Aluminum Sheets in South Dakota - Aluminium Plain Sheet for Construction and Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

3003-H14 Aluminum Sheet - (ASTM B209) Excellent weldability, formability, with good corrosion resistance make 3003 Aluminum Plate a popular and economical choice. 3003 Aluminum Plate has a smooth, shiny finish and is popular for many cosmetic and industrial applications, including: decorative trim, fuel tanks, food & chemical handling, trailer siding & roofing, etc.

Non-magnetic, Brinell = 40, Tensile = 22,000, Yield = 21,000 (+/-)

5052-H32 Aluminum Sheet - (ASTM B20) Superior corrosion resistance, good weldability, with excellent formability, makes 5052Aluminum Plate a common choice for chemical, marine or saltwater applications. 5052 Aluminum Plate applications include: tanks, drums, marine hardware, boat hulls, etc.

Non-magnetic, Brinell = 60, Tensile = 33,000, Yield = 28,000 (+/-)

6061-T651 Aluminum Sheet - (ASTM B209, QQ-A 250/11) Offers a combination of increased strength, corrosion resistance, and machinability making it the most widely used aluminum grade. 6061 Aluminum Plate is heat treatable, resists cracking due to stress, is easy to weld and machine, but limited on formability. 6061 Aluminum Plate is ideal for structural framing, base plates, gussetts, motorcycle & automotive parts, etc.

Non-magnetic, Brinell = 95, Tensile = 45,000, Yield = 40,000 (+/-)

- Q: Can aluminum sheets be used for curtain walls?

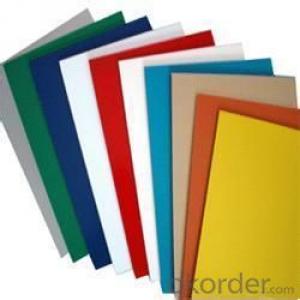

- Certainly, curtain walls can utilize aluminum sheets. Aluminum proves to be a favored option for curtain wall systems because of its lightweight, enduring, and corrosion-resistant properties. Aluminum sheets can be effortlessly molded into different forms and dimensions, rendering them ideal for crafting the structural framework of curtain walls. Moreover, aluminum can undergo coating or anodization processes to enhance its visual appeal and offer extra safeguard against weather conditions. Consequently, aluminum sheets emerge as a versatile and pragmatic material for erecting curtain walls in both commercial and residential structures.

- Q: Is the chemical formula for Aluminum Sulfate Al2(SO4)3?How and why is Al2(SO4)3 wrong?

- Formula For Aluminum Sulfate

- Q: What is the typical price range for aluminum sheets?

- The price of aluminum sheets can differ based on several factors, including thickness, grade, size, and quantity required. Typically, aluminum sheets can be priced anywhere between $0.50 and $5 per square foot. Thinner sheets or lower-grade aluminum are generally found at the lower end of the price spectrum, whereas thicker sheets or higher-grade aluminum tend to be on the higher end. It's worth mentioning that market conditions, location, and supplier can also impact prices. Therefore, it is recommended to consult specific suppliers or conduct market research for the most precise and current pricing details.

- Q: Can aluminum sheets be used in marine environments?

- Indeed, aluminum sheets prove to be applicable in marine settings. Owing to its exceptional resistance to corrosion, aluminum stands as a prevalent choice for various marine purposes. The formation of a safeguarding oxide layer on its exterior inhibits further corrosion when exposed to saltwater or other corrosive substances commonly present in marine environments. Possessing both lightweight and robust properties, aluminum sheets become an optimal selection for a range of marine structures including boat hulls, decks, and superstructures. Furthermore, aluminum exhibits remarkable durability and an extended lifespan, thereby enhancing its appropriateness for marine applications.

- Q: are there any hazards in aluminium?

- The metal, yes. But you can always face the risk of get cut if it has sharp edges.

- Q: What is the classification of 6061106070 aluminum plate, which respectively represent what it means to ask God for help

- Three, the beginning of the aluminum manganese alloy, 3003, 3004, 3015 and so on, the use of a wide range, also known as rust aluminum. Four, the beginning of the four Department of aluminum is aluminum silicon alloy, on behalf of 4A01 five, the beginning of the aluminum magnesium alloy, there are 5052, 5083 and so on, the use of more than three series, the domestic manufacturers can do.

- Q: What are the different cutting tools used for aluminum sheets?

- There are several cutting tools that can be used for aluminum sheets, including power shears, hacksaws, circular saws with carbide-tipped blades, and plasma cutters. Each tool has its own advantages and is suitable for different applications depending on the thickness and size of the aluminum sheet.

- Q: What is the melting point of 101 aluminum sheets?

- Approximately 660 degrees Celsius or 1220 degrees Fahrenheit is the melting point of 101 aluminum sheets.

- Q: Are the aluminum sheets suitable for manufacturing power distribution panels?

- Yes, aluminum sheets are suitable for manufacturing power distribution panels. Aluminum is a lightweight and durable material with excellent electrical conductivity, making it ideal for use in power distribution systems. Additionally, it is highly resistant to corrosion, which is crucial for ensuring the longevity and reliability of the panels.

- Q: what kind of abradant should be used in the deburring of aluminum sheets? How to grind?

- you can use deburring brush,grinding fluid,abrasive powder and other consumables.

Send your message to us

Aluminum Sheets in South Dakota - Aluminium Plain Sheet for Construction and Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords