API Standard Oil and Gas Well Casing Tube K55

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

casing pipe for oilfield

API 5CT Q125 Casing Pipe|Olifield Casing Pipe

roduct: API 5CT oil casing pipe

Grade: Q125-1,Q125-2,Q125-3,Q125-4.

H40.J55.K55.N80.C75.L80.C90.T95.P110.

OD: 114.3mm to 508mm

Wall thickness: 5.12mm to 16.13mm

Length: R1(4.86-7.62M). R2(7.62-10.36M). R3(10.36-13Meters)

Thread: STC.BTC.LTC

Standard: API 5CT

Technical: Hot Rolled

Type: Seamless alloy API pipe

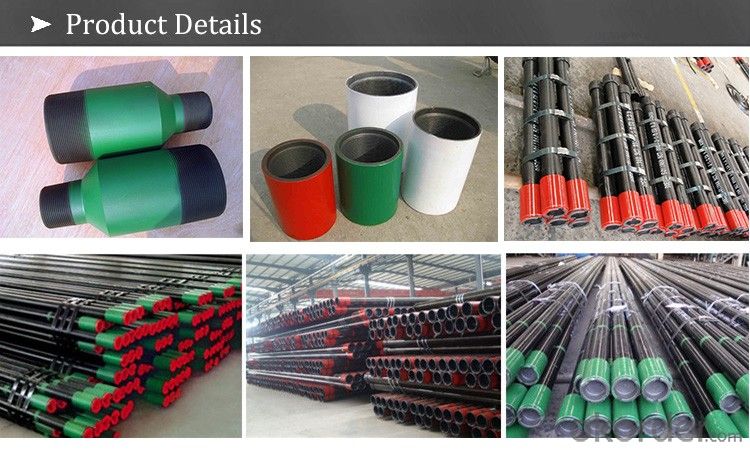

Surface treatment: blank oil painting+green/red/white/brown painting

Packing: Coating and steel thread protector,3tons in a bundle packed by steel strip

Third party inspection: BV|SGS|TUV

Usage: oil pipeline, oil natural gas, industrial gas, water transportation

Certificate:

API 5CT,Russian Certificate,ISO,CCS

Inspection

Physical properties are checked and each length hydrostatically tested, normally to only 3,000 psi in the plain end (unthreaded) condition. The following are also checked:

Dimensions

Weights

Straightness

Lengths

Part of this inspection is to drift all lengths.

Despite all the American Petroleum Institute (API) specifications and testing, some tubing defects are still found after delivery; thus, some operators do further inspection.

Inspection Method

Size and surface inspection

NDT and pressure test and third party certication

Hydrostatic

Drifting test

Physical and chemicail analysis

Hardness and pressure test.

Electromagnetic

Magnetic particle

Ultrasonic

Out Diameter weight Grade Thread Length in mm kg/m lb/ft 4-1/2" 114.3 14.14-22.47 9.5-15.10 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 5" 127 17.11-35.86 11.5-24.10 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 5-1/2" 139.7 20.83-61.14 14-22.22 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 6 5/8" 168.28 29.76-47.62 20-32 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 7" 177.8 25.3-84.97 17.00-57.10 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 7-5/8" 193.68 35.72-82.3 24.00-55.30 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 8-5/8" 219.08 35.72-72.92 24.00-49.00 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 9-5/8" 244.48 48-112.50 32.30-75.62 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 10-3/4" 273.05 48-127 32.75-85.30 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 11-3/4" 298.45 62.50-105 42.00-71.00 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 13-3/4" 339.72 71.43-107.15 48.00-72.00 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 16" 406.40 96.73-162.21 65.00-109.0 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 18-5/8" 473.08 130.21 87.50 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 20" 508.00 139.89-197.9 94.00-133.00 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 Remarks: 1 R1: 4.86M-7.62M R2: 7.62M-1036M R3:10.36M-12M 2 Standard: API 5CT 3 Grade: H40/J55/K55/N80/C75/L80/C90/T95/P110/Q125 Our service:

1): Durable, strict quality management and control, production follow the ISO.

2): Advanced precision casing pipe equipment to guarantee prime quality.

3): Casing pipe with smooth surface. No defects. Continuous skill improvements.

4): Short delivery, competitive good offer. Casing pipe MOQ is low.

5): Third party Inspection for casing pipe can be TUV/SGS/BV6): Company design team always think how develop new skill and new products to meet requirements of markets.

7): Good service, IF customers have any problem during application, we will surely try our best to solve them.

8): Regular thread is STC/LTC/BTC or as client's requirement.9): Surface treatment can be painted, or based on the requirements of customers.

- Q: How are steel pipes used in tunnel construction?

- Steel pipes are commonly used in tunnel construction for various purposes. They are used to provide structural support by acting as reinforcements or casings for the tunnel walls. Steel pipes also serve as conduits for utilities such as water, gas, and electricity within the tunnel. Additionally, they can be used for ventilation and drainage systems, ensuring a safe and functional environment inside the tunnel. Overall, steel pipes play a crucial role in the construction and functionality of tunnels.

- Q: Can steel pipes be used in the oil and gas industry?

- Yes, steel pipes are commonly used in the oil and gas industry. Steel pipes are known for their strength, durability, and resistance to corrosion, making them suitable for transporting and storing various fluids and gases in the industry. These pipes can withstand high pressure and extreme temperatures, which are often encountered in oil and gas operations. Additionally, steel pipes can be easily welded together, allowing for efficient assembly and maintenance. Overall, steel pipes are a reliable and cost-effective choice for the oil and gas industry.

- Q: What are the different types of joints used with steel pipes?

- Steel pipes commonly use several types of joints, depending on the specific application and requirements. Some of the most frequently used types are as follows: 1. Butt Joint: This type of joint is the most basic, involving the alignment and welding of two pipes at their ends. It creates a strong and continuous connection, but reinforcement may be necessary depending on the pipe's size and pressure rating. 2. Socket Weld Joint: Smaller diameter pipes often utilize this joint, where one pipe is inserted into the socket of another and then welded together. It provides good strength and resistance against leaks. 3. Threaded Joint: A threaded joint involves screwing together two pipes with threaded ends. It is commonly used in low-pressure applications and necessitates the use of pipe threads and sealants for a tight and leak-free connection. 4. Flanged Joint: In high-pressure applications, a flanged joint connects two pipes by bolting together flanges at their ends. This type of joint allows for easy disconnection and maintenance. 5. Grooved Joint: A grooved coupling is placed around the ends of two pipes in a grooved joint, which is then secured with bolts. This joint is commonly used in fire protection systems due to its quick installation and easy maintenance. 6. Welded Joint: A welded joint involves fusing two pipes together using various welding techniques like GTAW or GMAW. It provides a strong and permanent connection but requires skilled labor and additional equipment. Each type of joint has its own advantages and limitations, and the selection depends on factors such as pipe size, pressure rating, application, and installation requirements. Choosing the appropriate joint is crucial to ensure the integrity and reliability of the steel pipe system.

- Q: What are the lengths of scaffold steel tubes?

- Scaffold tubes are our name for materials used to build scaffolding, because most scaffolding uses tubular bamboo or steel tubing. Bamboo and other bamboo is for a long time in the use of the scaffolding tube, but due to lack of safety and durability, now only in rural and urban area construction is lagging behind some of the home building small building has been used. The modernization construction, the most commonly used type of scaffolding pipe is steel pipe, the scaffolding should not only meet the demand of workers, but also to meet the characteristics of scaffolding firm and durable, so tough hard steel is the best choice. The selected steel pipe generally requires smooth surface, no cracks, no bending, no rust, and meet the relevant national standards.

- Q: Can steel pipes be used for shipbuilding?

- Yes, steel pipes can be used for shipbuilding. Steel pipes are commonly used in shipbuilding due to their high strength, durability, and resistance to corrosion. They are utilized for various purposes such as structural components, piping systems, and ventilation systems in ships.

- Q: How are steel pipes used in the construction of industrial facilities?

- Steel pipes are commonly used in the construction of industrial facilities for various purposes such as transporting fluids, gases, and steam, as well as providing structural support and carrying electrical wiring. They are durable, resistant to corrosion, and can withstand high pressure and temperature, making them ideal for industrial settings.

- Q: How are steel pipes protected during transportation?

- To ensure the safety and integrity of steel pipes during transportation, various measures are taken. One effective approach involves applying protective coatings to the pipes' exteriors. These coatings, such as epoxy or polyethylene, act as barriers against moisture, corrosion, and physical damage. Additionally, bundling the pipes together and securing them with strapping or bands prevents movement and potential collisions while in transit. To provide extra protection against impact and handling, wooden crates or containers may also be used. Furthermore, careful loading and unloading procedures are followed to minimize stress or strain on the pipes. By implementing these protective measures, steel pipes can safely reach their destination without compromising their quality or structural integrity.

- Q: How do you remove rust from steel pipes?

- There exist several methods to eliminate rust from steel pipes: 1. Employ a wire brush or steel wool: Initiate the process by vigorously scrubbing the rusted areas with either a wire brush or steel wool. This action will effectively detach loose rust and flakes from the pipe's surface. 2. Administer vinegar or lemon juice: Immerse a cloth or sponge in white vinegar or lemon juice and generously apply it onto the rusted sections. Allow it to remain undisturbed for several hours or, preferably, overnight. The acidic properties of these substances facilitate the dissolution of the rust. 3. Utilize a rust remover or converter: Numerous rust remover products are readily available on the market. Adhere to the product's instructions and apply it to the affected regions. Typically, these solutions transform rust into a water-soluble compound that can be effortlessly rinsed away. 4. Employ a paste comprising baking soda and water: Combine baking soda with water, creating a thick paste. Apply this paste onto the rusted areas and allow it to sit for a few hours. Proceed to scrub the region using a brush or steel wool before rinsing it off. 5. Experiment with a commercially manufactured rust dissolver: Should the aforementioned approaches fail to yield satisfactory results, it may be worth considering the use of a commercial rust dissolver. These products are specifically designed to eradicate rust from various surfaces, including steel pipes. Comply with the manufacturer's instructions accordingly. Kindly remember to equip yourself with protective gloves, goggles, and a mask when handling rust removal products, as they possess corrosive properties and may release toxic fumes. Furthermore, it is advisable to apply a rust-inhibiting primer or paint subsequent to rust removal to prevent future instances of rusting.

- Q: What is the typical lifespan of steel pipes?

- The typical lifespan of steel pipes can vary depending on various factors such as the quality of the steel used, the environmental conditions, and the maintenance and usage of the pipes. However, on average, steel pipes are known to have a lifespan of around 50 to 100 years. With proper installation, regular inspections, and appropriate maintenance, steel pipes can often exceed this lifespan and provide reliable service for several decades. It is important to note that factors such as corrosion, erosion, and external damage can impact the lifespan of steel pipes, so it is crucial to implement preventive measures and necessary repairs to ensure their longevity.

- Q: What are the different methods of joining steel pipes for oil and gas pipelines?

- There are several methods of joining steel pipes for oil and gas pipelines, including welding, threading, and flanging. Welding involves melting the edges of the pipes together to create a strong bond. Threading involves screwing the pipes together using a threaded connection. Flanging involves using a flange to connect the pipes, which is bolted together with a gasket in between for a secure seal. These methods are commonly used in the construction of oil and gas pipelines to ensure reliable and leak-free connections.

Send your message to us

API Standard Oil and Gas Well Casing Tube K55

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords