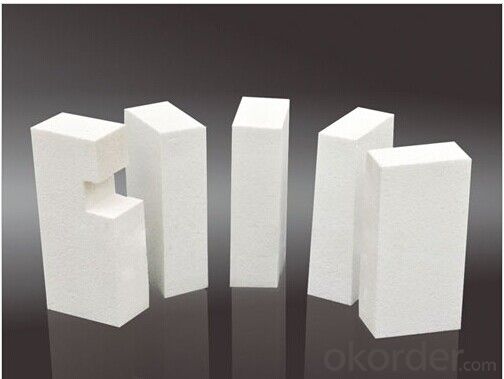

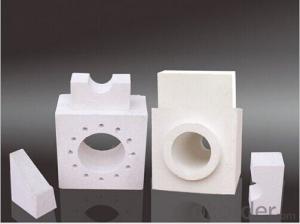

Alumuna Hollow Ball Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1. High temperature resistance.

2. Good thermal insulation.

3. Professional manufacturer.

Alumina hollow ball brick, Alumina bubble brick , Alumina hollow sphere brick , Hollow alumina sphere bricks

Alumina hollow ball brick used the alumina hollow ball,corundum powder,and calcined powders mixed at definite proportion as raw material. After mixing, drying, forming, firing at high temperature shuttle kiln made.

Physical and chemical index:

Item | ZYL-84 | ZYL-90 | ZYA-1.2 | ZYA-1.5 | ZYA-1.7 |

Al2O3 % ≥ | 84 | 90 | 98.5 | 98.5 | 98.5 |

Fe2O3 % ≤ | 0.8 | 0.5 | 0.3 | 0.3 | 0.3 |

SiO2 % ≤ | 15 | 9 | 1.0 | 1.0 | 1.0 |

Bulk density, g/m3,≤ | 1.5 | 1.5 | 1.2 | 1.5 | 1.7 |

Porosity,%, ≥ | 58 | 60 | 62 | 60 | 58 |

CCS,Mpa, ≥ | 16 | 15 | 3 | 12 | 15 |

Thermal conductivity, 1000°C,( W/m.k )≤ | 1.2 | 1.15 | 0.95 | 1.05 | 1.15 |

0.1Mpa RUL,°C ≥ | 1650 | 1700 | 1700 | 1700 | 1700 |

Refractoriness,°C ≥ | 1800 | 1800 | 1800 | 1800 | 1800 |

Characteristic:

1. High temperature resistance.

2. Low thermal conductivity.

3. Good thermal insulation.

4. High strength.

5. Can direct contact with flame.

6. Good chemical stability (acid-base erosion resistance ).

7. Low bulk density (lighter than the same kind of material ,thin kiln wall, low cost ) .

- Q: Can insulating fire bricks be used for insulation in sewage treatment plants?

- Yes, insulating fire bricks can be used for insulation in sewage treatment plants. These bricks are designed to withstand high temperatures and provide excellent thermal insulation. They can be used to line the walls, floors, and ceilings of sewage treatment plants to reduce heat loss and improve energy efficiency. Additionally, insulating fire bricks have good resistance to chemicals and moisture, making them ideal for use in environments with high levels of humidity and corrosive substances found in sewage treatment plants.

- Q: How do insulating fire bricks help improve the efficiency of heat treatment processes?

- Insulating fire bricks help improve the efficiency of heat treatment processes by effectively reducing heat loss. Due to their low thermal conductivity, these bricks act as a barrier, preventing heat from escaping and maintaining high temperatures for longer periods. This allows the heat treatment process to be more energy-efficient, as less energy is required to achieve and maintain the desired temperatures. Additionally, insulating fire bricks help to evenly distribute heat, resulting in more consistent and uniform heat treatment outcomes.

- Q: Are insulating fire bricks resistant to fluorine gas?

- Yes, insulating fire bricks are generally resistant to fluorine gas due to their refractory properties and ability to withstand high temperatures and chemical corrosion.

- Q: Are insulating fire bricks porous?

- Yes, insulating fire bricks are porous. Porosity is a characteristic of insulating fire bricks that allows them to have low thermal conductivity. These bricks are made from ceramic materials and contain a high percentage of tiny air pockets or voids, which trap and slow down the transfer of heat. This porosity also makes the bricks lightweight and resistant to thermal shock. The ability of the insulating fire bricks to retain heat and provide effective insulation is directly linked to their porous structure.

- Q: Is it possible to recycle used insulating fire bricks?

- Yes, it is possible to recycle used insulating fire bricks. These bricks can be crushed, ground, or shredded, and then the resulting material can be used as a raw material in the production of new bricks or as an aggregate in construction materials. Recycling used insulating fire bricks helps to reduce waste and conserve resources.

- Q: Can insulating fire bricks be used for fireplace construction?

- Yes, insulating fire bricks can be used for fireplace construction. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for lining the inside of fireplaces to retain heat and improve energy efficiency.

- Q: Can insulating fire bricks be used in brick kilns?

- Yes, insulating fire bricks can be used in brick kilns. They are specifically designed to withstand high temperatures and provide excellent insulation, making them suitable for use in brick kilns where heat retention is crucial.

- Q: Are insulating fire bricks suitable for use in carbon black furnaces?

- Insulating fire bricks, made from refractory materials with excellent insulation properties, are well-suited for carbon black furnaces. These furnaces, operating at temperatures exceeding 1,000 degrees Celsius, benefit from the use of insulating fire bricks by reducing heat loss and improving energy efficiency. The bricks' thermal shock resistance is crucial for the cyclic heating and cooling within the furnace. Furthermore, their low thermal conductivity helps maintain a stable temperature inside the furnace and prevents excessive heat loss. In conclusion, insulating fire bricks provide a dependable and efficient lining option for carbon black furnaces.

- Q: Can insulating fire bricks be used in blast furnaces?

- Yes, insulating fire bricks can be used in blast furnaces. Insulating fire bricks are designed to withstand high temperatures and provide excellent thermal insulation. Blast furnaces operate at extremely high temperatures, typically around 1500°C (2732°F), and require materials that can withstand these harsh conditions. Insulating fire bricks are made from lightweight materials such as ceramic fibers, which have low thermal conductivity and can effectively retain heat. This makes them ideal for lining the walls and roofs of blast furnaces, as they help to conserve energy, reduce heat loss, and improve overall furnace efficiency. Additionally, insulating fire bricks can also help to protect the structural integrity of the blast furnace by reducing thermal stress and preventing excessive heat transfer to the surrounding environment. Overall, the use of insulating fire bricks in blast furnaces can contribute to improved performance, energy savings, and extended furnace life.

- Q: Can insulating fire bricks be used in high-temperature ducts?

- Insulating fire bricks can indeed be used in high-temperature ducts. These bricks are specially designed to withstand extreme temperatures, making them an ideal choice for applications where heat retention and insulation are crucial. With their low thermal conductivity and high resistance to thermal shock, insulating fire bricks can effectively trap heat within the ducts, preventing any loss of energy and ensuring efficient heat transfer. Additionally, their lightweight nature makes them easy to install and handle, while their durability allows them to withstand the harsh conditions of high-temperature environments. Overall, insulating fire bricks are a reliable and effective solution for insulating high-temperature ducts.

Send your message to us

Alumuna Hollow Ball Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords