Aluzinc Steel Sheet in Coil with Prime Quality and Lowest Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluzinc Steel Coil Description:

Hotdip aluzinc steel sheet is substrated on cold rolled steel(CRC) in various strength and specification. Coating composition is 55% aluminium in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent corrosion and heat resistance performance. It is especially useful for countless outdoor and industrial applications.

2.Main advantages of the Galvanized Steel Coil:

• Base material for countless outdoor and industrial applications

• Excellent corrosion resistance

• Excellent heat resistance performance

• High strength

• Good formability

• Rust- proof ability

• Good visual effect

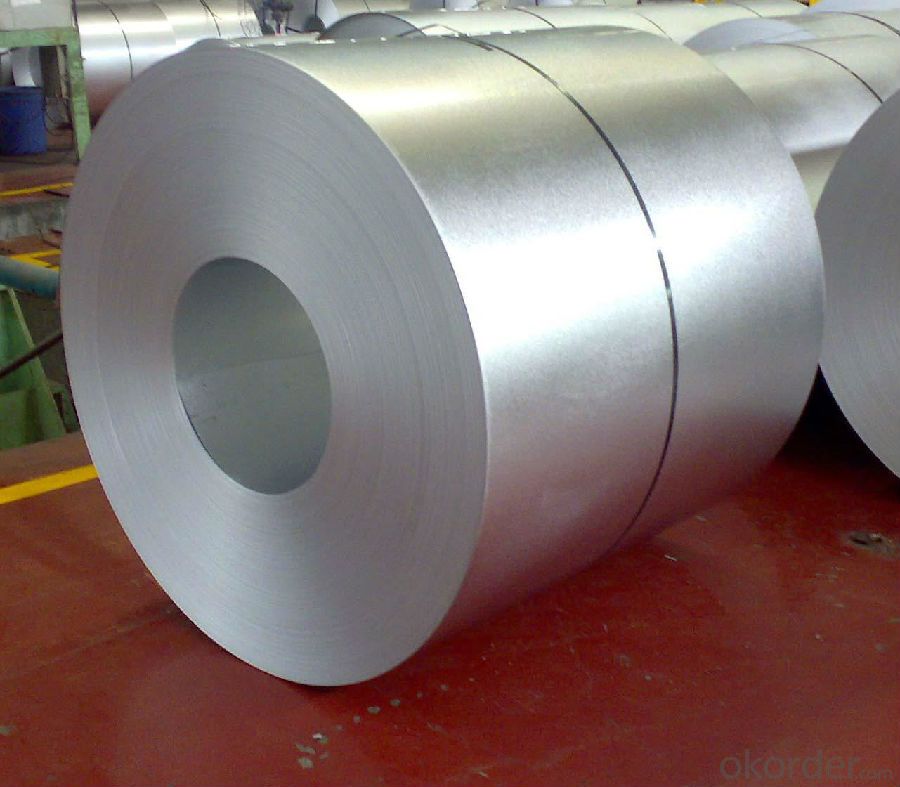

3. Aluzinc Steel Coil Images:

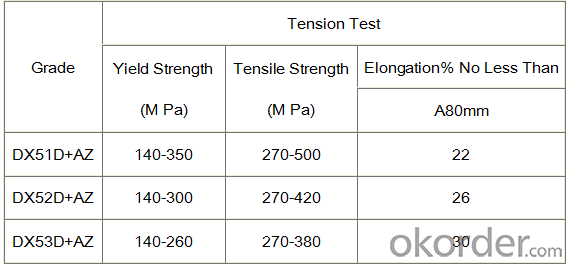

4.Aluzinc Steel Coil Specification

Thickness: 0.3-0.7mm

Width: 914-1250mm

Inner Diameter: 508-610mm

Weight of Steel Coil: 3-15MT

Coating Type: Al-Zn Alloy

Available Dipped Layer: 50-150g/m2

Surface Finish Structure: Normal Spangle & Small Spangle & Zero Spangle

Available Surface Treatment: Passivating & Oiling & AFP & Filming

5.FAQ of Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Iron too heavy for Ulysses but if there was any iron used id imagine it was steel. Can steel go deeper into sun than iron? Compare two bolts.. 1steel 1iron..is there a difference to what the steel can do?

- Steel is usually stronger than iron. But steel is, by definition, an alloy of iron and one or more other materials. There are thousands of different steel alloys. Be more specific.

- Q: How are steel coils used in the manufacturing of engine mounts?

- Steel coils are commonly used in the manufacturing of engine mounts to provide durability, strength, and flexibility. These coils are typically designed to absorb and dampen vibrations, shocks, and movements generated by the engine during its operation. By integrating steel coils into the engine mount design, manufacturers can ensure better stability, improved performance, and reduced noise levels in vehicles.

- Q: What are the factors driving the growth of the steel coil industry?

- There are several factors driving the growth of the steel coil industry. Firstly, the increasing demand for steel coils in various sectors such as automotive, construction, and manufacturing is a significant driver. Additionally, the expanding infrastructure projects and urbanization in emerging economies contribute to the growth of the industry. Moreover, technological advancements in steel manufacturing processes and the adoption of efficient production techniques also play a crucial role in driving the growth of the steel coil industry.

- Q: What are the different types of steel alloys used in coil manufacturing?

- There are several different types of steel alloys used in coil manufacturing, including carbon steel, stainless steel, and high-strength low-alloy (HSLA) steel. Carbon steel is the most commonly used alloy, known for its high strength and durability. Stainless steel is used for its corrosion resistance and aesthetic appeal. HSLA steel offers a combination of strength, formability, and weldability, making it suitable for various applications in coil manufacturing.

- Q: What is the average shelf life of a painted steel coil?

- The average shelf life of a painted steel coil can vary depending on various factors such as the quality of the paint, environmental conditions, and storage methods. However, on average, a well-maintained painted steel coil can have a shelf life of 10 to 20 years.

- Q: and is that different from the components of steel

- Making steel is very energy intensive. Mining the raw ore requires a lot of machinery that uses fuel or electricity . Transporting the ore requires a lot of fuel. Refining not only uses a lot of electricity but coal is added to change the iron ore into steel.

- Q: I bought a stainless steel mood ring two days ago, but would it rust?Thanks in advance!

- Stainless steel can rust if placed in contact with some chemicals lik hypoclorite, bleach, or salt water. It depends on the type of stainless steel because there is not just a single stainless steel but a family of steel with different properties and corrosion resistance.

- Q: Ive been playing with my ping i3 graphite irons for 6 years now and some days i can hit it and some days i cant. Then i tried out my friends irons the other day and he had steel and i was hitting the ball anywhere i wanted it to go..Is that a fluke or is steel irons just better than shaft? I was thinking about trading my graphites for steel, is that a good idea??

- Ping Graphite Iron Shafts

- Q: I have a knife with 154cm steel on it and I always here that you should put oil on it to keep it from rusting but I am just wondering what kind of oil? And how do I apply it and do I just leave it on there?

- There are several grades of steel and other types of metals used in knives. Like another user said, if it is something like 420 Stainless Steel (a very common knife steel grade), then you should not have to worry about it rusting. I still apply oil to my stainless steel knives though to keep the action smooth. Non-stainless will require oil to prevent rust if you are planning on using them heavily. There is a such thing as knife oil and you can find it online. A lot of car or sportting lubricants will work though. I use Rem Oil, a popular gun oil that you can find at Wally World for about $3 a can. Disassemble your knife. Use a solvent and a cleaning solution to clean off the old oil, dirt, and gunk. I use Hoppes solvent (a solvent that can be found at Wal-Mart for a few bucks) and either pour it into a small shot-glass and dip a toothbrush in it, dampen a wash-rag with it, or pour some in the cap and dab a cotton swab on it. Using one of these tools, I swab down my knives completely, focusing mainly on moving parts and parts of the knife that experiences high abrasion (the lock of a liner lock knife for example). Then I spray it down with Rem Oil. Reassemble the knife and let it sit overnight. The next day, I'll rub off any excess oil from the grips. Usually though, the knife is ready to rock the moment I reassemble it. So that's cleaning knives in a nutshell: take it apart, clean off the old oil and dirt, re-oil it with gun oil, then put it back together.

- Q: Can steel coils be coated with magnetic materials?

- Yes, steel coils can be coated with magnetic materials. The coating process typically involves applying a thin layer of magnetic material, such as nickel or zinc, to the surface of the steel coils. This coating enhances the magnetic properties of the steel, making it more suitable for specific applications that require magnetism.

Send your message to us

Aluzinc Steel Sheet in Coil with Prime Quality and Lowest Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords