Austenitic Seamless Steel Pipe 316L 00Cr17Ni14Mo2

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1、Structure of Austenitic Seamless Steel Pipe 316L Description:

Stainless Steel 316L Pipe is also known as austenitic stainless steel alloy. It offers tremendously high resistance to pitting and crevice corrosion in the chloride conditions. With its austenitic structure it imparts extremely high hardness even at low cryogenic temperature ranges. Stainless Steel 316L Pipe offers stress to rupture, large tensile strength and creeping resistance at the elevated temperature ranges.

2、Main Features of the Austenitic Seamless Steel Pipe 316L :

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Excellent weldability

• Highly tough

•Tremendous resistance to corrosion in the various media and oxidation

3、Austenitic Seamless Steel Pipe 316L Images:

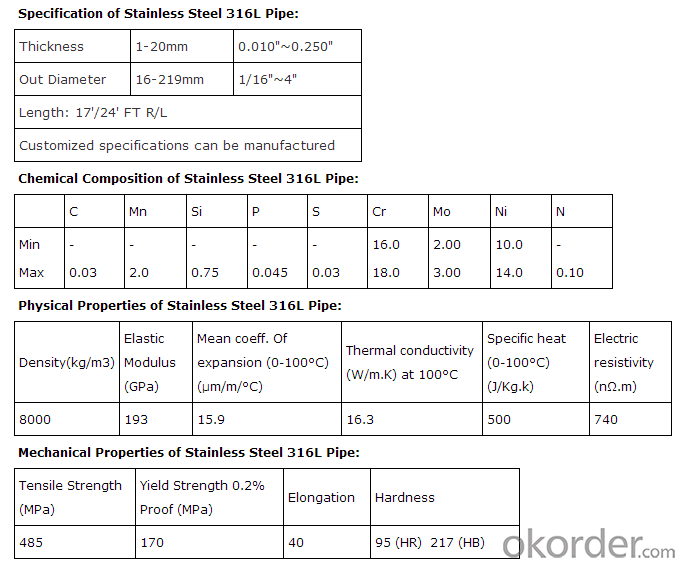

4、Austenitic Seamless Steel Pipe 316L Specification:

Product name: AISI stainless steel pipe/tube

Materials: 304, 304L, 310S, 316, 316L, 325, 273, 219 and 168

Thickness: 1, 2, 2.5, 3, 3.5, 4, 5, 6 and 8mm

Outer diameter: 6-480mm

Length: as required

Treatment: cold and hot rolled

Applications: construction upholstery, and industry instruments, such as fencing, railing,safe doors/windows, gate fittings, inside staircases, balcony balustrades, furniture, sanitary wares and kitchen wares

Standards: GB, AISI, ASTM, DIN and JIS

Sureface: 2B, BA and designer finishes

Price terms: FOB, CIF, CFR and EXW

Delivery:10-15 days after received the deposit or as quantity request.

Chemical Composition | C | Mn | P | S |

<=0.0< span="">3 | <=2.00< span=""> | <=0.0< span="">35 | <=0.03< span=""> | |

Si | Cr | N | Ni | |

<=1.00< span=""> | 16-18 | NO | 12-15 |

5、FAQ of Austenitic Seamless Steel Pipe 316L :

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

- Q: What are the different methods of repairing damaged steel pipes?

- There are several methods for repairing damaged steel pipes, including welding, epoxy coatings, pipe wrapping, and pipe lining. Welding involves fusing the damaged sections of the pipe using heat and specialized equipment. Epoxy coatings are applied to the damaged area to create a protective layer and restore the pipe's integrity. Pipe wrapping involves applying specialized tapes or wraps around the damaged area to provide structural support. Pipe lining involves inserting a new pipe into the damaged one, creating a seamless and durable solution. The appropriate method depends on the extent and location of the damage, as well as other factors such as cost and time constraints.

- Q: What are the different methods of pipe insulation for steel pipes?

- There are several methods of pipe insulation for steel pipes, each with its own advantages and suitability for specific applications. Some of the commonly used methods include: 1. Fiberglass insulation: This is one of the most popular methods of pipe insulation. Fiberglass insulation is made of fine glass fibers and is available in various forms such as rolls, sheets, or pre-formed sections. It is lightweight, easy to install, and provides excellent thermal insulation properties. 2. Foam insulation: Foam insulation is another effective method for insulating steel pipes. It is available in different forms, including rigid foam boards or spray foam. Foam insulation is known for its high insulating value and its ability to seal gaps and cracks, providing enhanced energy efficiency. 3. Rubber insulation: Rubber insulation, commonly known as elastomeric insulation, is widely used for insulating steel pipes in HVAC systems. It is flexible, durable, and resistant to moisture, making it suitable for both indoor and outdoor applications. Rubber insulation also offers good thermal and acoustic insulation properties. 4. Polyethylene insulation: Polyethylene insulation is a cost-effective option for insulating steel pipes. It is available in different forms, such as foam tubes or molded sections, and is easy to install. Polyethylene insulation provides good thermal insulation, protects against condensation, and is resistant to water vapor diffusion. 5. Cellular glass insulation: Cellular glass insulation is a rigid insulation material made from crushed glass and a foaming agent. It is known for its exceptional thermal insulation properties, as well as its resistance to moisture, fire, and chemicals. Cellular glass insulation is commonly used in cryogenic and high-temperature applications. It is important to consider factors such as temperature, moisture conditions, and the specific requirements of the project when selecting the appropriate method of pipe insulation for steel pipes. Consulting with a professional or an insulation expert can help determine the best insulation method based on the specific needs and conditions of the project.

- Q: What are the advantages of using steel pipes in industrial plants?

- There are several advantages of using steel pipes in industrial plants. Firstly, steel pipes are incredibly strong and durable, capable of withstanding high pressures and extreme temperatures, making them suitable for transporting various liquids and gases. Secondly, steel pipes have excellent resistance to corrosion, ensuring a longer lifespan and reduced maintenance costs. Additionally, steel pipes have a smooth interior surface, minimizing frictional resistance and allowing for efficient flow of materials. Lastly, steel pipes are highly versatile, with different sizes and thicknesses available, making them suitable for a wide range of applications in industrial plants.

- Q: What is the creep resistance of steel pipes?

- The creep resistance of steel pipes refers to their ability to withstand deformation or elongation over time when subjected to high temperatures and constant stress. Steel pipes are known for their excellent creep resistance due to the inherent strength and stability of the material. The specific creep resistance of steel pipes can vary depending on factors such as the alloy composition, heat treatment, and the operating conditions they are exposed to. Creep is a phenomenon that occurs at elevated temperatures where materials slowly deform under constant stress. In the case of steel pipes, this can be a concern in applications where they are exposed to high temperatures for prolonged periods, such as in power plants, industrial furnaces, or steam pipelines. The resistance to creep deformation is crucial to ensure the structural integrity and longevity of the pipes. Steel pipes are often designed and manufactured with alloys that have high creep resistance properties, such as chromium-molybdenum (Cr-Mo) steels or nickel-based alloys. These alloys exhibit excellent mechanical strength, good thermal stability, and resistance to oxidation and corrosion, all of which contribute to their superior creep resistance. Furthermore, heat treatment processes like quenching and tempering can significantly enhance the creep resistance of steel pipes. These treatments involve controlled heating and cooling cycles that optimize the microstructure of the steel, increasing its resistance to deformation and improving its overall performance at high temperatures. It is important to note that the creep resistance of steel pipes is typically specified by industry standards and codes, such as the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code. These standards define the allowable stress levels and design criteria for various steel pipe applications, ensuring that they meet the required safety and performance standards. In summary, steel pipes are known for their excellent creep resistance due to their inherent strength, stability, and resistance to high temperatures. The specific creep resistance of steel pipes can vary depending on factors such as alloy composition, heat treatment, and operating conditions. Proper design and adherence to industry standards are crucial to ensuring the desired creep resistance and overall performance of steel pipes in various applications.

- Q: Can steel pipes be used for food processing facilities?

- Yes, steel pipes can be used for food processing facilities. Steel pipes are commonly used in the food industry due to their durability, resistance to corrosion, and ease of cleaning. They are also suitable for various processes such as conveying liquids, gases, and solids, making them a reliable choice for food processing facilities.

- Q: How are steel pipes used in the aerospace manufacturing industry?

- Steel pipes are commonly used in the aerospace manufacturing industry for various applications. They are primarily used for the construction of aircraft structures, such as fuselages, wings, and landing gear. Steel pipes offer excellent strength and durability, making them suitable for withstanding the extreme conditions experienced during flight. Additionally, they are used in the aerospace industry to transport fluids, such as fuel and hydraulic systems, due to their ability to handle high pressure and temperature. Overall, steel pipes play a critical role in ensuring the safety, reliability, and performance of aircraft in the aerospace manufacturing industry.

- Q: The difference between carbon and welded steel tubes

- Seamless steel pipe is made of Steel No. 10-20. It is of high quality carbon structural steelWelded steel pipe is usually welded by Q235 steel plate

- Q: How are steel pipes used in the construction of water supply systems?

- Steel pipes are commonly used in the construction of water supply systems due to their durability, strength, and resistance to corrosion. They are used for transporting water from sources such as reservoirs and wells to treatment plants, and then distributing it to homes, buildings, and other structures. Steel pipes are also used for transporting wastewater and sewage. Their ability to withstand high pressure and extreme weather conditions makes them ideal for ensuring a reliable and long-lasting water supply infrastructure.

- Q: How are steel pipes used in the manufacturing of food processing equipment?

- Steel pipes are commonly used in the manufacturing of food processing equipment due to their durability, corrosion resistance, and ability to handle high temperatures. They are used to transport liquids, gases, and food products within the equipment, ensuring hygienic and efficient operation. Additionally, steel pipes can be easily cleaned and sanitized, making them ideal for maintaining food safety standards in the manufacturing process.

- Q: What is lined pipe?

- Pipe lining is a new technology in recent ten years of development, also called composite pipe conveying fluid with different needs, the use of different materials to make the durability of the pipeline inner wall and outer wall of pipeline, to ensure the purity of the fluid, pipeline adaptability, performance is greatly improved, more extensive use.

Send your message to us

Austenitic Seamless Steel Pipe 316L 00Cr17Ni14Mo2

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords