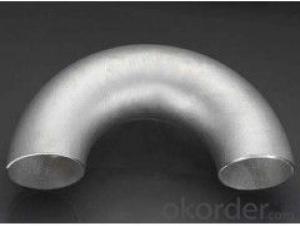

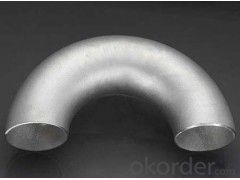

60 Degree Aluminum Tile Trim Profiles Elbow for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

60 degree aluminum elbow:

Material : carbon steel , stainless steel and alloy steel,

60 degree aluminum elbow

Specifications

ASTM B16.9 A234 WPB 90degree 1.5D carbon steel elbow

1.A234 WPB elbow

2.size:1/2"-72"

3.material:A234 WPB

4.API CE ISO

ASTM B16.9 A234 WPB 90degree 1.5D carbon steel elbow

1.A234 WPB elbow

2.size:1/2"-72"

3.material:A234 WPB

4.API CE ISO

Size | 1/2''-24 seamless elbow 26''-72''butt weld elbow |

Wall Thickness | SCH10-SCH160,STD,XS,XXS, GOST , DIN, JIS standard thickness |

Standard | ASTMA234,ASTM A420,ANSI B16.9/B16.28/B16.25,ASME B16.9, JIS B2311-1997/2312, JIS B2311/B2312, DIN 2605-1/2617/2615, GB 12459—99,GOST,EN Standard etc. |

Material | Q235, 20#, 10#, Q345 A234 WPB, WP5, WP9,WP11, ST37.0,ST35.8,ST37.2,ST35.4/8,ST42,ST45,ST52,ST52.4 STP G38,STP G42,STPT42,STB42,STS42,STPT49,STS49 |

Application | Low and middle pressure fluid pipeline,boiler, petroleum and natural gas industry,drilling,chemical industry, electric industry,shipbuilding, fertilizer equipment and pipeline, structure,petrochemical, pharmaceutical industry |

Surface | Sand blasting, black anti-rust oil or galvanized , 3PE,etc. |

Package | Seaworthy Package, Plastic film,Ptywood Wooden Cases or wooden pallet or |

Certificate | ISO9001:2008, CE, API , SGS,BV, etc |

Capacity | 50000tons/year |

Advantages | 1.Reasonable price with excellent quality 2.Abundant stock and prompt delivery 3.Rich supply and export experience, sincere service 4. Reliable forwarder, 2-hour away from port. |

- Q: Aluminum bending or curling

- We focus on the technology that customers really need and provide long-term solutions to help customers make the best quality products at an efficient and low cost.We can provide:- bending technical consulting- material selection assistance- professional equipment selection assistance- assistance in vendor selection- bargaining help- personal training for technical personnel;- optimal solution

- Q: Can aluminum profiles be used for balustrades?

- Yes, aluminum profiles can be used for balustrades. Aluminum is a lightweight and durable material that is commonly used in construction for its strength and resistance to corrosion. It is also easy to shape and work with, making it ideal for creating various designs and styles for balustrades. Additionally, aluminum profiles can be powder coated or anodized to provide a decorative finish and enhance its durability. Overall, aluminum profiles offer a practical and aesthetically pleasing solution for balustrades in both residential and commercial settings.

- Q: Calculation of heat dissipation of aluminium profile radiator

- This requires software that is not easy to compute directly, and the formulas may pull out a long string and are inaccurateBecause the contact of the bottom of the profile is initiated by the heat source, the contact area is first set, which affects the distance and conduction angle of the thermal conductivityWhen you change this condition, the whole formula varies greatlyAgain, set convection and convection intensities, convection fluid properties and relative heat exchange efficienciesIn the radiator industry, there have been similar formulas, but only the natural convection settings, and in the heat under the state, heat dissipation at room temperature settingsProfessional software has many, FLOWTHEM, e-therm, ice-pake and so on, even Pro-E seems to be able to hang modules to do simulationSuggest going directly to software

- Q: Can aluminum profiles be used for outdoor applications?

- Outdoor applications can indeed utilize aluminum profiles. Aluminum, known for its versatility and durability, is resistant to corrosion, making it a suitable material for outdoor environments. Its exceptional weather resistance allows it to endure exposure to sunlight, rain, and temperature fluctuations without degradation. In various fields like construction, architecture, transportation, and outdoor furniture, aluminum profiles are frequently employed due to their strength, stability, and longevity, making them a favored option for outdoor projects. Moreover, protective coatings or anodizing can be applied to aluminum profiles to enhance their resistance to the elements commonly found outdoors.

- Q: What screws do you use for aluminum alloy profiles?

- Thank you. I'd like to have a knob on the aluminum alloy window. The hammer set screws are not. How to solve?Chasing the answerOh, it's you first use the tools of playing on my profile should be used instead of electric drill, electric hammer. If you are home to install a few, then suggest the use of self drilling screws, directly hit it, is the nail head with the drill bit of that. The machine needs to be secured before it can be used. Tapping screw before installation to make a small, it could not only drilling, reaming.

- Q: Are aluminum profiles resistant to mold or mildew?

- Indeed, aluminum profiles exhibit a remarkable resistance to the growth of mold and mildew. This is due to the inherent properties of aluminum, which render it highly impervious to these unsightly invaders. In contrast to materials like wood, which are susceptible to moisture damage and consequently encourage the proliferation of mold and mildew, aluminum remains unaffected by such issues. Moreover, aluminum profiles are frequently treated with protective coatings or finishes that further bolster their resilience against the encroachment of mold and mildew. Consequently, aluminum profiles represent an ideal choice for areas that are prone to excessive humidity or moisture, such as bathrooms or kitchens, where the growth of mold and mildew is a prevalent concern.

- Q: What are the different surface protection methods for aluminum profiles?

- There are several different surface protection methods available for aluminum profiles, each offering unique benefits and protection against various environmental factors. Some of the most common surface protection methods for aluminum profiles include anodizing, powder coating, and liquid coating. Anodizing is a popular surface treatment for aluminum profiles as it provides excellent corrosion resistance and enhances the appearance of the metal. This process involves immersing the aluminum profile in an electrolyte solution and applying an electric current to create an oxide layer on the surface. Anodizing can be carried out in various colors, allowing for customization and aesthetic appeal. Powder coating is another widely used method for protecting aluminum profiles. In this process, a dry powder is electrostatically applied to the surface of the metal and then cured in an oven. The powder melts and creates a durable, protective layer that offers resistance against scratches, UV rays, and chemicals. Powder coating is available in a wide range of colors and finishes, providing both protection and aesthetic options. Liquid coating, such as liquid paint or lacquer, can also be applied to aluminum profiles to provide protection against corrosion and other environmental factors. Liquid coatings offer versatility in terms of color and finishes, allowing for customization and meeting specific design requirements. However, compared to anodizing or powder coating, liquid coatings may be less durable and require more maintenance over time. Additionally, there are other surface protection methods for aluminum profiles, such as mechanical finishing techniques like brushing or polishing. These methods help to remove imperfections and create a smooth, visually appealing surface. In conclusion, the different surface protection methods for aluminum profiles include anodizing, powder coating, liquid coating, and mechanical finishing techniques. Each method offers distinct advantages in terms of corrosion resistance, durability, aesthetics, and customization options. The choice of surface protection method ultimately depends on the specific requirements, budget, and desired appearance of the aluminum profiles.

- Q: Is it possible to use aluminum profiles for outdoor applications like fences and railings?

- <p>Yes, aluminum profiles are commonly used for outdoor applications such as fences and railings. They are favored for their resistance to corrosion, lightweight properties, and durability. Aluminum can withstand harsh weather conditions without rusting, making it an ideal material for outdoor use. Additionally, it is low maintenance, as it does not require painting or frequent repairs. The profiles can be powder-coated or anodized for enhanced protection and aesthetic appeal.</p>

- Q: Can aluminum profiles be used in the production of electronics?

- Yes, aluminum profiles can be used in the production of electronics. They are commonly used for heat sinks, as aluminum has excellent thermal conductivity and can effectively dissipate heat generated by electronic components. Additionally, aluminum profiles can be used for structural support and enclosure purposes in electronic devices.

- Q: Is it possible to recycle aluminum profiles through the current recycling systems in place?

- <p>Yes, aluminum profiles can be recycled using existing recycling programs. Aluminum is one of the most recycled materials globally due to its non-toxic nature and the energy efficiency of recycling it. Most recycling programs accept aluminum, and aluminum profiles can be collected, sorted, and processed to be melted down and reused in new products. It's important to check with local recycling facilities to understand their specific guidelines and requirements for recycling aluminum profiles.</p>

Send your message to us

60 Degree Aluminum Tile Trim Profiles Elbow for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords