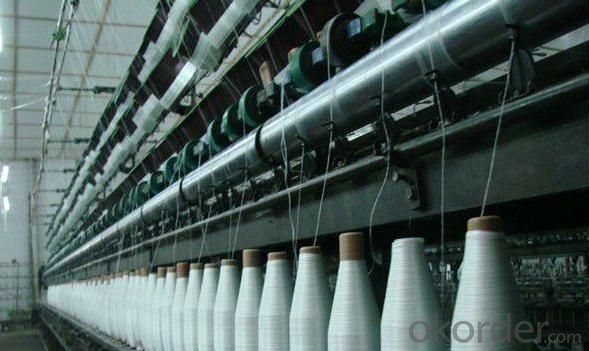

AR Glass Fiber Chopped Strand for Concrete Chopped Strand

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of AR Glass Fiber Chopped Strand for Concrete:

1. Modest water content

2. Good flowability

3. Even distribution

Instruction of AR Glass Fiber Chopped Strand for Concrete:

AR Glass Fiber Chopped Strand for Concrete is a high integrity AR glassfibre chopped strand designed for use in dry mix systems or other premixing processes for subsequent moulding into a GRC component.

This kind of chopped strand has a sizing system optimised for abrasion resistance and strand integrity during blending with dry materials .The low-tex strand permits efficient reinforcement at low dosages .It is particularly suited to the preparation of pre-bagged mixes of special mortars or renders .It may also be used in the manufacture by precasting of standard GRC components.

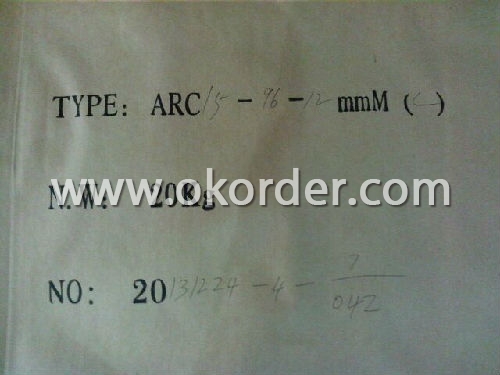

Technical Characteristics of AR Glass Fiber Chopped Strand for Concrete:

Tex of strand(tex) | Sizing content(%) | Moisture(%) |

JC/T572-2002 | JC/T572-2002 | JC/T572-2002 |

98±10 | 1.6±0.2 | ≤0.2 |

Package of AR Glass Fiber Chopped Strand for Concrete:

20KG/Paper bag and then put into the Pallet

- Q: My Albanian friend said he is going to get me a pair of quot;cement shoesquot; for my birthday.What do you think he meant by that? Is that some sort of Albanian lingo?

- that actually comes from an old Italian mafia jargon. Allegedly, when they killed somebody and wanted to make the body disappear, they would dip the feet of the corpse in cement, which then solidified to make cement shoes or overshoes. Then, when the body was dumped in the water (lake, river, sea), the weight of the cement shoes would prevent the body from floating to the surface...

- Q: So am trying to remodel my bathroom and was wondering if cement board would work better than greenboard as the shower wall? I've read that cement board can be used on floors or kitchen tops but am not sure if I can use it on bathrooms??

- Cement board all the way over wall to put tile onto. I ve repaired, tore down and made good money fixing tile that was placed over green board. On a well used shower or tub area the life of green board before it starts to wick in the water and rot is 5/7 years. Not worth the minimal savings to put in green board. The one main key people don t do is to put up a simple vapor barrier behind the cement board and this should be done with green board to. No questions its cement board on walls, floors etc. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: I am a competitive tennis player and I would like to build a cement wall (like those ones at parks and such) that I can hit against in my backyard. Is that legal and how much would it cost?

- firstly to build a wall is classed as a non-tempory construction so you will probably have to ask your town mayer or local council if you can put one up first. and for a brick wall covered in cement would cost around ?35 per square metre. If you do decide to put one up try shaving one side of the tennis ball and then play around with that i have done this in the past when playing against my house wall and the idea behind it is so that it puts a spin on the ball and makes it change direction more so that you don't know where its going to come from which i think makes it a bit more fun and challenging.

- Q: im 14 and im going to buy some weights for boxing,football,baseball basically for sports they have $60 100 pound golds gym cement filled weights im a beginner so do you think I should buy them because iron is too expensive and too young for gym

- you are not to young for a gym most gyms just require you to sign up with one person over 18 then you can go freely by yourself.

- Q: There's this movie I saw a while ago but I forgot the title. I don't remember what it is about either except that it is something about a crazy man and a haunted place I think or something like that and people are locked in dark underground basements and buried in wet cementI remember how the movie starts though: A little girl who was locked in an underground room and then there was wet cement being poured into the room. She screamed and then died.And then I think the rest of the movie was that happening to other people.Any help?

- I watched this a few nights ago on On Demand (for free) and plan to watch it several more times if possible. The movie does open with a little girl sealed inside walls, then cement begins pouring in. The scene cuts away just as only her face is out of the muck~a very chilling moment!

- Q: What are the types of portland cement?

- their aren't any types, cement is cement. what your going to use it for determines what additives you mix in with it.

- Q: quot;What date was cement made?

- 1.Cement is made by heating powdered limestone and clay. 2.It is used in mortar and concrete - mortar is used to join bricks together and is made by mixing cement with sand and water - concrete is made by mixing cement with sand, water and aggregate (crushed rock) 3.it sets and hardens quickly so building is faster. 4. Portland cement mortar was invented in 1794 and patented in 1824. It gained in popularity over lime mortar by the latter part of the 19th century and by 1930 has all but replaced lime mortar for new construction. Lime mortar was first used in Mesopotamia and was made by heating up limestone to drive out the water, then grinding it to a powder, which had sand added to it for greater strength. To use it, water was mixed to it to form a paste which slowly hardens. It was used in the Pyramids.

- Q: The chimney is deteriorating due to water getting in the cement block.

- fix the concrete and use a construction adhesive like pl 400 or liquid nails

- Q: I want to open building materials store main cement: tiles and the like. How much money to invest in the root. Store area of more than 100 square feet

- Oh! Open building materials shop ah! Professional guidance with you. Taobao check days Yao ceramic tiles glue, customer service will guide you

- Q: Where I live, winter doesn't have much snow. There is a small ski place with a snowmaker in the city that's about a 15 minute walk from my house. I've been walking there for the last few days and was worried that me walking on the sidewalk for 15 minutes a day with mith my board boots on could damage them. Can it?

- Yes... It will slowly wear them down and curve the edges... It will smooth the bottom of them and that can be dangerous if you are going to use them because they can slip out of the strap

1. Manufacturer Overview

| Location | Beijing, China |

| Year Established | 1991 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin Port |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

AR Glass Fiber Chopped Strand for Concrete Chopped Strand

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords