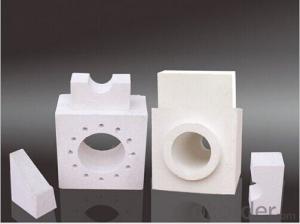

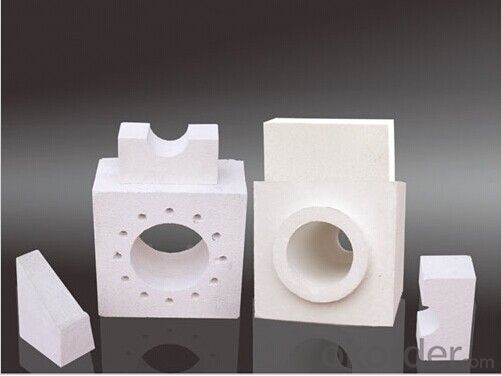

High-Aluminum Low-Iron Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

High aluminum refractory brick belongs to gender refractory materials with its thermal stability.

Feature:

1.bricks are made from high quality bauxite

2.dry pressed

3.burned under tunnel kiln

4.accurate dimension

5.high strength

Product specification: Can be used in various kilns because of its cheapness and general tray package. Among all of the refractory materials, it is the mostly used in the key positions.Molding method: it has down draft kiln and tunnel kiln and the general sintering temperature is 1360-1480 degrees. It is a kind of aluminosilicate refractory product which aluminum oxide (Al2O3) content is higher than 48%.

Item | Properties | |||||

LZ-80 | LZ-75 | LZ-65 | LZ-55 | LZ-48 | ||

Al2O3 ,% | 80 | ≥75 | ≥65 | ≥55 | ≥48 | |

Refractoriness °C | ≥1790 | ≥1790 | ≥1790 | ≥1770 | ≥1750 | |

Bulk density,g/cm3 | 2.65 | 2.5 | 2.45 | 2.4 | 2.3 | |

Softening temperature under load | 1530 | ≥1520 | ≥1500 | ≥1470 | ≥1420 | |

Permanent linear change,% | 1500°CX2H | +0.1 -0.4 | +0.1 -0.4 | +0.1 -0.4 | +0.1 -0.4 |

|

1450°CX2H |

|

|

|

| +0.1 -0.4 | |

Apparent porosity,% | 22 | ≤23 | ≤23 | ≤22 | ≤22 | |

Cold Crushing strength Mpa | 55 | ≥50 | ≥45 | ≥40 | ≥35 | |

Application | All industrial furnace | |||||

- Q: Can insulating fire bricks be used in metal smelting furnaces?

- Insulating fire bricks are indeed suitable for metal smelting furnaces. Specifically designed with low thermal conductivity, these bricks effectively retain heat and prevent heat loss from the furnace. This quality makes them perfect for maintaining high temperatures over long periods in metal smelting furnaces. Moreover, insulating fire bricks exhibit resistance to thermal shock, enabling them to endure the extreme conditions and sudden temperature fluctuations that occur during metal smelting processes. Additionally, their lightweight nature facilitates easy handling and installation within the furnace. In summary, insulating fire bricks are an excellent choice for enhancing energy efficiency and extending the lifespan of metal smelting furnaces.

- Q: What is the porosity of insulating fire bricks?

- Insulating fire bricks possess a porosity that pertains to the quantity of vacant areas or gaps present in the material. These bricks are engineered to possess a considerable porosity, typically falling within the range of 50% to 80%. This notable porosity facilitates exceptional thermal insulation properties by entraping air or other insulating gases within the gaps. The air pockets function as obstacles for heat transfer, thereby diminishing the conduction of thermal energy through the bricks. Consequently, insulating fire bricks prove highly efficient in upholding elevated temperatures within industrial furnaces, kilns, or other high-temperature uses while minimizing heat loss. The specific porosity of insulating fire bricks can differ based on the manufacturing process and the desired level of insulation necessitated for a specific application.

- Q: Are insulating fire bricks resistant to metal penetration?

- Insulating fire bricks are generally resistant to metal penetration. These bricks are made from refractory materials, which have high melting points and are designed to withstand high temperatures. They are often used in applications where they are exposed to extreme heat, such as in furnaces and kilns. Insulating fire bricks have low thermal conductivity, meaning they are good at preventing heat transfer. This property helps to keep the outer surface of the bricks cool, even when the interior is exposed to intense heat. As a result, these bricks can resist the penetration of molten metal. However, it is important to note that the resistance of insulating fire bricks to metal penetration can vary depending on the specific composition and quality of the bricks. Some lower-grade bricks may not provide the same level of resistance as higher-quality ones. Additionally, the duration and intensity of the heat exposure can also affect the bricks' resistance. In conclusion, while insulating fire bricks are generally resistant to metal penetration, it is crucial to consider the specific characteristics and quality of the bricks being used, as well as the conditions in which they are exposed to heat.

- Q: What is mullite insulation brick?

- Main features of mullite insulating bricks:1., green environmental protection, non-toxic, non corrosive, safe to use.2. 、 good adaptability with cement.3., light insulation brick with foam mechanism bubble, can get foam uniform bubble diameter.4. excellent foaming performance, foaming multiples of more than thirty times.

- Q: Are insulating fire bricks suitable for use in oil refineries?

- Yes, insulating fire bricks are suitable for use in oil refineries. They possess excellent thermal insulation properties, high resistance to thermal shock, and can withstand high temperatures. These qualities make them ideal for lining furnaces, boilers, and other equipment used in the refining process, helping to conserve energy and maintain stable operating conditions.

- Q: Can insulating fire bricks be used in pottery kilns?

- Pottery kilns can indeed utilize insulating fire bricks. These bricks, also referred to as refractory bricks, possess a specialized design that enables them to endure high temperatures and provide insulation to retain heat within the kilns. Alumina, silica, and other refractory materials are employed in the creation of these bricks, as they possess exceptional thermal resistance properties. The utilization of insulating fire bricks in pottery kilns aids in the maintenance of a consistent temperature, reduction of heat loss, and ensures efficient firing of clay and glazes. Moreover, these bricks contribute to the elongation of the kiln's lifespan by safeguarding the interior walls from extreme temperatures. Consequently, insulating fire bricks represent an ideal choice for pottery kilns and are extensively employed in the pottery industry.

- Q: What is the water absorption of insulating fire bricks?

- The water absorption of insulating fire bricks is typically low, ranging from 5% to 10%.

- Q: Can insulating fire bricks be used in combination with other insulation materials?

- Yes, insulating fire bricks can be used in combination with other insulation materials. Insulating fire bricks are known for their excellent thermal insulation properties and can be used to effectively reduce heat transfer in various applications such as kilns, furnaces, and fireplaces. However, in some cases, additional insulation may be required to achieve optimal thermal efficiency. Combining insulating fire bricks with other insulation materials can further enhance the overall insulation performance. For example, ceramic fiber blankets or boards can be used alongside insulating fire bricks to provide additional insulation and to fill any gaps or joints between the bricks. This combination can help minimize heat loss and improve energy efficiency. Furthermore, using multiple insulation materials can also provide other benefits such as increased fire resistance, improved sound insulation, and enhanced structural integrity. By utilizing different insulation materials in combination, it is possible to create a more effective insulation system that meets specific requirements for different applications. It is important to consider the compatibility and compatibility of the different insulation materials when combining them. Each material may have different thermal properties, density, and installation requirements, so it is crucial to follow the manufacturer's recommendations and guidelines for proper installation. In summary, insulating fire bricks can be used in combination with other insulation materials to enhance thermal insulation and improve overall performance in various applications. However, it is essential to ensure compatibility and follow proper installation guidelines for optimal results.

- Q: Are insulating fire bricks resistant to vermin infestation?

- Yes, insulating fire bricks are typically resistant to vermin infestation. These bricks are made from materials such as ceramic fibers, which do not provide a suitable environment for pests to inhabit or cause damage. Additionally, their dense composition and high-temperature resistance make it difficult for vermin to penetrate or chew through them.

- Q: Are insulating fire bricks suitable for use in the construction of drying ovens?

- Insulating fire bricks are indeed suitable for use in the construction of drying ovens. Their design aims to minimize thermal conductivity, enabling efficient heat retention within the oven. This particular feature is crucial for drying ovens as it promotes consistent and uniform temperature maintenance throughout the drying process. Moreover, insulating fire bricks possess remarkable resistance to thermal shock, ensuring they can endure rapid temperature changes that may occur during the oven's heating and cooling cycles. This durability guarantees that the bricks will not crack or break under extreme temperature conditions. Additionally, these bricks are lightweight and easy to handle, providing convenience during installation in drying ovens. Overall, their excellent insulation and thermal stability qualities make them a highly appropriate option for constructing drying ovens.

Send your message to us

High-Aluminum Low-Iron Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords