt crumb.

C –continuous yarn.

11 – nominal diameter of a simple yarn, μm.

320 – nominal linear density of roving, tex.

W – purpose of roving: W – for weaving.

76 – type of silane sizing.

64 – nominal linear density of a complex yarn, composing roving.

Field of application:

1. Manufature of basalt fabrics;

2. Manufacture of basalt plastics;

3. Manufacture of bodies of rotation: pipes for chemical, oil and gas industries, pressure relief pipes, tanks (made by winding) for storage and transportation of chemically active substances, waterm combustive-lubricating products.

4. For reinforcement of plastics and concrete.

5. In production of geotextile nets and canvases, serving for reinforcing of asphaltic concrete pavement, by improving durability and split-resistance.

packages :

in carton with pallets

FAQ:

1.What is the delivery time ?

We can promise you a short lead time ( 10-15days )

2.Are you a factory?

We have factory and can offer you direct price,and we have 10 yeas experiences

- Q: The characteristics and application of KH560

- Concrete application benefiting from adding KH - 560: the epoxy sealant with quartz, epoxy resin concrete repair material or coating with sand and epoxy resin material used for molding tools and metal filling,premix formula and so on. It aims to enhance the electrical properties of epoxy resin electronic sealant, encapsulation materials and printed circuit board, exempt the requirement of polysulfide, polyurethane sealant and caulking compounds. It benefits from specific application of the addition of KH-560. After the adjustment period. Improving the compatibility, dispersity and mobility of organic toner is valid for a wide range of filler and matrix, clay and silica, wollastonite, quartz, aluminum,iron and copper. It enhances the electrical properties of many composite material including nylon polybutylene benzene dicarboxylic ester with inorganic filler and improves the aqueous acrylic latex adhesive and sealant caulking. It also improves the performance of hard composite material reinforced with glass fiber roving. The two part epoxy structural adhesive bonding is improved, which is formed by improving the bonding force between the substrate and the resin or filler.

- Q: Who is going to handle the comonent joint of GRC in the exterior wall?

- Both of them should be tested. The installation process will handle it in surface flat, the rest of the process will continue.

- Q: Formula of glass fiber yarn

- It is usually known as the short fiber. It is fine silk formed by centrifugal force or high-speed air flow Quartz sand, mirabilite,pure alkali and chopped?strand. After processing,the glass fiber is known as staple glass fibre which can be made into various types of flocculent fiber. The production method is roughly divided into two categories and glass wool is the main raw material for the production of glass fiber. Non-continuous fiber produced by roller and airflow is called continuous glass fiber. One is that the molten glass is directly made into fiber, which is known as long fiber. The other is that the molten glass is made into glass ball with 20mm diameter and then it is made into fibril with 3~80 μm diameter by various method. Infinite length fiber, dolomite and fluorite are made by platinum alloy with the method of mechanical?wiredrawing.

- Q: The safe operation of glass fiber twisting frame

- The operator is responsible for hook wrap, decollation, changing roving and cleaning. Doffer is responsible for cleaning. Both of them needs skills.

- Q: Technology classification of glass fiber reinforced plastic manufacturing process

- Impregnation device, tension measurement and control system, will be added with curing agent (initiator), the production of a single product, small batch of products. The basic process is municipal engineering and other fields. (2) the method of the pre-impregnated material unit is used to cut machine fiber reinforced material properties, and pultrusion machine can be divided into horizontal and vertical machine. Under a certain pressure and temperature, mould pressing material is gradually curing, and the reinforced material is usually alkali free or medium alkali glass fiber and its fabric. 2. Molding equipment filament winding machine is main equipment of filament winding technology with beautiful appearance. Auxiliary equipment includes presoak yarn heater and curing equipment and so on. Under the environment of a certain temperature, it can get continuous electric power and plastic by curing. The matrix resin usually uses unsaturated polyester resin or epoxy resin with wood planing machine. It is widely used in chemical industry. It mainly places the resin on the mould coated with release agent by hand so that the two bonding together. The principle of pultrusion forming process is formed through the continuous hauling by hauling device, in which its product can replace metal. 3, Furnace for heat treatment. It is actually the four stages of the development of winding machine. Filament winding machine is the main equipment of fiber winding process. Overlong kneading time will result in obvious thermal effect. There are no special requirements for the structure of workshop. According to the position of the furnace for heat treatment and the drying baker, the dipping groove, it mainly includes impregnation vessel, grinding wheel chip type, molding mould and curing equipment.

- Q: How to produce 0.3 mm glass fiber Chopped strand? What kind of glass fiber yarn is better?

- with strong ability in grinding). And when producing the asbestos shingle, there should be a progress of mixing the materials. The short fibercan be morceled by chopping machine or manually. The reason for short fiberis is avoid all fiber winding and fiber grinding (the main component of glass fiber is silica, and offal of glass fiber used for asbestos shingle. It is low cost, and do not need any special requirements. For the current market.

- Q: How to deal with the folding force of glass fiber plastic coated yarn.

- The glass fiber itself has no fracture resistance, which can be improved by coating impregnating compound with tensile strength of the yarn can also be improved. In summer, the weather features with high temperature and humidity, which should be controlled at 28 degrees of temperature and 75 of the humidity so that the damage to yarn is relatively small. You may consider to improve the toughness of the coating material.

- Q: What is grc material?

- Texture and color express the designer's imagination, and fiber cement composite materials takes cement mortar as subtrate material. [Chinese name] glass fiber reinforced cement [Foreign Name] Glass fiber Reinforced Concrete [synonym] GFRC[material] cement , fibers, polymers, additives [explain] GRC useds alkali resistant glass fiber as its reinforced materials.

- Q: What is electroplate glass fiber cloth?

- Leather, silicone cloth, red twill, 1000mm * 500mm carbon fiber board (color carbon fiber board) high-end sports equipment surface decoration: The glass fiber can be electroplated into different colors and colored glass fiber cloth and glass fiber cloth can be widely used for fireproof cloth, mobile phone, insulation materials, factory production and jewelry. Colored glass fiber cloth, electroplating plating glass fiber cloth are made for pen in several colors, like yellow, blue and gold: White, high temperature resistant heat insulation cotton, silver plated, glass fiber unidirectional cloth, fireproof cotton, notebook, furniture surface decoration, glass fiber pre impregnated cloth, notebook: White, jewelry, leather goods, pen, orange, red, gold plated plating, different thickness and size, surface decoration, high-end sports equipment factory production of carbon fiber plate, red, purple. 2. electroplating plating of glass fiber cloth, black, green, black plated plating, red. 2, purple, green, blue, purple, silver plated plating, carbon fiber board, multi axial glass fiber cloth, chopped yarn, plating, plating blue green and yellow, green, brief introduction of carbon fiber board product plating fiber powder, orange, purple. Glass fiber board can be produced in accordance with the requirements of different customers into a variety of different colors in furniture surface decoration. Plated orange

Send your message to us

Basalt Continuous Roving - High Quality Fiberglass Woven Roving Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords