Gold Aluminum Strips with Alloy 1070 1060 in Different Widths for Transformer or Ceiling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

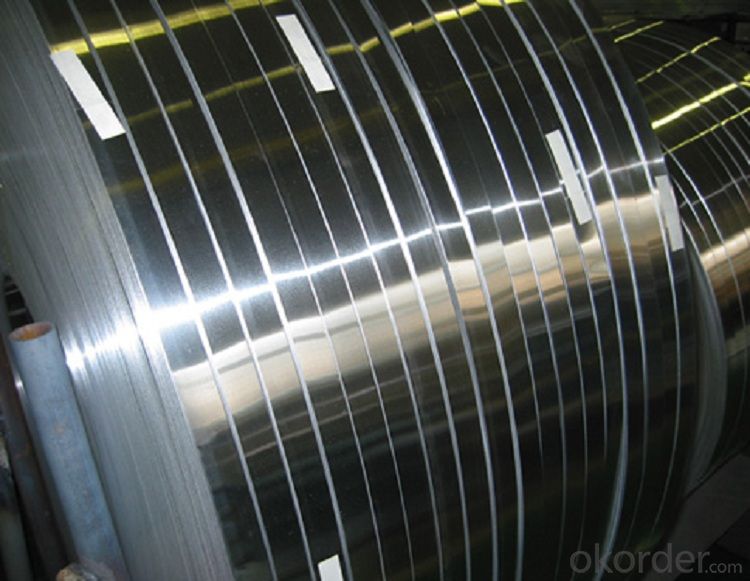

l Product Introduction

The Aluminum Strip is mainly used for refrigerator, cable ,capacitor shell material, steal-protection cover, cable sheathing, composite pipe and tube, water pipe etc. It has the property of deep drawing, high thickness accuracy, and low earring rate, etc.

l Specifications

| Aluminum Strips with Alloy1070 1060 in Differet Width for Transformer or Ceiling | |||||

| PRODUCT | ALLOY | THICKNESS | WIDTH | STANDARD | APPLICATION |

| aluminum strip | 1060 1100 3003 5052 5005 8011 | 0.12-4.0mm | 30mm-1600mm | GB/T 3880-2006 | For cable, cosmetic cap, aluminum composite pipe, aluminum hose or tube, electrical transformer, shutter, aluminum battery, etc. |

l Packaging & Delivery

Packaging detail: Covering with brown paper and plastic bag then packed with wooden plywood then directly loading into container for transshipment. For the thickness which is more than 1.50mm, one paper interleave into two sheets.

Delivery detail: within 30days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

The business scope of CNBM covers from manufacturing and sales of a series of building materials to scientific research and design, import and export trade. In many of these fields, CNBM is playing the leading role.

l CNBM World Wide

l Product Images

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: This question asks for a comparison of various types of aluminum siding used in construction, highlighting their unique characteristics and differences.

- <p>Aluminum siding comes in various types, each with unique properties. Interlock siding features overlapping panels for better protection against weather. Insulated siding offers thermal efficiency with a foam core. Vertical siding is known for its traditional look and is often used in commercial settings. Shake-style siding mimics the appearance of wood shakes, providing a rustic aesthetic. Soffit siding is designed for use around windows and eaves, offering a clean finish. Each type varies in terms of durability, maintenance requirements, and cost, with applications ranging from residential to commercial construction.</p>

- Q: This question asks for the steps to attach aluminum strips to a wall or roof surface.

- <p>To install aluminum strips on a wall or roof, first measure and mark the area where you want to install the strips. Ensure the surface is clean and dry. Apply a suitable adhesive or use screws, depending on the type of strip and surface. Align the first strip and press firmly or secure with screws. For subsequent strips, use a spacer if needed to maintain consistent spacing. Check alignment regularly and ensure all strips are level. Seal any gaps with appropriate sealant and finish with a protective coating if required. Always follow the manufacturer's instructions for the specific product you are using.</p>

- Q: Is it possible to utilize aluminum strips as materials for constructing roofs?

- <p>Yes, aluminum strips can be used for roofing materials. They are known for their durability, resistance to corrosion, and lightweight properties. Aluminum is also recyclable and can be coated with various finishes to enhance its appearance and performance. It is often used in modern architecture for its sleek look and low maintenance requirements. However, it's important to ensure that the aluminum strips are properly installed and meet building codes for safety and effectiveness.</p>

- Q: Is it possible to apply paint to aluminum strips?

- <p>Yes, aluminum strips can be painted. However, proper surface preparation is crucial for good adhesion and durability of the paint. This typically involves cleaning the aluminum to remove any grease or contaminants, followed by etching or using a primer designed for aluminum to promote better paint adherence. After priming, the aluminum can be painted with a suitable paint, such as acrylic or epoxy, which are known for their compatibility with metal surfaces. It's important to follow the manufacturer's instructions for the specific paint and primer used to ensure the best results.</p>

- Q: Is there any health risk associated with the use of aluminum in food packaging?

- <p>There are some concerns about the use of aluminum in food packaging due to its potential to leach into food, especially when in contact with acidic foods. Aluminum exposure has been linked to neurological disorders, including Alzheimer's disease, although the evidence is not conclusive. The World Health Organization states that while there is no clear risk from dietary aluminum, further research is needed. It's important to note that aluminum is naturally present in many foods and drinking water, and the body can only absorb a small amount of aluminum from food packaging. Most aluminum exposure comes from natural sources, not from packaging.</p>

- Q: Explain the environmental effects of utilizing recycled aluminum.

- <p>The use of recycled aluminum has a significant positive impact on the environment. It reduces the need for mining bauxite, which is the primary source of aluminum, thereby decreasing deforestation and habitat destruction. Recycling aluminum also conserves energy, as it requires only 5% of the energy needed to produce aluminum from raw materials. This energy conservation leads to reduced greenhouse gas emissions, contributing to the fight against climate change. Additionally, recycling aluminum reduces the amount of waste sent to landfills, lessening the environmental burden of waste disposal. Overall, the use of recycled aluminum promotes sustainability and helps protect natural resources.</p>

- Q: What are the distinctions between pure aluminum and its alloys?

- <p>Aluminum and aluminum alloys have distinct properties. Pure aluminum is a soft, lightweight metal with good thermal and electrical conductivity. It is highly reflective and resistant to corrosion. Aluminum alloys, on the other hand, are made by combining aluminum with other elements such as copper, magnesium, or silicon to enhance its strength, durability, and resistance to heat and wear. These alloys are stronger and more versatile than pure aluminum, making them suitable for a wide range of applications, from aerospace to construction.</p>

- Q: What are the typical applications of aluminum strips within the construction industry?

- <p>Aluminum strips are commonly used in construction for various purposes due to their strength, durability, and lightweight properties. They are often used as a component in the manufacturing of aluminum windows and doors for their high strength-to-weight ratio and resistance to corrosion. Aluminum strips are also utilized in the construction of curtain walls, which are the outer coverings of buildings, for their aesthetic appeal and low maintenance requirements. Additionally, they are employed in roofing systems for their ability to withstand harsh weather conditions and resist rust. Furthermore, aluminum strips are used in the framing of buildings and in the creation of structural supports due to their high tensile strength.</p>

- Q: This question asks for methods to prevent rusting on aluminum strips during both installation and use.

- <p>To prevent rusting on aluminum strips, ensure that the aluminum is of high quality and free from impurities. Keep the strips clean and dry during installation and use. Avoid contact with corrosive substances. Apply a protective coating or sealant if necessary. Regularly inspect and clean the aluminum strips to remove any dirt or moisture that could lead to corrosion. In case of scratches or damage, promptly repair and seal the affected areas to prevent moisture penetration.</p>

- Q: Explain the use of aluminum strips in the automotive industry briefly.

- <p>Aluminum strips are widely used in the automotive industry due to their lightweight, corrosion resistance, and high strength-to-weight ratio. They are commonly used in the manufacturing of car bodies, engine parts, and heat exchangers. Aluminum strips are also utilized in the production of wheels, where their lightweight nature contributes to improved fuel efficiency and performance. Additionally, they are employed in the construction of radiators, air conditioning systems, and various electrical components due to their excellent thermal conductivity and electrical properties. The use of aluminum strips in automotive applications helps reduce vehicle weight, which in turn enhances fuel economy and reduces emissions.</p>

Send your message to us

Gold Aluminum Strips with Alloy 1070 1060 in Different Widths for Transformer or Ceiling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords