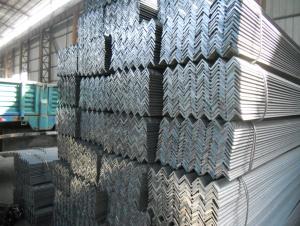

ANGLE BAR

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Angle Steel

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

6.Material details:

Alloy No | Grade | Element (%) | | ||||

C | Mn | S | P | Si | | ||

| | |||||||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | | ||||

Thickness (mm) | | ||||||

≤16 | >16--40 | >40--60 | >60--100 | | |||

≥ | | ||||||

|

|

|

|

|

| | |

Q235 | B | 235 | 225 | 215 | 205 | | |

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | | |||

Thickness (mm) | | ||||||

| ≤16 | >16--40 | >40--60 | >60--100 | | ||

≥ | | ||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications of Angle Steel

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: How do steel angles contribute to the overall stability of a building?

- Steel angles contribute to the overall stability of a building by providing structural support and reinforcement. They are commonly used to reinforce corners and joints in construction, helping to distribute the load and prevent the building from collapsing or experiencing excessive movement during strong winds, earthquakes, or other external forces. The angled shape of steel angles also helps to increase the rigidity and strength of the building's framework, enhancing its overall stability and durability.

- Q: How do steel angles contribute to the overall durability of a structure?

- Angle irons, also known as steel angles or L-shaped structural steel, play a crucial role in strengthening structures and improving their durability. These versatile components are commonly used in construction projects because they provide strength, stability, and support. To begin with, steel angles are designed to bear heavy loads and forces. They evenly distribute the weight, preventing structural failures and ensuring the longevity of the building. This is especially important in situations where the structure is exposed to dynamic forces like wind, earthquakes, or heavy machinery. Furthermore, steel angles act as effective reinforcements in critical areas of a structure. They reinforce connections between different structural members, such as beams and columns, creating a strong framework. This reinforcement enhances the overall load-bearing capacity of the structure, allowing it to withstand greater loads without compromising its integrity. Moreover, steel angles offer lateral stability to buildings. By diagonally connecting various components, they resist horizontal forces caused by wind or seismic activity. This lateral stability is vital in preventing the structure from swaying or collapsing under extreme conditions, ensuring the safety of occupants. Additionally, steel angles have high resistance to corrosion, a common cause of structure deterioration. Using galvanized or stainless steel angles significantly reduces the risk of rusting and subsequent degradation. This corrosion resistance contributes to the long-term durability of the structure, reducing maintenance costs and extending its lifespan. In conclusion, steel angles are vital for enhancing the overall durability of structures due to their ability to withstand heavy loads, provide reinforcement, offer lateral stability, and resist corrosion. By incorporating steel angles into construction projects, engineers can ensure the structural integrity and longevity of buildings, ultimately creating safer and more durable spaces.

- Q: Can steel angles be used in mezzanine construction?

- Yes, steel angles can be used in mezzanine construction. Steel angles are often used as structural supports in mezzanine construction due to their strength and versatility. They can be used to create the framework and provide stability for mezzanine floors, making them a popular choice in this type of construction.

- Q: How do steel angles differ from other structural shapes?

- Steel angles possess several distinguishing characteristics that set them apart from other structural shapes. Firstly, their cross-section takes on a distinct L-shape, featuring two perpendicular flanges and a central web connecting them. This exceptional shape grants the angle exceptional strength and load-bearing capacity, rendering it suitable for a myriad of structural applications. Secondly, steel angles exhibit remarkable versatility, finding utility in a wide array of construction projects. They can be effortlessly welded, bolted, or screwed together to forge intricate structures like frames, supports, and bracings. This adaptability endows them with a favored status among engineers and architects. Furthermore, steel angles come in various sizes and thicknesses, allowing for customization tailored to precise project requirements. This assortment in dimensions streamlines the attainment of desired strength and stability in structural designs. Moreover, steel angles provide cost-effective solutions in comparison to alternative structural shapes. Their resourceful utilization of materials and manufacturing processes renders them relatively affordable, all while maintaining their durability and functionality. Lastly, steel angles exhibit an impressive capacity to withstand substantial loads and stresses, making them an idyllic choice for applications where structural integrity is of paramount importance. Their ability to evenly distribute weight across the flanges and web ensures stability and prevents deformation under heavy loads. In conclusion, steel angles epitomize unique structural shapes, endowing construction projects with strength, versatility, customizability, cost-effectiveness, and durability. These attributes distinguish them from other structural shapes, rendering them an excellent choice for diverse construction endeavors.

- Q: What are the environmental benefits of using steel angles?

- The environmental benefits of using steel angles include their high strength and durability, which allows for longer lifespan and reduced need for replacement. Steel angles are also recyclable, contributing to a circular economy by reducing the demand for raw materials and energy consumption. Furthermore, steel angles can be manufactured using recycled steel, reducing the carbon footprint and promoting sustainable practices in the construction industry.

- Q: What are the different types of surface defects in steel angles?

- Some common types of surface defects in steel angles include pitting, scaling, scratches, and rust.

- Q: How do steel angles perform in terms of electromagnetic shielding?

- Steel angles have a reputation for being highly effective in terms of electromagnetic shielding. This is mainly because of their exceptional electrical conductivity and magnetic permeability. These particular qualities enable steel angles to efficiently redirect or absorb electromagnetic waves, resulting in a reduced impact on adjacent electronic devices or sensitive equipment. The shape and geometry of steel angles also play a role in their shielding capabilities, as they can be strategically positioned to create barriers or enclosures that obstruct or redirect electromagnetic fields. Additionally, the thickness or gauge of the steel angle can further amplify its shielding performance. In general, steel angles find widespread use in a variety of applications where minimizing or controlling electromagnetic interference is crucial, such as in the construction, telecommunications, electronics, and automotive industries.

- Q: Can steel angles be used in the construction of railway bridges?

- Yes, steel angles can be used in the construction of railway bridges. Steel angles are versatile structural elements that can be used in various applications, including bridge construction. They are commonly used in the fabrication of bridge girders, braces, and supports. Steel angles provide excellent strength and load-bearing capabilities, making them suitable for railway bridges that require high structural integrity and durability. Additionally, steel angles can be easily welded, bolted, or riveted together, allowing for efficient and cost-effective construction. Overall, steel angles are a viable and commonly used component in the construction of railway bridges.

- Q: How do steel angles perform in terms of durability and longevity?

- Steel angles are renowned for their exceptional durability and longevity. Due to their composition, which includes a high percentage of iron and carbon, steel angles possess remarkable strength and resistance to various forms of wear and tear. They can withstand heavy loads, extreme temperatures, and exposure to corrosive elements, making them highly durable in a wide range of applications. In terms of longevity, steel angles have an impressive lifespan. They are designed to withstand the test of time and retain their structural integrity over extended periods. The inherent strength and resilience of steel angles ensure that they do not degrade easily, making them a reliable choice for long-term use. Furthermore, steel angles require minimal maintenance to preserve their durability and longevity. Regular inspections and cleaning can help prevent the buildup of rust and other forms of corrosion, ensuring that the angles remain in optimal condition throughout their lifespan. Moreover, steel angles can be galvanized or coated with protective layers to enhance their durability and resistance to environmental factors. Galvanization involves applying a layer of zinc to the steel surface, providing an additional barrier against rust and corrosion. Coatings such as epoxy or powder coatings can also be applied to further enhance the durability and longevity of steel angles in specific environments. Overall, steel angles are known for their exceptional durability and longevity. They offer a reliable and long-lasting solution for a variety of structural and construction needs, making them a popular choice in many industries.

- Q: What are the safety precautions when working with steel angles?

- To minimize the risk of accidents and injuries when working with steel angles, it is crucial to follow specific safety measures. Here are some essential considerations: 1. Personal Protective Equipment (PPE) is essential. Make sure to wear safety glasses, gloves, steel-toed boots, and a hard hat to protect yourself from potential hazards like flying debris, sharp edges, and falling objects. 2. Proper handling is key. Utilize mechanical aids such as cranes or forklifts to lift and move heavy steel angles. Avoid manual lifting if the weight exceeds your capacity. Ensure secure stacking of angles and avoid overloading shelves or racks. 3. Organize and keep the work area clean to prevent accidents. Remove any obstructions or clutter that may hinder movement. Clearly mark areas where steel angles are stored or being worked on to prevent unauthorized access. 4. Regularly inspect and maintain tools and equipment used to work with steel angles. Repair or replace any defects promptly and avoid using damaged or faulty equipment. 5. When cutting or grinding steel angles, wear appropriate eye and face protection to shield against sparks, dust, and debris. Use tools specifically designed for cutting and grinding steel. Ensure proper ventilation in enclosed spaces to minimize the risk of inhaling toxic fumes. 6. Store steel angles in a designated area where they are secure and not at risk of falling or causing accidents. Use racks or shelves suitable for supporting the weight and size of the angles. Securely stack and strap them to prevent toppling over. 7. Implement proper fire safety measures. Steel angles can generate sparks when cut or welded. Have fire extinguishers and fire-resistant materials nearby. Keep flammable substances away from the work area. 8. Provide adequate training to all workers handling steel angles. Ensure they understand safety precautions, procedures, and emergency protocols. Encourage open communication and reporting of safety concerns or incidents. By following these safety precautions, you can create a safer working environment and minimize the risk of accidents when handling steel angles. Always prioritize your safety and the safety of others in your work with steel angles.

Send your message to us

ANGLE BAR

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords