Colorful Aluminum Carpet Transition Strips - Anodized Extrusion Aluminum, China Supplier

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

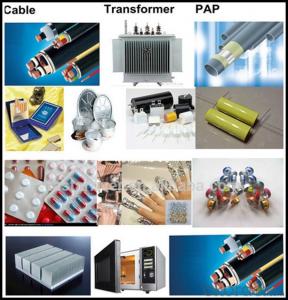

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, , kitchens and balconies, shutters, doors...

(1).Interior: shutters, bathrooms,doors...

(2).Exterior: renovations...

(3).Advertisement: fascia, shop fronts...

3. Feature of Aluminum

Another important property of aluminium alloys is their sensitivity to heat. Workshop procedures involving heating are complicated by the fact that aluminium, unlike steel, melts without first glowing red. Forming operations where a blow torchis used therefore require some expertise, since no visual signs reveal how close the material is to melting.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

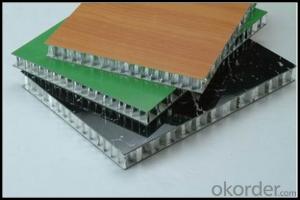

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: This question asks for a method to measure the thickness of aluminum siding material.

- <p>To determine the thickness of aluminum siding, you can use a digital caliper or a micrometer, which are precise measuring tools. Place the caliper or micrometer at the edge of the siding, ensuring it's perpendicular to the surface, and take a measurement. Another method is to use a magnetic thickness gauge if the siding is coated, as this tool can measure the thickness of non-magnetic coatings on magnetic metals. Always check the manufacturer's specifications for the siding as well, as they often provide thickness information.</p>

- Q: Is it possible to utilize aluminum strips for a personal roofing project?

- <p>Yes, you can use aluminum strips for your own roofing project. Aluminum is a popular choice due to its durability, lightweight, and resistance to corrosion. It's easy to work with and can be cut and shaped to fit various roofing designs. However, it's crucial to ensure proper installation, as aluminum expands and contracts with temperature changes, requiring appropriate fastening and sealing to prevent leaks. Always follow local building codes and consult with a professional if you're unsure about the installation process.</p>

- Q: This question asks for the cost of aluminum strip roofing, which is a type of metal roofing material.

- <p>The cost of aluminum strip roofing can vary significantly based on factors such as the quality of the aluminum, the complexity of the installation, and regional pricing. On average, the cost of aluminum strip roofing ranges from $6 to $12 per square foot for the materials alone. This does not include labor costs, which can add another $3 to $10 per square foot. It's important to get quotes from multiple contractors in your area to get an accurate estimate for your specific project. Prices can fluctuate, so it's best to check current market rates for the most up-to-date information.</p>

- Q: What is the ease of bending aluminum strips and what factors might affect this?

- <p>Aluminum strips can be bent relatively easily due to their malleability. The ease of bending depends on the alloy type, thickness, and temperature. Pure aluminum is softer and more ductile, making it easier to bend than aluminum alloys. Thinner strips are also easier to bend than thicker ones. Heating aluminum can increase its ductility, making it easier to bend without breaking. However, excessive force or improper bending can cause the strip to crack or deform.</p>

- Q: What are the regular maintenance concerns associated with aluminum siding on buildings?

- <p>Aluminum siding is generally low-maintenance, but there are a few issues that may require attention. These include checking for dents or damage caused by impacts, ensuring proper drainage to prevent water damage, and cleaning to remove dirt and grime that can dull the finish. Additionally, it's important to inspect for signs of corrosion, especially in coastal areas with high salt content, and to address any loose or peeling paint to prevent further damage. Regular inspection and minor repairs can help maintain the longevity and appearance of aluminum siding.</p>

- Q: Can aluminum strips withstand harsh conditions like high humidity or salt spray?

- <p>Aluminum strips can be used in harsh environments to some extent, but their performance may be compromised. Aluminum is resistant to corrosion, making it suitable for high humidity conditions. However, in environments with significant salt spray exposure, aluminum can corrode over time, particularly due to the formation of galvanic cells when in contact with other metals. Protective coatings or anodizing can enhance its corrosion resistance, but it's not entirely impervious. Thus, while aluminum can be used in such environments, it requires proper protection and maintenance to ensure longevity.</p>

- Q: Is it possible to use aluminum strips as a material for exterior wall cladding?

- <p>Yes, aluminum strips can be used for exterior cladding. They are known for their durability, resistance to corrosion, and low maintenance requirements. Aluminum cladding is lightweight, which makes it easier to install compared to heavier materials. It also offers excellent weather resistance and can be painted or finished in various ways to enhance the appearance of a building. Additionally, aluminum is a sustainable choice as it can be recycled, contributing to environmental sustainability.</p>

- Q: What effect does the aluminum pulley bring to the belt?

- The timing belt pulley is aluminum. Friction wheel? Not seen with aluminum, may be too hot, aluminum easy adhesion, resulting in increased friction

- Q: What factors should be considered to determine if an aluminum strip is suitable for a specific application?

- <p>To determine if a certain type of aluminum strip is suitable for your application, consider the following factors: mechanical properties such as strength and ductility, corrosion resistance, thermal conductivity, and electrical conductivity. Assess the strip's dimensional tolerances and surface finish to ensure they meet your requirements. Check if the strip's formability and weldability align with your manufacturing processes. Also, consider the strip's weight and cost-effectiveness. It's advisable to consult with a material scientist or supplier who can provide specific recommendations based on your application's unique needs.</p>

- Q: The user is asking whether they should hire a professional to install aluminum strip products or if they can do it themselves.

- <p>Whether to hire a professional or do it yourself depends on your experience and comfort level with DIY projects. If you are skilled in construction or have experience with similar installations, you may be able to install aluminum strip products yourself. However, if you lack the necessary skills or are unsure about the process, hiring a professional installer is recommended. Professionals have the expertise to ensure a proper and secure installation, which can save you time and potential complications down the line. Additionally, they can handle any unexpected issues that may arise during the installation process.</p>

Send your message to us

Colorful Aluminum Carpet Transition Strips - Anodized Extrusion Aluminum, China Supplier

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords