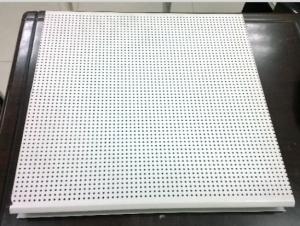

Colorful Anodized Aluminum Extrusion - Perforated Aluminum Strips

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

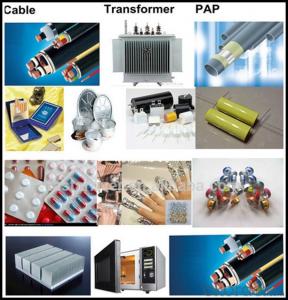

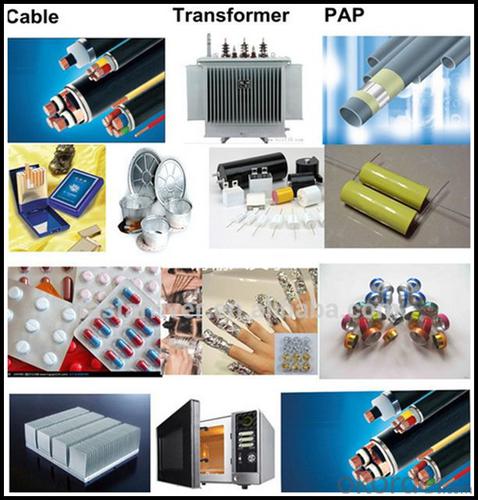

2. Application of Aluminum

(1).Interior: shutters, doors...

(2).Exterior: renovations aluminium fluorosilicate ...

(3).Advertisement: fascia, shop fronts...

3. Feature of Aluminum

Organoaluminiums are used as Lewis acids and cocatalysts. For example, methylaluminoxane is a cocatalyst forZiegler-Natta olefin polymerization to produce vinyl polymers such as polyethene. Aqueous aluminium ions (such as found in aqueous aluminium sulfate) are used to treat against fish parasites such as Gyrodactylus salaris. In many vaccines, certain aluminium salts serve as an immune adjuvant (immune response booster) to allow the protein in the vaccine to achieve sufficient potency as an immune stimulant.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

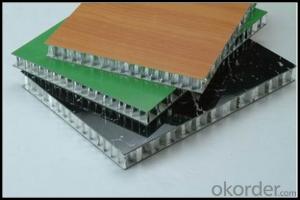

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: This question asks whether aluminum strips are suitable for use in cold weather conditions.

- <p>Aluminum strips are generally suitable for cold climates. Aluminum has a low coefficient of thermal expansion, which means it doesn't expand or contract significantly with temperature changes. This property makes it resistant to the effects of cold weather. Additionally, aluminum is lightweight, durable, and corrosion-resistant, which are desirable traits in materials used in cold environments. However, it's important to consider specific applications and the quality of the aluminum strip, as certain alloys or treatments may affect performance in extreme cold.</p>

- Q: Inquiring about the durability of aluminum strips.

- <p>Aluminum strips are known for their durability. They are resistant to corrosion and weathering, making them suitable for long-term use in various environments. Their strength and light weight also contribute to their durability, allowing them to withstand significant stress without breaking. However, their longevity can be affected by factors such as the quality of the aluminum, the manufacturing process, and the specific conditions they are exposed to. Proper maintenance and handling can further enhance their durability.</p>

- Q: Is it possible to use aluminum strips as a material for flooring?

- <p>Aluminum strips can indeed be used for flooring, particularly in industrial or commercial settings where durability and resistance to wear are important. They are known for their strength, low maintenance, and resistance to corrosion. Aluminum strips are often used in modular flooring systems, providing a sleek and modern appearance. However, they may not be as common or suitable for residential applications due to concerns about thermal conductivity, noise, and the potential for a cold, hard feel underfoot.</p>

- Q: Is it possible to utilize aluminum strips in a construction project focused on sustainability and environmental responsibility?

- <p>Yes, you can use aluminum strips for a green building project. Aluminum is a versatile and sustainable material due to its recyclability and low energy consumption in production. It also has a high strength-to-weight ratio, which can contribute to the energy efficiency of a building. However, it's important to consider the source of the aluminum and ensure it is produced with minimal environmental impact. Using recycled aluminum can further enhance the green credentials of your project.</p>

- Q: What are the environmentally friendly options for aluminum strips?

- <p>Yes, there are environmentally friendly types of aluminum strips. Recycled aluminum strips are more eco-friendly as they require significantly less energy to produce compared to virgin aluminum. Additionally, using aluminum strips with a high recycled content reduces waste and conserves natural resources. Another option is to look for aluminum strips that are produced using renewable energy sources, which further reduces their carbon footprint. Lastly, choosing aluminum strips with a lower coating or treatment that is biodegradable or has a lower environmental impact can also contribute to their environmental friendliness.</p>

- Q: Is it possible to utilize aluminum strips in constructing a rainscreen wall system?

- <p>Yes, aluminum strips can be used to create a rainscreen wall system. Aluminum is a popular choice due to its durability, resistance to corrosion, and low maintenance requirements. It allows for proper ventilation and drainage behind the cladding, which helps prevent moisture damage and thermal stress. When designing a rainscreen system with aluminum strips, ensure that the installation follows building codes and standards, and that the strips are properly spaced and sealed to maintain the system's effectiveness.</p>

- Q: 1060 what is the hardness of aluminum strip?

- Brinell hardness measurement method is to use a hardened steel ball, such as the diameter of 5 mm steel ball, with a certain force into the parts or material surface, and then measure the indentation size, read the hardness value.

- Q: Does aluminum maintain its properties and resist damage from fire?

- <p>Aluminum strips are relatively fire-resistant, but not completely immune to damage. Aluminum has a high melting point of approximately 660掳C (1220掳F), which means it can withstand high temperatures without melting. However, it can still oxidize and corrode at elevated temperatures, leading to a loss of structural integrity over time. While it may not catch fire, it can still be affected by prolonged exposure to fire, and its performance can degrade depending on the specific conditions and the protective measures in place.</p>

- Q: What is the chemical composition represented by the formula for aluminum strips?

- <p>The chemical formula for aluminum strips is simply Al. Aluminum is a chemical element with the symbol Al and atomic number 13. It is a silvery-white, soft, nonmagnetic, and ductile metal in group 13 of the periodic table. Aluminum strips are made of this single element and do not contain any other elements or compounds.</p>

- Q: This question asks if there are different types of aluminum with varying levels of electrical conductivity.

- <p>Aluminum, as a pure element, has a consistent electrical conductivity. However, its conductivity can be affected by the presence of impurities or alloying elements. In general, the higher the purity, the better the conductivity. Alloys like 1100 aluminum (99.00% pure) have the highest conductivity among aluminum alloys. Adding elements like copper, magnesium, or silicon to aluminum can increase its strength but will decrease its conductivity. Therefore, while there isn't a 'better' type of aluminum in terms of conductivity, there are alloys with varying levels of conductivity based on their composition and purity.</p>

Send your message to us

Colorful Anodized Aluminum Extrusion - Perforated Aluminum Strips

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords