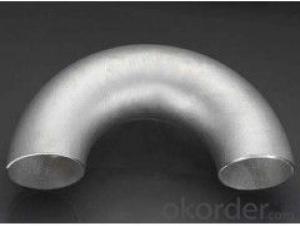

Aluminum Structural Profiles - Aluminum Elbow Profile 60 Degree

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

60 degree aluminum elbow

1.size:1/2"-48"

2.standard:ASTM B16.9

3.Certification: ISO

Type | 60 degree elbow |

Size | 1/2"-48"DN15--DN1200 |

Wall Thickness | Sch5--Sch160XXS |

Standard | ISO, SNSI, JIS, DIN, GB/T12459GB/T13401ASME B16.9SH3408 SH3409HG/T21635HG/T21631SY/T05010 |

Material | 20#/Q235 |

Packaging | wooden cases or wooden pallet or as per customers requirement |

Applications Range | petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc |

Min Order Quantity | According to customer's requirement |

Delivery Time | According to customer's requirement |

Quality | First grade |

Productivity | 8000000T/Y |

Others | 1.Special design available according to requirement 2.Anti-corrosion and high-temperature resistant with black painting 3. All the production process are made under the ISO9001:2008 strictly. |

- Q: This question seeks to understand the various types of aluminum profiles that are specifically utilized in the construction of railings and fences.

- <p>Aluminum profiles for railings and fences come in various types, each designed for specific applications and aesthetic preferences. Common types include: 1) Rectangular profiles, which are versatile for both commercial and residential settings; 2) Square profiles, offering a modern look and are often used in minimalist designs; 3) Round profiles, providing a classic appearance suitable for traditional or vintage styles; 4) Slotted profiles, which allow for easy assembly and are popular for their adjustability; 5) Hollow profiles, known for their strength and lightness, ideal for high-load applications; 6) Angled profiles, used to create corners and intersections in railing and fence designs. Each type can be further customized in terms of size, thickness, and finish to meet specific project requirements.</p>

- Q: Can aluminum profiles cross Luo? Why is the appearance of an aluminum profile component of a Japanese original machine extremely close to that of Luo Luo? Why? Why?

- Companies adhere to the "quality first, reputation first, service first" purpose, the spirit of innovation and sincere and trustworthy manner, first-class products, first-class brand, first-class performance is our consistent pursuit, we sincerely welcome domestic and foreign merchants to visit the company and guide.

- Q: This question asks for a list of various types of coatings applied to aluminum profiles to prevent corrosion.

- <p>Aluminum profiles are protected from corrosion through several types of coatings. These include: Anodizing, which forms a protective oxide layer; Powder Coating, a durable and weather-resistant finish; Electrophoretic Deposition (E-coat), offering a smooth, corrosion-resistant surface; Fluoropolymer coatings, known for their exceptional chemical resistance and UV stability; and Thermal Spray Coatings, which provide a hard, wear-resistant surface. Each method serves to enhance the aluminum's resistance to environmental factors and extend its lifespan.</p>

- Q: Is it possible to use aluminum profiles as a material for exterior walls or facades?

- <p>Yes, aluminum profiles can be used for exterior cladding or siding. They are known for their durability, low maintenance, and resistance to weather and corrosion, making them ideal for exterior applications. Aluminum profiles are lightweight, easy to install, and can be painted or finished in various ways to match architectural designs. They also offer excellent thermal performance and can be recycled, contributing to sustainability.</p>

- Q: This question asks for methods to avoid corrosion on aluminum profiles during the installation process.

- <p>To prevent corrosion on aluminum profiles during installation, follow these steps: Use high-quality aluminum that has a protective oxide layer. Ensure the installation environment is dry and clean. Avoid contact with corrosive substances like acids or alkalis. Apply a protective coating or sealant if the profiles will be exposed to harsh environments. Use stainless steel or corrosion-resistant fasteners. Regularly inspect and clean the profiles to remove any dirt or debris that could lead to corrosion. Proper installation techniques and maintenance can significantly reduce the risk of corrosion on aluminum profiles.</p>

- Q: Can aluminum profiles be used in the construction of retail displays?

- Yes, retail displays can utilize aluminum profiles in their construction. Aluminum is a versatile and lightweight material that finds common application in various industries, such as construction and retail. It provides several benefits for retail displays, including durability, resistance to corrosion, and ease of customization. Aluminum profiles can be effortlessly shaped and fabricated to create diverse types of retail displays like shelving units, display stands, signage frames, and product showcases. These profiles can be extruded into different shapes and sizes, enabling flexibility in design and functionality. Moreover, aluminum profiles can undergo various surface treatments, such as anodizing or powder coating, to enhance their appearance and offer a protective layer against scratches and wear. This ensures that retail displays can maintain their aesthetic appeal and withstand the demands of a retail setting. Furthermore, aluminum is an eco-friendly material due to its high recyclability, making it an environmentally conscious choice for retail displays. It can be easily recycled without losing its properties, thus reducing the environmental impact of the construction and retail industries. To summarize, aluminum profiles are a practical and appropriate option for constructing retail displays. They provide durability, versatility, and customization possibilities while being lightweight and environmentally friendly.

- Q: This question asks about the various surface treatments or finishes that can be applied to aluminum extrusions, which are shaped profiles made from aluminum.

- <p>Aluminum extrusions can be finished in several ways to enhance their appearance, durability, or functionality. Common finishes include anodizing, which provides a protective oxide layer; powder coating, offering a wide range of colors and textures; painting, which can be done electrostatically or by hand; polishing, resulting in a shiny, smooth surface; brushing, which creates a satin-like finish; and chromate conversion coating, which is a pretreatment for further painting or coating. Other finishes include wood grain transfer, which gives an aluminum surface a wood-like appearance, and various types of protective films or laminates. Each finish serves different purposes, from improving aesthetics to increasing corrosion resistance.</p>

- Q: Can aluminum profiles be used in warehouse and storage systems?

- Warehouse and storage systems can utilize aluminum profiles. These profiles possess qualities such as being lightweight, durable, and resistant to corrosion, which make them suitable for a variety of applications in warehouses and storage systems. They can be utilized for the construction of shelving units, racks, and partitions in order to optimize storage space and arrange inventory. Aluminum profiles are also highly versatile, allowing for easy customization and assembly to fulfill specific storage requirements. Furthermore, these profiles offer an exceptional strength-to-weight ratio, enabling them to support heavy loads without compromising the structural integrity. Overall, due to their durability, flexibility, and cost-effectiveness, aluminum profiles are widely preferred in warehouse and storage systems.

- Q: Are aluminum profiles suitable for use in mining and construction equipment?

- Yes, aluminum profiles are suitable for use in mining and construction equipment. Aluminum is a lightweight and durable material that offers excellent corrosion resistance, making it ideal for heavy-duty applications in these industries. Additionally, aluminum profiles can be easily customized and fabricated to meet specific design requirements, enhancing their suitability for use in mining and construction equipment.

- Q: Can aluminum profiles be used for stage and event structures?

- Yes, aluminum profiles can be used for stage and event structures. Aluminum is a lightweight and durable material that is commonly used in the construction industry for various applications, including stage and event structures. Aluminum profiles are versatile and can be easily shaped, cut, and joined together to create custom structures. They offer excellent strength-to-weight ratio, making them suitable for supporting heavy equipment and ensuring the safety of performers and audience members. Additionally, aluminum profiles can be powder-coated or anodized to provide a decorative finish and protect them from corrosion, enhancing the visual appeal and longevity of the structures. Overall, aluminum profiles are a popular choice for stage and event structures due to their versatility, strength, and aesthetic qualities.

Send your message to us

Aluminum Structural Profiles - Aluminum Elbow Profile 60 Degree

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords