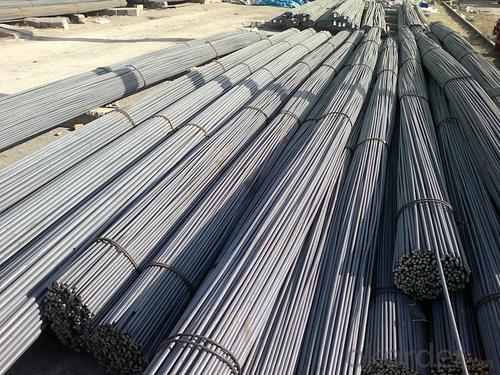

ROUND BAR

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Wire Rod Q235:

Steel Grade: Q235, Standard: GB Diameter: 5.5mm, 6.5mm, 7mm,8mm,9mm,10mm,12mm,14mm

Diameter Tolerance:±0.3mm 6.5mm can be drawing into 2mm/8.0mm can be drawing into 3mm

Brand Name: N-RIVER Place of Origin: Hebei, China Mainland Application: construction, building etc

Chemical Composition:

Please kindly find our chemistry of our material based on Q235 as below for your information

Trademark | Rank | Chemical composition (quality score) % | | ||||

C | Si | Mn | S | P | | ||

| | |||||||

| ≤ |

| ≤ | ≤ | | ||

Q235 | A | 0.14-0.22 | 0.30 | 0.30-0.65 | 0.050 | 0.045 | |

Q235 | B | 0.12-0.20 | 0.30 | 0.30-0.70 | 0.045 | 0.045 | |

Trademark | Rank | Pulling Test | | ||||

Bend PointΔs/Mpa | Tensile Strength | Elongation Ratioδ5% | | ||||

| | |||||||

Thickness (Diameter) /MM | Thickness (Diameter) /MM | | |||||

≤16 | 16-40 | | ≤16 | 16-40 | | ||

≥ | | ≥ | | ||||

Q235 | A | 235 | 225 | 375-500 | 26 | 25 | |

Q235 | B | 235 | 225 | 375-500 | 26 | 25 | |

Usage and Applications of Wire Rod Q235:

After hot-rolled the products shaped into coil and delivery as finished product, including round, square, rectangular, hexagonal and so on. Since most of the products are round, it is generally called wire rod. Carbon steel wire rod is widely used in construction and manufacturing. Carbon steel wire rod is mainly used for reinforcement of reinforced concrete and welded structure or reprocessed (roberts , nail, etc.) materials, especially used to produce wire drawing, welding electrode, nails, spring, electronic, precise machinery parts and so on.

Packaging & Delivery of Wire Rod Q235:

Packaging Detail: products are packed in coil and then shipped by container or bulk vessel

Each coil weight: 2-3MT

Delivery Detail: within 45 days after received deposit or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

- Q: Can steel round bars be used in food processing applications?

- No, steel round bars are not suitable for food processing applications as they can corrode and contaminate the food. Stainless steel is typically used in such applications due to its corrosion resistance and hygienic properties.

- Q: Can steel round bars be used in the production of musical equipment?

- Musical equipment production can indeed incorporate steel round bars. Steel, being a robust and long-lasting substance, is frequently employed in constructing diverse musical instruments. Structural features like frames, braces, and supports for guitars, drums, and pianos can all be fashioned from steel round bars. Furthermore, steel can be utilized to manufacture sound-enhancing components such as resonators or bellows in certain instruments. The adaptability and dependability of steel render it an appropriate selection for the production of musical equipment.

- Q: How do steel round bars perform under cyclic loading?

- Steel round bars generally perform well under cyclic loading due to their high strength and ductility. The ability of steel to withstand repeated loading and unloading without significant deformation or failure makes it suitable for applications where cyclic loading is present, such as in structural engineering, automotive components, and machinery. However, the performance of steel round bars under cyclic loading also depends on factors like the quality of the steel, design considerations, and the magnitude and frequency of the cyclic loading.

- Q: Can steel round bars be machined using CNC equipment?

- Indeed, CNC equipment is capable of machining steel round bars. By utilizing computer programs to govern the movement of cutting tools, CNC machines can execute a vast array of operations on diverse materials, including steel round bars. These operations encompass turning, milling, drilling, and threading, effectively achieving the desired shape, dimensions, and surface finish. Notably, CNC machines exhibit exceptional repeatability, consistency, and efficiency, rendering them an optimal selection for machining steel round bars in industries such as automotive, aerospace, construction, and manufacturing.

- Q: What are the advantages of using steel round bars compared to other materials?

- There are several advantages to using steel round bars compared to other materials. Firstly, steel is known for its strength and durability, making it ideal for heavy-duty applications. It can withstand high temperatures, pressure, and heavy loads without warping or breaking. Secondly, steel round bars are highly versatile and can be easily machined, welded, and formed into various shapes and sizes, making them suitable for a wide range of applications. Additionally, steel is a cost-effective option as it provides excellent long-term value due to its durability and low maintenance requirements. Lastly, steel is a sustainable and environmentally friendly material as it can be recycled and reused indefinitely without losing its properties.

- Q: Can steel round bars be used in corrosive environments?

- Steel round bars can be used in corrosive environments depending on the specific grade of steel and the severity of the corrosive conditions. Stainless steel round bars, for example, have high resistance to corrosion and are commonly used in corrosive environments. However, regular carbon steel round bars may be susceptible to corrosion and would require additional protective coatings or treatments to be used effectively in such conditions.

- Q: The problem of dowel bars on concrete pavements?

- Light bar shall be adopted for dowel barWith transverse expansion joint as an example: in the face of layer thickness is 220mm, dowel diameter is 28mm (28), the minimum length of the dowel bar is 400mm, the maximum dowel bar spacing is 300mm.

- Q: Can steel round bars be used for making crankshafts?

- Yes, steel round bars can be used for making crankshafts. Steel is a commonly used material for crankshafts due to its high strength, durability, and ability to withstand the stresses and strains of engine operation. The round bars can be machined and shaped to the required specifications to create a reliable and functional crankshaft.

- Q: How are steel round bars measured and specified?

- The diameter is utilized to measure and specify steel round bars. Typically, the diameter of a round bar is measured in millimeters or inches. The measurement is taken at the widest point of the circular cross-section. When it comes to specification, steel round bars are commonly specified by their diameter and length. For instance, a steel round bar can be specified as "25mm diameter x 3 meters length". This indicates that the bar has a diameter of 25mm and a length of 3 meters. Moreover, steel round bars can also be specified based on their tolerance, surface finish, and grade. Tolerance refers to the allowable deviation from the specified diameter. Surface finish pertains to the quality of the bar's surface, which can vary from rough to smooth. Grade signifies the quality and composition of the steel utilized to produce the round bar, such as mild steel, carbon steel, or alloy steel. Accurate measurement and specification of steel round bars are crucial to ensure that they meet the necessary dimensions and properties for a specific application.

- Q: What are the advantages of using structural steel round bars?

- There are several advantages of using structural steel round bars. Firstly, they provide excellent strength and durability, making them suitable for various structural applications. Additionally, their round shape allows for easy fabrication and installation, reducing construction time and costs. Steel round bars also have a high resistance to corrosion and can withstand extreme weather conditions. Moreover, they offer versatility in design as they can be easily bent, shaped, and welded to meet specific project requirements. Lastly, steel round bars are widely available and can be recycled, making them a sustainable choice for construction projects.

Send your message to us

ROUND BAR

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords