1 Inch Wide Anodized Aluminum Strips - Extrusion Aluminum, China Supplier

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

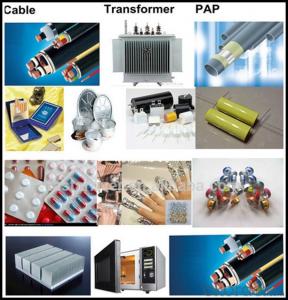

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

Corrosion resistance can be excellent due to a thin surface layer of aluminium oxide that forms when the metal is exposed to air, effectively preventing further oxidation. The strongest aluminium alloys are less corrosion resistant due to galvanic reactions with alloyed copper.This corrosion resistance is also often greatly reduced by aqueous salts, particularly in the presence of dissimilar metals.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: Explain the distinctions between aluminum sheets and aluminum strips.

- <p>Aluminum sheets and aluminum strips are both flat aluminum products, but they differ in width and thickness. Aluminum sheets are wider and can range from 0.2mm to 500mm in thickness, suitable for applications requiring broad surfaces like construction and packaging. Aluminum strips, on the other hand, are narrower and typically used in applications that require thin, elongated pieces, such as in electrical conduits or mechanical parts. The production processes may also vary, with sheets often being rolled and strips being extruded or rolled as well, depending on the specific application and desired properties.</p>

- Q: Is it possible to use aluminum strips as materials for roofing membranes?

- <p>Yes, aluminum strips can be used for roofing membranes. They are known for their durability, corrosion resistance, and lightweight properties, making them suitable for various roofing applications. Aluminum strips can be used in the form of standing seam metal roofs, which are popular for their sleek appearance and strength. They are also low maintenance and can be recycled, contributing to their environmental sustainability. However, it's important to ensure proper installation and sealing to prevent leaks and maintain the integrity of the roof.</p>

- Q: Are aluminum strips suitable for use as interior wall materials?

- <p>Yes, aluminum strips can be used for interior walls. They are known for their durability, resistance to moisture, and ease of installation. Aluminum strips are often used in modern designs for their sleek, contemporary look and can be found in various forms such as aluminum wall panels or as decorative strips. They are low maintenance and do not warp or rot, making them ideal for high-moisture areas like bathrooms and kitchens. However, they may not provide the same insulation or soundproofing as traditional wall materials, so their use may be limited to certain areas or combined with other materials for optimal performance.</p>

- Q: What are the cost differences between aluminum and aluminum strips?

- <p>Aluminum and aluminum strips are both made from the same base material, but their costs can differ due to several factors. Aluminum strips are typically more expensive than bulk aluminum due to the additional processing and manufacturing steps involved in creating them. These steps include rolling, cutting, and sometimes surface treatments, which add to the cost. Additionally, aluminum strips often have tighter tolerances and specific dimensions, which can also increase their price. However, the exact cost difference can vary based on factors such as market prices for aluminum, the complexity of the strip's specifications, and the quantity purchased.</p>

- Q: What is the color of aluminum coating

- Color coated aluminum roll refers to the surface of aluminum alloy coloring treatment, color coated aluminum roll has become one of the most popular top decoration materials. It is a kind of green with environmental protection, durability and beauty.

- Q: This question asks for an overview of the steps involved in the manufacturing of aluminum components used in vehicles.

- <p>The production process of automotive aluminum parts typically involves several key steps: material selection, design, casting or forging, machining, heat treatment, surface treatment, and quality control. Aluminum is chosen for its lightweight and high strength properties. The design phase involves creating detailed plans for the part. Casting or forging shapes the aluminum into rough forms. Machining refines these forms to precise specifications. Heat treatment enhances strength and durability. Surface treatments protect against corrosion and wear. Finally, quality control ensures each part meets industry standards before it is used in vehicles.</p>

- Q: What are the potential drawbacks or negative aspects of utilizing aluminum strips as a material for exterior siding on a building?

- <p>Aluminum siding, while durable and lightweight, has several disadvantages. It can dent easily due to its softness, which may require frequent repairs. It also lacks insulating properties, leading to increased energy costs as it doesn't retain heat well. Additionally, aluminum siding can be noisy during heavy rain or hail, and it may expand and contract with temperature changes, causing warping or gaps. Furthermore, it can be more expensive than some other materials, and its reflective nature may lead to a less aesthetically pleasing appearance compared to other siding options.</p>

- Q: This question asks for the various factors that can influence the pricing of aluminum strips.

- <p>The price of aluminum strips is influenced by several factors, including the global supply and demand dynamics, the price of aluminum on the commodities market, production costs, transportation expenses, tariffs and trade policies, market competition, and economic conditions. Additionally, the quality and specifications of the aluminum strips, such as purity and thickness, can also affect pricing. Fluctuations in energy costs, especially for electricity used in the smelting process, can impact production costs and, consequently, the price of aluminum strips. Lastly, geopolitical events and environmental regulations can also have an indirect effect on the availability and cost of aluminum, thus influencing strip prices.</p>

- Q: What are the distinctions between pure aluminum and its alloys?

- <p>Aluminum and aluminum alloys have distinct properties. Pure aluminum is a soft, lightweight metal with good thermal and electrical conductivity. It is highly reflective and resistant to corrosion. Aluminum alloys, on the other hand, are made by combining aluminum with other elements such as copper, magnesium, or silicon to enhance its strength, durability, and resistance to heat and wear. These alloys are stronger and more versatile than pure aluminum, making them suitable for a wide range of applications, from aerospace to construction.</p>

- Q: What specific cleaning techniques should be employed for maintaining an aluminum strip roof?

- <p>When cleaning an aluminum strip roof, it's important to use gentle cleaning methods to avoid damaging the metal. Use a soft brush or broom to remove debris and avoid using abrasive tools that could scratch the surface. For cleaning solutions, opt for mild detergents mixed with water, and avoid harsh chemicals that could corrode the aluminum. Always rinse thoroughly to remove any residue. Never use high-pressure water or steam cleaners, as they can cause dents or warp the aluminum. Regular maintenance, such as checking for and sealing any leaks, will also help prolong the life of your aluminum strip roof.</p>

Send your message to us

1 Inch Wide Anodized Aluminum Strips - Extrusion Aluminum, China Supplier

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords