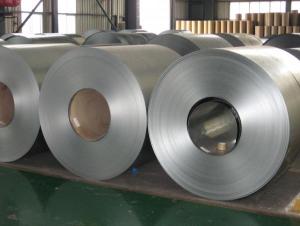

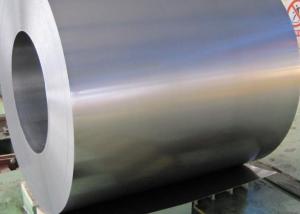

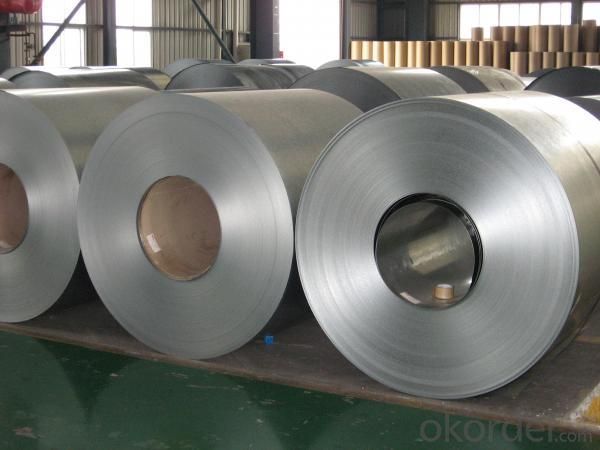

Aluzinc Coated Steel Coils

- Loading Port:

- China Main Port

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 25mt m.t.

- Supply Capability:

- 5000mt/per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information Of Galvalume Steel Coil AZ150

With Cold Rolled Steel as base metal,with the aluzinc coated, finally the plate steel is called galvalume steel. Galvalume steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

Thickness 0.23-1.2mm (BMT) |

Zinc Coating 80-275g/m2 |

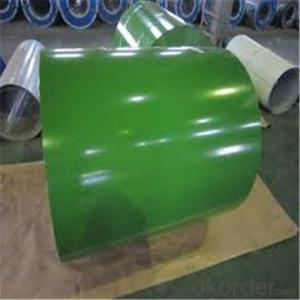

Color According to RAL color fan |

Internal Diameter 508mm or 610mm |

Coil Weight 4-8MT |

Quality Commercial and structural quality |

Paint Polyester paint for topside, epoxy for reverse |

Standard JIS G 3312, ASTM A755M, EN 10169 |

Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD, S280GD,S350GD,CS,FS,SS |

Chemical Composition Of Aluzinc Steel

C | Si | Mn | P |

0.04-0.06% | 0.01-0.03% | 0.18-0.22% | 0.014-0.016% |

Technical Data Of Prepainted Galvanized Steel

Yield Strength | (Mpa) 280-320 |

Tensile Strength | (Mpa) 340-390 |

Elongation | 20%-30% |

Reverse Impact | 9J |

T-bending | ≥2T |

Pencil Hardness | ≥2H |

Duration Of Salt Spray Test | 500 H |

Bending At 180 Degree | No crack, purling and fraction |

Application Of Aluzinc Steel

Outdoor:

roof, roof structure, surface sheet of balcony,

frame of window, door, door of garage, roller shutter door, booth, Persian blinds, cabana, etc.

In door:

door, isolater, frame of door, light steel structure of house, home electronic appliances, etc.

Packaging & Delivery Of Aluzinc Steel

Anti-damp paper inside full wrapped with plastic film, iron sheet outside on wooden pallet in 20 feet container with 25mt.

- Q: Brass as a rule I believe is betterhowever I do not plan to get into reloading any time soon I just want some cheap practice ammo so will steel case ammo hurt my gun (semi auto) any more than brass ammo and if so how much more?

- Depends what your gun is. I wouldn't shoot steel through a 5,000 dollar gun but my SKS jams up with anything except steel ammo. It adds wear to some guns but in most cases you won't shoot enough to cause any real problems. They also make steel that is coated in lacquer that protects your gun a little. In most cases steel is no big deal, in high performance weapons I would say no.

- Q: What are the quality standards for steel coil manufacturing?

- The quality standards for steel coil manufacturing typically include criteria such as dimensional accuracy, surface finish, mechanical properties, chemical composition, and adherence to industry-specific standards like ASTM or EN. These standards ensure that the steel coils meet the required specifications for various applications and provide reliable performance in terms of strength, durability, and consistency. Additionally, manufacturers often follow strict quality control processes throughout the production cycle to ensure the quality of the final product.

- Q: How long can steel coils be stored before they need to be used?

- Steel coils can typically be stored for an extended period of time, ranging from a few months to several years, depending on various factors such as the coating, storage conditions, and the type of steel. However, it is generally recommended to use or sell steel coils within a year or two to ensure their optimal quality and performance.

- Q: What are the limitations of using steel coils in certain applications?

- One limitation of using steel coils in certain applications is their susceptibility to corrosion. Steel coils can rust when exposed to moisture or harsh environments, which can affect their structural integrity and performance. Additionally, steel coils can be heavy and bulky, making them less suitable for applications that require lightweight materials or intricate designs. Finally, steel coils may not be suitable for applications that require specific electrical or thermal conductivity properties, as steel is not the most conductive material in these aspects.

- Q: What are the common methods of joining steel coils together?

- Common methods of joining steel coils together include welding, mechanical fastening (such as using bolts or screws), adhesive bonding, and interlocking methods.

- Q: Can steel coils be bent or shaped?

- Yes, steel coils can be bent or shaped due to their flexibility and malleability.

- Q: What are the dimensions of steel coils used in the mining equipment industry?

- The dimensions of steel coils utilized in the mining equipment sector may differ depending on the particular application and demands. Nevertheless, there are frequently employed standard dimensions. Typically, the width of steel coils used in the mining equipment industry can range from 600mm to over 2000mm. This allows for adaptability in the manufacturing process and guarantees that the coils can be customized to fit different equipment sizes and specifications. Regarding thickness, steel coils employed in mining equipment can range from 1.5mm to 20mm or more. The specific thickness is determined by factors such as equipment type, intended usage, and required durability level. The length of steel coils used in the mining equipment industry can also vary, but usually falls within the range of 1000mm to 6000mm. Once again, this offers flexibility in the manufacturing process and ensures that the coils can be cut to suit the exact requirements of the equipment being produced. It is essential to acknowledge that these dimensions are not fixed and can be tailored to meet the specific needs of the mining equipment sector. Manufacturers and suppliers in the industry can often provide coils in different sizes and dimensions to accommodate the wide array of equipment used in mining operations.

- Q: What are the common storage defects in steel coils?

- Common storage defects in steel coils include corrosion, rusting, surface damage (such as scratches or dents), coil slippage or misalignment, coil edge damage, and moisture or water damage. These defects can occur due to improper storage conditions, handling, or exposure to environmental factors. Regular inspection and proper storage practices are essential to prevent these defects and maintain the quality of steel coils.

- Q: Are Steel Building Kits really helpful while erecting a steel building?

- I put up a 30'x40' Mueller Steel Building from a bolt together kit 6 yrs ago. Fully insulated, 2 10'x10' roll up doors, 1 walk thru door, 3 windows, 2' overhang all around, and gutters. The building price minus the slab was about $9500. The only special equipment was a neighbor's large Farmall with a hay spike on the FEL that we used to lift the trusses in place. Then it was mainly cordless drills to put in LOTS of self tapping screws, circular saw with metal cutting blade, tall ladders, etc. Had help putting up the trusses and putting up the roof panels. Everything else I did by myself. Took about 6 wks, but that was only working weekends and maybe 3 evenings a week since that land is 30 miles from my house. Would have gone a lot faster with at least one helper.

- Q: steel of beam has been rusted ,how can i repair it?

- chrome steel is an alloy of iron and different metals, fairly Chromium and vanadium. you do no longer see it with the bare eye yet on the exterior of any chrome steel (SS) there are iron atoms and chromium atoms that are uncovered. in spite of the shown fact that, the chromium reacts preferentially to type an oxide. In essence, think of of chromium sacrificing itself for iron so as that iron won't rust. What a helpful guy huh! it somewhat is reported as passivation purely like maximum responders suggested. in spite of the shown fact that, greater desirable than that the chromium oxide varieties a good shielding layer that varieties a actual barrier combating Oxygen or any oxidant to realize and attack the iron below it. additionally, the chromium oxide shaped isn't FLAKY and porous, so it does not mar maximum of the exterior as an iron oxide (rust) would. For technology project, you won't make it too technical yet you additionally could make a reference or make an ANALOGY of rust prevention to intense college or social circumstances as being there to your pal or classmate yet in real existence, whilst the possibilities are too great, that secure practices afforded via chromium won't be adequate. because of the fact ultimately all steel uncovered to very oxidizing atmospheres will rust. in basic terms somewhat ruin in the exterior is sufficient to initiate the technique of rusting.

1. Manufacturer Overview

| Location | Wuxi, China |

| Year Established | 2002 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | Mid East Northern Europe North America Eastern Asia Africa Eastern Europe Southeast Asia Western Europe Southern Europe |

| Company Certifications | ISO 9001;ISO 14000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 50 |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 600,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Aluzinc Coated Steel Coils

- Loading Port:

- China Main Port

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 25mt m.t.

- Supply Capability:

- 5000mt/per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords