Aluzinc Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

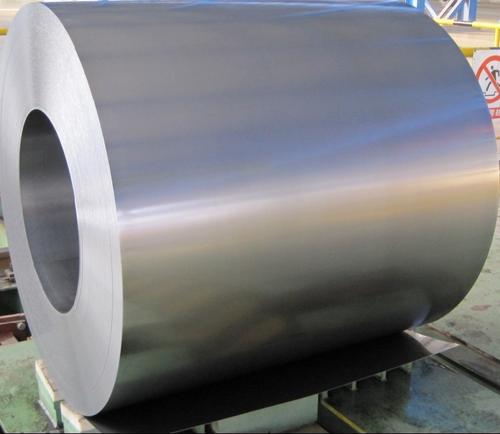

General Information Of Galvalume Steel Coil AZ150

With Cold Rolled Steel as base metal,with the aluzinc coated, finally the plate steel is called galvalume steel. Galvalume steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

Thickness 0.23-1.2mm (BMT) |

Zinc Coating 80-275g/m2 |

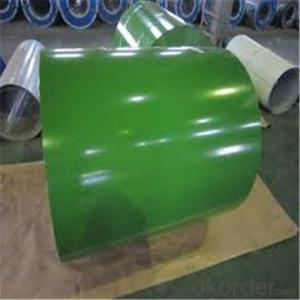

Color According to RAL color fan |

Internal Diameter 508mm or 610mm |

Coil Weight 4-8MT |

Quality Commercial and structural quality |

Paint Polyester paint for topside, epoxy for reverse |

Standard JIS G 3312, ASTM A755M, EN 10169 |

Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD, S280GD,S350GD,CS,FS,SS |

Chemical Composition Of Aluzinc Steel

C | Si | Mn | P |

0.04-0.06% | 0.01-0.03% | 0.18-0.22% | 0.014-0.016% |

Technical Data Of Prepainted Galvanized Steel

Yield Strength | (Mpa) 280-320 |

Tensile Strength | (Mpa) 340-390 |

Elongation | 20%-30% |

Reverse Impact | 9J |

T-bending | ≥2T |

Pencil Hardness | ≥2H |

Duration Of Salt Spray Test | 500 H |

Bending At 180 Degree | No crack, purling and fraction |

Application Of Aluzinc Steel

Outdoor:

roof, roof structure, surface sheet of balcony,

frame of window, door, door of garage, roller shutter door, booth, Persian blinds, cabana, etc.

In door:

door, isolater, frame of door, light steel structure of house, home electronic appliances, etc.

Packaging & Delivery Of Aluzinc Steel

Anti-damp paper inside full wrapped with plastic film, iron sheet outside on wooden pallet in 20 feet container with 25mt.

- Q: What are the quality control measures for steel coils?

- Quality control measures for steel coils typically include various inspections and tests to ensure that the coils meet the required standards and specifications. These measures often involve visual inspections to identify any surface defects or irregularities, such as cracks, dents, or scratches. Additionally, dimensional checks are performed to verify the coil's size, shape, and weight. Other quality control measures may involve conducting mechanical tests, such as tensile strength and hardness tests, to assess the strength and durability of the steel coils. Overall, these measures aim to guarantee that the steel coils are of high quality and suitable for their intended applications.

- Q: How do steel coils contribute to structural integrity in buildings?

- The role of steel coils in ensuring the structural integrity of buildings cannot be overstated. They play a vital role in multiple ways. To begin with, steel coils are extensively utilized in the construction industry to manufacture essential building components like beams, columns, and trusses. These components are responsible for providing support and stability to the overall structure. Due to their exceptional tensile strength and durability, steel coils guarantee that these components can withstand heavy loads and maintain their structural integrity over an extended period. This is particularly crucial in buildings with multiple floors or large open spaces, where the structural elements need to bear substantial weight without deforming or collapsing. Moreover, steel coils are also instrumental in reinforcing concrete structures. Reinforced concrete is a widely adopted construction technique, and steel coils, in the form of reinforcement bars or mesh, are embedded within the concrete to counteract tensile forces. While concrete excels at withstanding compressive forces, it is weak in tension. By incorporating steel coils, the composite material gains the ability to resist both compression and tension, thereby enhancing its structural integrity. This reinforcement technique is particularly vital in high-rise buildings or structures subject to seismic activity, where the risk of structural failure due to bending or cracking is heightened. Another significant contribution of steel coils to structural integrity lies in their corrosion resistance properties. Steel coils are often coated with protective layers, such as zinc through galvanization or paint, to prevent corrosion caused by moisture, chemicals, or environmental factors. Corrosion weakens the structural integrity of steel, leading to degradation and potential failure. By utilizing corrosion-resistant steel coils, the lifespan of the building is prolonged, and the risk of structural damage is significantly diminished. Furthermore, steel coils offer tremendous versatility in design and construction. Their flexibility and malleability allow for the creation of complex and intricate building structures, enabling architects and engineers to push the boundaries of design while maintaining structural integrity. Steel coils can be shaped, bent, and welded into various forms, making them an ideal material for constructing innovative and aesthetically pleasing buildings. In conclusion, steel coils are indispensable in ensuring the structural integrity of buildings. Their strength, stability, durability, corrosion resistance, and design versatility make them an essential material in modern construction, guaranteeing the safety and longevity of buildings for years to come.

- Q: What are the common surface defects found in steel coils?

- There are several common surface defects that can be found in steel coils. One of the most common defects is rust or corrosion. This occurs when moisture comes into contact with the steel surface, causing it to oxidize and form rust. Another common defect is scratches or abrasions, which can occur during the handling or transportation of the coils. These can range from minor surface scratches to deeper gouges that can affect the structural integrity of the steel. In addition, there can be surface roughness or unevenness, which can be caused by improper rolling or cooling processes during manufacturing. This can result in an inconsistent surface texture that may impact the appearance and performance of the steel. Another defect is scale, which is a layer of oxide that forms on the surface of the steel during the manufacturing process. This can give the steel a rough and uneven appearance. Finally, there can be oil or grease stains on the surface of the steel, which can occur during the manufacturing or handling process. These stains can affect the adhesion of paints or coatings applied to the steel. Overall, these common surface defects in steel coils can impact the quality, appearance, and performance of the steel, and may require remedial actions such as cleaning, grinding, or recoating to resolve.

- Q: What kind of steel should be used for constructing a steel building?

- Please specify what kind of steel, is it structural steel (like wide flange, channel or Z-section) or reinforcing steel? For structural steel, all steel members that passed the requirement of ASTM-A360 are the best quality. While for reinforcing steel, it should passed the requirement of ASTM-D3963 for epoxy coated and ASTM-A615 (Grade 60) for deformed bars.

- Q: and which one is better?i'm looking into buying some aftermarket headers, but companies make them in both chrome and stainless steel

- Chrome looks better, but it will eventually rust if it's exposed to enough moisture. Stainless steel will not rust. I would spend the extra money and get the stainless headers.

- Q: How are steel coils used in the production of metal panels?

- Steel coils are an essential component in the production of metal panels. These coils, which are typically made from high-quality steel, serve as the raw material for manufacturing various types of metal panels. To begin the production process, the steel coils are first unrolled and flattened using specialized machinery. This allows for a consistent and uniform thickness throughout the sheet. The flattened steel is then cut into the desired length and width, depending on the specific requirements of the metal panel being produced. Once the steel has been cut, it undergoes further processing, such as cleaning and coating. This is done to remove any impurities and protect the steel from corrosion or damage. The coating also enhances the appearance of the metal panel and provides additional durability and longevity. After the cleaning and coating process, the steel sheets are formed into the desired shape using various techniques, such as roll forming or stamping. This allows for the creation of different types of metal panels, including roofing panels, wall panels, and decorative panels, among others. The steel coils used in the production of metal panels are chosen for their strength, durability, and versatility. Steel is known for its excellent structural properties, making it an ideal material for constructing sturdy and long-lasting metal panels. Additionally, steel is highly resistant to environmental factors, such as extreme weather conditions, which further enhances the durability of the metal panels. In conclusion, steel coils play a crucial role in the production of metal panels. They serve as the raw material for manufacturing these panels and undergo various processes to ensure their quality and durability. The use of steel coils allows for the production of a wide range of metal panels that can be used in various industries and applications.

- Q: How are steel coils used in the manufacturing of construction excavators?

- Steel coils are used in the manufacturing of construction excavators as they are the primary material for constructing the structural components, such as the boom, arm, and bucket. These coils are processed into various shapes and sizes through cutting, bending, and welding techniques, and then assembled to create the sturdy and durable framework of the excavator.

- Q: How do steel coil manufacturers ensure timely delivery?

- Timely delivery is ensured by steel coil manufacturers through a variety of strategies and measures. Their first priority is to maintain a well-coordinated system for production and supply chain management. This involves efficiently scheduling production processes, monitoring inventory levels, and closely coordinating with raw material suppliers. In addition, advanced forecasting techniques are often employed by steel coil manufacturers to predict product demand. By analyzing historical data, market trends, and customer behavior, they can anticipate future orders and plan production accordingly. This proactive approach minimizes the risk of delays and allows for better allocation of resources. Furthermore, close collaboration with transportation and logistics companies is essential to ensure smooth and timely delivery. Strategic partnerships are established and favorable agreements negotiated to facilitate efficient transportation of steel coils to customers. This includes optimizing routes, utilizing reliable carriers, and closely tracking shipments to promptly address any unforeseen issues. Moreover, buffer stocks may be maintained by manufacturers to mitigate the impact of unexpected disruptions, such as equipment failures or supplier delays. By having a safety stock of finished products, they can quickly respond to urgent orders and uphold their delivery commitments. Lastly, effective communication plays a crucial role in ensuring timely delivery. Steel coil manufacturers maintain open lines of communication with their customers, keeping them informed about production progress and potential delays. This transparency allows for proactive problem-solving and helps manage customer expectations. In conclusion, steel coil manufacturers employ efficient production and supply chain management systems, advanced forecasting techniques, collaboration with transportation and logistics companies, buffer stocks, and effective communication to ensure timely delivery. These strategies collectively enable them to meet delivery deadlines and provide reliable service to their customers.

- Q: hello, I am trying to figure out what wok to get and came across a website that offers many woks out of different materials. what is the best, or considered original (traditional)? I have a couple of cast iron pots and pans - too heavy, so I am assuming it will take some time for a cast iron wok to heat up. what about carbon steel and stainless steel? Thanks

- Traditionally woks do take a long to heat up but the trick is that they hold the heat for a long time, so either stainless steel for convenience or cast iron for tradition. Don't use anything non stick, chinese cooking uses a lot of oil, the non-stick will just be unhealthy when it starts to burn off. The cast iron will be good because it'll heat up and keep its heat, in chinese homes that have the wok, the wok usually gets heated up throughout a few hours, you need it to be really hot all the way through all over the pan to do chinese cooking. also traditionally woks are built into home or are big and positiioned over a fire not to be moved too much, the point is to keep stiring and stiring and stiring until your food is cooked.

- Q: What are the common maintenance practices for steel coils?

- Common maintenance practices for steel coils include regularly inspecting for any signs of corrosion, cleaning the coils to remove dirt and debris, applying protective coatings or paint to prevent rust, storing the coils in a dry and well-ventilated area, and ensuring proper handling and transportation to avoid any damage. Additionally, it is important to monitor and control the humidity levels around the coils to prevent moisture buildup, which can lead to corrosion.

Send your message to us

Aluzinc Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords