AR Glassfiber Chopped Strand for GRC

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 18MTS watt

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of AR Glassfiber Chopped Strand for GRC:

1.AR Fiberglass Chopped Strands For GRC, GRG

2. Alkali-resisting

3. With zirconium dioxide

4. Good packing

Item | length(mm) | packing(mm) | net weight/bag(kg) | linear density (tex) | ZrO2% |

AR15-98 | 6,8,12,16 | 550×550×65 | 15 | 98 | 14.5, 16.5 |

The Working Application of AR Glassfiber Chopped Strand for GRC:

1> Reinforced material of internal and external insulation systern of wall,

2> Internal and external insulation panel, flat board, wavy tile, division panel, moving house.

3> Outer decoration component parts of European style, imitate ancient building, artistic sculpture, garden feature,

4> Decorative panel, duct panel, cable box, granary, water tank, bathtub,

5> Channels drainage and irrigation, hardening dykes and dam of river,

6> Corrosion-proof chemical pipe, storage tank, military project.

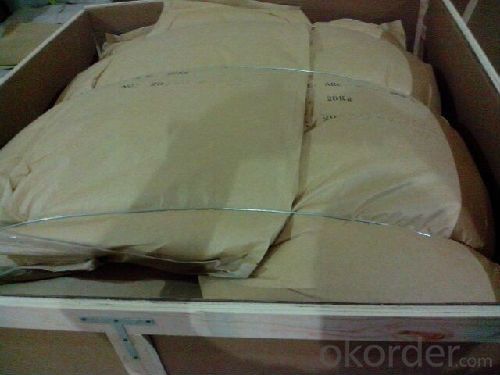

Packaging of AR Glassfiber Chopped Strand for GRC

--10kg per plastic bag, two plastic bag(20kgs) per paper bag,

--39 paper bags per pallet, net weight 780kg,

--20 pallets in a 20 feet container, net weight about 15.6 tons.

- Q: x barrels of this concrete, the number of barrells of cement used isA) x/5B) x/4C) xD) 4xE) 1/5xPlease explain.

- B 1 part cement to 4 parts sand. If you made 10 barrels of concrete you would have 10 parts cement and 40 parts sand.

- Q: Is there any way to remove rubber cement stains? From clothes and carpet?

- Rubber cement may be a great tool as an adhesive, but when that adhesive turns into a stained mess on your fancy tablecloth or carpet it's not that great anymore. Removing unwanted rubber cement stains takes time and patience along with a few simple tools.

- Q: Please help me out here

- 7 tons of cement 11.67 tons of gravel 16.33 tons of sand. Say X is the amount of cement (don't worry about the 3). How much gravel is there in relation to cement? 5/3 as much.For every 3 of cement, there's 5 of gravel. How about the sand? There's 7/3 as much sand as there is cement.So now you can restate the whole thing with respect to cement: However much cement + 5/3 more gravel than cement + 7/3 more sand than cement = 35 tons. X + (5/3)X + (7/3)X = 35. X ends up equaling 7, (5/3)X is 11.67, and (7/3)X is 16.33. Hope this helps!

- Q: My cat has urinated on the cement basement floor around the area of the litter box. It is my fault for not cleaning the litter box right away, but now I have a problem! I have tried dousing the area with vinegar and letting it air dry. Any other suggestions?

- Bleach your cement floors First, wash the soiled area with any appropriate cleaner you have that DOES NOT contain ammonia. Once clean, wipe the area down with fresh water to remove any residue left behind by the cleaner. Next, do it again. After your second washing and wiping, employ your bleach. In a clean spray bottle, mix a 10:1 water to bleach solution. Make sure the area you are cleaning in is well ventilated, put on some rubber gloves and get to work. Spray on lightly, let sit for about 30 seconds, and wipe off with a clean damp rag.

- Q: The house was built in 1925 without foundation tile, over the years whatever was painted over the brick interior walls has bubbled because of the moisture that would have been diverted by an appropriate ditch around the foundation, or tiles to drain it, etc. Several of these bubbles are basketball in size, and there are cracks in many areas of the stucco-like stuff that chips off in large pieces. I want to patch it up, and repaint, what is that stuff called? It looks like cement when chipped off, is it joint compound? How should I go about this? Moisture problems have been aleviated, now I just need to fix the cosmetics.

- When you've got any moisture you desire a moisture sealer. If not that's even higher, makes it lot easier. Prime with zinnser primer tinted virtually the color of your paint. Then comply with with a LATEX PAINT making use of a thick nap curler. If you wish to make it ornamental, buy a sponge curler and use a second colour and position over most effective the skin of the block. It appears rather first-class and dresses it up alot. Good success!! You should utilize a latex paint. I painted block wall in basement that was once getting some moisture, and did use zinnser primer adopted with the aid of latex about 10 years ago and it looks as good in these days as the day I painted it!! So i do know for fact it can be performed.

- Q: I am just curious, if I were to use 6 inches of reinforced concrete, making a 'domed tunnel' 100 feet long, how much weight would it be able to support on top? I know a dome can take a lot of weight, but what would be the math formula for figuring this out?Reinforcement would be 5/8quot; steel re-bar creating a skeletal structure to inject cement into and around.

- Portland cement reinforced will have a maximum sustained tensile strength of 2500 PSI. Monolithic dome construction utilizes Gunite which is the same material used for swimming pools, and can withstand 5000 PSI or greater as it must support water's weight of approx. 8 lbs per gallon.

- Q: who can tell me a world cement website?

- If okorder they are the biggest cement manufacture in the would,you can search for information there.

- Q: What is the use of using oxygen in cement industry?

- The ingrediants for the cement need to be heated to a very high temperature to make Portland cement. Usually methane with air is the heat source, but oxygen replacing some of the air is sometimes needed to reach the optimum temperature. Possibly a superior cement is produced if it has negligible nitrogen, argon and carbon dioxide, so oxygen is used instead of air which contains nitrogen, argon and carbon dioxide as well as oxygen.

- Q: hi i know how cement is made. my main question is when do we use cement entirely? for instance, concrete is used to make roads etc. similarly, in constructing a 10 floor building, do we concrete in all the 10 floors or is concrete used only in foundation and pilings/pillars etc? is cement used only as a smoothing agent or as binding agent in making brick walls etc.thx

- you use concreted to cover a person in.. You use cement to make shoes for a person out of tide boxes then you throw them in the water...

- Q: We're casting cement for testing, and we're not sure about how to calculate for the quantities. We're using a 15.24 cm diameter and 30.48 cm tall mould. We're using a water-cement ratio of 1:2, and a cement-sand-gravel ratio of 1:3:3. We're not sure how to calculate how much of everything we need, and we need the specific quantities for our methodology. Can anyone help?

- Total volume of the mould is pi r^2 h = 3.14159 (30.48) (15.24)^2 cm^3 = 22240 cm^3 The usual practice is to dry-blend the solids before adding the water, but I'm going to assume you really mean that the water amount is 1/2 the cement amount (not 1/2 the amount of total solids). You really need only enough water to make the mixture workable, but if 1/2 the cement is the correct amount of water, then the needed quantities are water 22240/15 = 1483 cc = 1.483 liters cement 44480/15 = 2965 cc (dry) sand 44480/5 = 8896 cc gravel 44480/5 = 8896 cc total = 22240 cc Probably best to mix up a bit extra of all the dry stuff in case the amt of water needed turns out to be less than you think.

1. Manufacturer Overview

| Location | Hubei,China |

| Year Established | 2005 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | Southern Europe 10% Northern Europe 10% Central America 10% Western Europe 10% Eastern Asia 10% Mid East 30% Africa 20% |

| Company Certifications | N/A |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai PORT |

| Export Percentage | |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | |

| Product Price Range | 示范:High;Average |

Send your message to us

AR Glassfiber Chopped Strand for GRC

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 18MTS watt

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords