Aluminum Silicon Carbide Sheets - Special Alloy Extrusion Aluminum 1050 Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

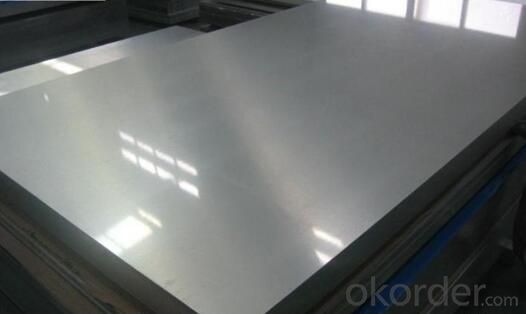

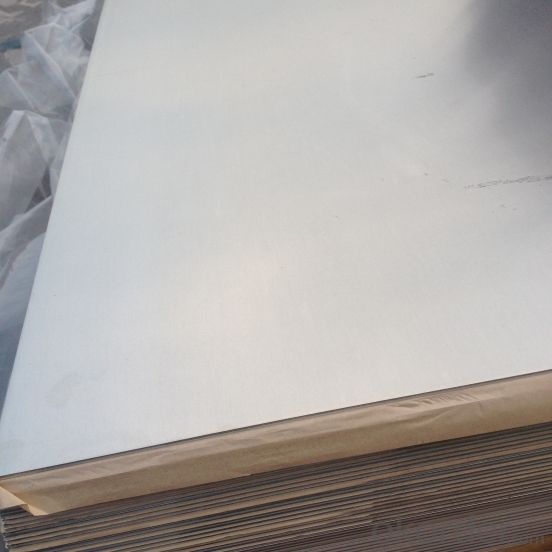

Aluminum Sheet for Making Aluminum Composite Panel

Aluminum sheet specifications:

1) Alloy : 1050 1060 1070 1100 2024 3003 3004 3105 3A21 5005 5052 5083 5754 5182 5454 5456 6061 6063 7075 8011 etc

2) Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.1mm to 300mm

4) Width:20mm to 3300mm

5)Length: ≤ 12000mm

6) Protective film can be added

7) Production Line: DC and CC production line

Discription:

Width: 50-800mm

Thickness: 8-25mic

Length: 3-300m

Character:

High-temperature sterilization

Made of advanced food grade alu material,no pollution

Eco-friendly, recoverable and recyclable

Application:

widely used for food cooking, freezing wrapping, storing etc, the main application are for household and catering, which are targeting for retail market and food service market, such as hypermarket, chain store and hotel, restaurant etc.

Packing:

One roll in an individual box or printed PP bag

Certain quantities in a standard carton

Depends on customer’s request

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q: Are the aluminum sheets suitable for welding?

- Yes, aluminum sheets are suitable for welding. Aluminum is a popular material for welding due to its lightweight, high strength-to-weight ratio, and corrosion resistance. However, it is important to note that welding aluminum requires specific techniques and considerations compared to other metals. Aluminum has a low melting point and high thermal conductivity, which makes it more challenging to weld compared to steel or other metals. Specialized welding processes, such as Tungsten Inert Gas (TIG) welding or Metal Inert Gas (MIG) welding with a spool gun, are commonly used for aluminum welding. Additionally, proper cleaning and preparation of the aluminum surface, as well as the use of appropriate filler materials, are crucial for achieving strong and durable welds. Overall, with the right equipment, techniques, and expertise, aluminum sheets can be successfully welded to create various structures and components.

- Q: Are aluminum sheets suitable for electrical busbars?

- Yes, aluminum sheets can be suitable for electrical busbars. Aluminum is a widely used material in the electrical industry due to its excellent electrical conductivity, lightweight nature, and affordability compared to other metals like copper. Aluminum sheets can be easily fabricated into the desired shape and size required for busbars, making them a versatile choice for electrical applications. Additionally, aluminum has good thermal conductivity, which helps in dissipating heat generated during electrical operations. However, it is important to note that aluminum has a lower electrical conductivity compared to copper, so it may require larger cross-sectional areas to achieve the same electrical performance. It is essential to consider the specific requirements of the electrical system and consult with experts to determine if aluminum sheets are suitable for a particular busbar application.

- Q: I have no idea, and I can't figure this out, and neither can my aunt and she's super smart. It's this project that's due on Monday, and if I can't get it turned in, then I get detention and a failing lab grade. The only information I have is it's $2.96 for a roll of aluminum, it contains 2.96 square meters, and it weighs .995 grams...

- say it's a trick question, because it there is no denotational value for a single aluminum atom :/

- Q: Can 101 aluminum sheets be stamped or engraved?

- Certainly! Stamping or engraving 101 aluminum sheets is indeed possible. Aluminum, being a highly adaptable material, lends itself well to different manipulation techniques. Stamping entails exerting pressure to imprint a design or pattern onto the aluminum sheet, whereas engraving involves carving or incising a design onto it. Both methods can be applied to aluminum sheets, including those composed of 101 aluminum alloy. Nevertheless, it is crucial to take into account the thickness and hardness of the sheets, as these variables might impact the precision and sharpness of the stamped or engraved design.

- Q: Are 101 aluminum sheets suitable for food packaging?

- Indeed, 101 aluminum sheets prove to be apt for food packaging purposes. The food packaging industry widely embraces aluminum owing to its remarkable attributes. Notably, it boasts a lightweight nature, durability, and resilience against corrosion, rendering it an ideal substance for maintaining the freshness and caliber of food products. Moreover, aluminum serves as a commendable shield against light, moisture, and oxygen, thereby prolonging the shelf life of packaged edibles. Thus, it is evident that opting for 101 aluminum sheets is a fitting decision for food packaging endeavors.

- Q: some car manufactures use aluminium car body on a steel sub-frame. explain, using electrode potential what would happen if a weak acid was to become trapped in the space between these two metals!! any current plzz help, its for my assignment, and i dont understand

- Chemistry is all about how atoms exchange electrons. Some kinds like electrons better than others, and this is the basis of electrochemistry and Redox reactions. It all starts with the acid: HAcid - H(+) + Acid(-) The important thing is the H(+) ion, which is positive because it is a Hydrogen atom which has lost an electron. This leaves it with a positive charge, since it is nothing but a positive proton at this point. Fe + 2H(+) - Fe(+2) + H2 The above is a typical reaction between an acid and most metals. The H(+) ions strip an electron from the metal to form a metal ion and Hydrogen gas. What has happened is the Hydrogen ions have oxidized the Iron. The Iron in turn has reducted the Hydrogen. In terms of electrochemistry, there are two half reactions going on simutaneously. First, the Iron atoms generate two negative electrons: Fe - Fe(+2) + 2e(-) = OXIDATION OF IRON Then the Hydrogen ions combine with the electrons to form Hydrogen gas: 2H(+) + 2e(-) - H2 = REDUCTION OF HYDROGEN Note that in both reactions, the charges are equal on either side of the reaction. The next part of this process happens when the Iron ions come into contact with the Aluminum metal: 3Fe(+2) + 2Al - 2Al(+3) + 3Fe Note the Iron ions are recting exactly the same way the Hydrogen ions did. In other words, they are oxidizing the Aluminum. The Aluminum is now reducing the Iron. The net result of this is that the acid rusts the Iron and then the Iron rusts the Aluminum. The end result is the production of tiny amounts of Hydrogen gas, The Iron being displaced from where it had initially been, and the solid Aluminum discintegrating into some form of Aluminum salt. Calculations involve something called an electrochemical series and the voltage is given using the Nerst equation. Both the electrochemical table and the equation can be found in any chemistry textbook.

- Q: What is the thickness range available for aluminum sheets?

- The specific requirements and applications can cause the thickness range of aluminum sheets to vary. Typically, aluminum sheets come in a variety of thicknesses, ranging from very thin at 0.006 inches (0.15mm) to very thick at 0.5 inches (12.7mm) or even thicker in certain cases. It should be noted that the supplier or manufacturer may have different availability of specific thicknesses. Furthermore, specialized fabrication processes can often provide custom thicknesses.

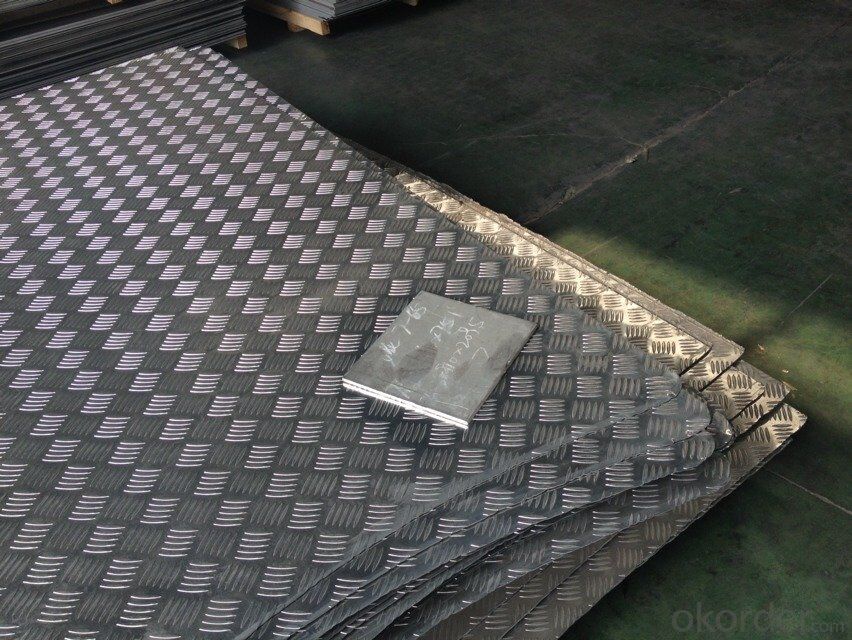

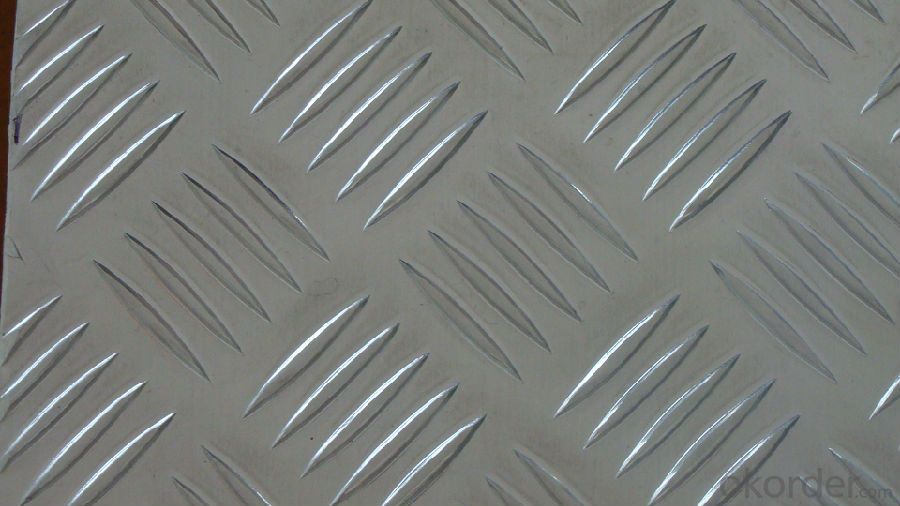

- Q: What are the different types of aluminum sheets available?

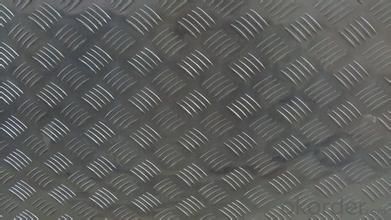

- There are several different types of aluminum sheets available, including plain aluminum sheets, embossed aluminum sheets, perforated aluminum sheets, and painted aluminum sheets. Each type has its own unique attributes and applications.

- Q: Are aluminum sheets suitable for use in electrical applications?

- Yes, aluminum sheets are suitable for use in electrical applications. Aluminum is an excellent conductor of electricity, and its high conductivity allows for efficient transmission of electrical current. Aluminum sheets are commonly used in electrical applications such as power transmission lines, electrical wiring, and electrical enclosures. Additionally, aluminum is lightweight, which makes it easier to handle and install. It is also resistant to corrosion, which ensures long-term durability and reliability in electrical systems. However, it is important to note that aluminum has a lower conductivity compared to copper, so it may require larger gauge sizes to compensate for this difference. Overall, aluminum sheets are a viable and cost-effective option for various electrical applications.

- Q: This question asks for the various types of adhesives that can be used for bonding aluminum profiles when constructing exterior cladding.

- <p>For bonding aluminum profiles in exterior cladding, several types of adhesives are commonly used. These include: 1. Structural adhesives, which provide strong and durable bonds suitable for load-bearing applications. 2. Silicone sealants, known for their flexibility and resistance to weathering, making them ideal for sealing gaps and joints. 3. Acrylic adhesives, which offer good adhesion and flexibility, and are often used for bonding aluminum to other materials. 4. Epoxy adhesives, known for their high strength and resistance to chemicals, making them suitable for demanding environments. 5. Polyurethane adhesives, which provide strong bonds and excellent resistance to moisture and temperature changes. The choice of adhesive depends on factors such as the specific application, environmental conditions, and required performance characteristics.</p>

Send your message to us

Aluminum Silicon Carbide Sheets - Special Alloy Extrusion Aluminum 1050 Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords