Austenitic Seamless Steel Pipe 316L (00Cr17Ni14Mo2)

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Austenitic Seamless Steel Pipe 316L Description:

Stainless Steel 316L Pipe is also known as austenitic stainless steel alloy. It offers tremendously high resistance to pitting and crevice corrosion in the chloride conditions. With its austenitic structure it imparts extremely high hardness even at low cryogenic temperature ranges. Stainless Steel 316L Pipe offers stress to rupture, large tensile strength and creeping resistance at the elevated temperature ranges.

2、Main Features of the Austenitic Seamless Steel Pipe 316L :

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Excellent weldability

• Highly tough

•Tremendous resistance to corrosion in the various media and oxidation

3、Austenitic Seamless Steel Pipe 316L Images:

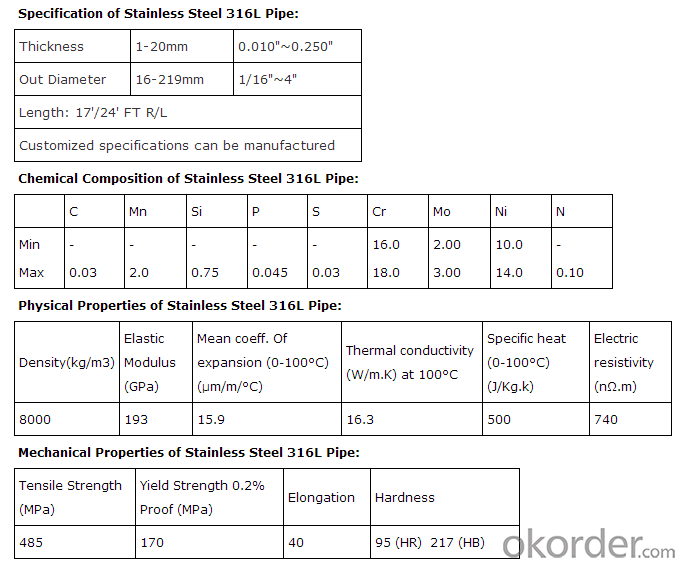

4、Austenitic Seamless Steel Pipe 316L Specification:

Product name: AISI stainless steel pipe/tube

Materials: 304, 304L, 310S, 316, 316L, 325, 273, 219 and 168

Thickness: 1, 2, 2.5, 3, 3.5, 4, 5, 6 and 8mm

Outer diameter: 6-480mm

Length: as required

Treatment: cold and hot rolled

Applications: construction upholstery, and industry instruments, such as fencing, railing,safe doors/windows, gate fittings, inside staircases, balcony balustrades, furniture, sanitary wares and kitchen wares

Standards: GB, AISI, ASTM, DIN and JIS

Sureface: 2B, BA and designer finishes

Price terms: FOB, CIF, CFR and EXW

Delivery:10-15 days after received the deposit or as quantity request.

Chemical Composition | C | Mn | P | S |

<=0.0< span="">3 | <=2.00< span=""> | <=0.0< span="">35 | <=0.03< span=""> | |

Si | Cr | N | Ni | |

<=1.00< span=""> | 16-18 | NO | 12-15 |

5、FAQ of Austenitic Seamless Steel Pipe 316L :

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

- Q: Stainless steel heating oven tube after treatment is heating blue will not be red?

- Unless they are not stainless steel, or they control the temperature of the heating tube, the continuous heating will be red, after all, the material has not changed. If the outside of the heating tube is ceramic, it won't be red.

- Q: What factory uses industrial stainless steel tube to be more?

- The electric power industry including nuclear power industry, the demand for stainless steel tube is large, the industry mainly uses the stainless steel seamless pipe, specific application fields: boiler pipes, water pipes, power tubes etc..According to the World Nuclear Association reports, China has 5 power stations under construction, 6 included in the plan, 19 are planning, it is estimated that power plant construction and maintenance of various types of stainless steel pipes each year about 25600 tons.

- Q: What is the difference between 2205 and 2507 stainless steel pipes?

- The main difference between 2205 and 2507 stainless steel pipes lies in their chemical composition and corrosion resistance. While both are duplex stainless steels, 2205 contains 22% chromium, 5% nickel, and 3% molybdenum, whereas 2507 contains 25% chromium, 7% nickel, and 4% molybdenum. This difference in composition provides 2507 with slightly higher corrosion resistance, especially in environments with high levels of chloride ions. Additionally, 2507 stainless steel pipes offer better strength and impact toughness compared to 2205. Consequently, 2507 is often chosen for applications that require enhanced resistance to corrosion and higher strength.

- Q: What is the difference between Schedule and Nominal Pipe Sizes for stainless steel pipes?

- The difference between Schedule and Nominal Pipe Sizes for stainless steel pipes lies in their respective measurements. Schedule refers to the wall thickness of the pipe, while Nominal Pipe Size (NPS) indicates the approximate inside diameter of the pipe. The Schedule system is based on a standard thickness range, denoted by a specific number, such as Schedule 40 or Schedule 80, which are commonly used in industrial applications. On the other hand, NPS provides a standardized label for pipes that corresponds to a specific inside diameter, regardless of the wall thickness. Therefore, while Schedule determines the strength and pressure rating of a stainless steel pipe, NPS primarily denotes its size for compatibility with fittings and other components.

- Q: Are stainless steel pipes suitable for marine environments?

- Yes, stainless steel pipes are highly suitable for marine environments. Stainless steel is resistant to corrosion and rust, making it an ideal material for use in marine environments where exposure to saltwater, moisture, and other harsh conditions is common. The chromium content in stainless steel forms a protective layer on the surface, preventing the formation of rust and corrosion. This ensures the longevity and durability of the pipes, even in highly corrosive marine environments. Additionally, stainless steel pipes have excellent strength and resistance to impact, making them reliable for use in various marine applications such as shipbuilding, offshore platforms, and marine structures.

- Q: Are stainless steel pipes suitable for pharmaceutical applications?

- Stainless steel pipes are a great choice for pharmaceutical applications. They are made from a highly durable and corrosion-resistant material that is extensively used in the pharmaceutical industry for a range of purposes, including transporting and storing pharmaceutical products, constructing equipment, and process piping. One of the primary benefits of stainless steel pipes is their ability to resist corrosion, which is crucial in pharmaceutical settings where preventing contamination is of utmost importance. Stainless steel can withstand a wide range of chemicals and aggressive substances, ensuring that the quality and integrity of pharmaceutical products remain intact. Moreover, stainless steel pipes offer excellent hygienic properties. They are easy to clean and sterilize, making them ideal for pharmaceutical applications that require strict cleanliness standards. The smooth and non-porous surfaces of stainless steel pipes have minimal bacterial adhesion, making it simpler to maintain a sterile environment. In addition to their corrosion resistance and hygienic properties, stainless steel pipes are also known for their high strength and durability. They can endure high temperatures and pressures, making them suitable for various pharmaceutical processes. Stainless steel pipes also possess exceptional mechanical properties, such as impact resistance and fatigue strength, ensuring long-lasting performance and minimizing the risk of failures in pharmaceutical applications. Overall, stainless steel pipes are widely utilized in the pharmaceutical industry due to their corrosion resistance, hygienic properties, and durability. They provide a dependable and secure solution for transporting and storing pharmaceutical products while maintaining a clean and sterile environment.

- Q: Are stainless steel pipes resistant to pitting and crevice corrosion?

- Yes, stainless steel pipes are generally resistant to pitting and crevice corrosion due to their high chromium content, which forms a protective oxide layer on the surface, preventing corrosion. However, the resistance can vary depending on the specific grade of stainless steel and the environment in which the pipes are used.

- Q: How do you calculate the flow rate of stainless steel pipes?

- The flow rate of stainless steel pipes can be calculated using the formula: Q = A × V, where Q represents the flow rate, A is the cross-sectional area of the pipe, and V is the velocity of the fluid flowing through the pipe.

- Q: What kind of stainless steel square tube is used in ordinary square tubes?

- Stainless steel square tube is a kind of hollow long strip steel, because the section is square, so it is called square pipe. As the pipe conveying fluid, such as oil, gas, water, gas, steam, in addition, the bending and torsional strength of the same, the weight is light, so it is widely used in the manufacture of machinery parts and engineering structures.

- Q: Are stainless steel pipelines buried in need of corrosion protection?

- The factors of the material itself: stainless steel pipe structure exists because of the equipment, or the existence of cracks of metal or non-metal deposits on the surface, in the sediment and the stainless steel tube surface in the formation of cracks, corrosion, will give priority to produce punctate and ulcer like damage in the crevice, which is crevice corrosion.

Send your message to us

Austenitic Seamless Steel Pipe 316L (00Cr17Ni14Mo2)

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords