Aluminum Sheets in New Jersey - Prepainted Aluminum Coils for Outer Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

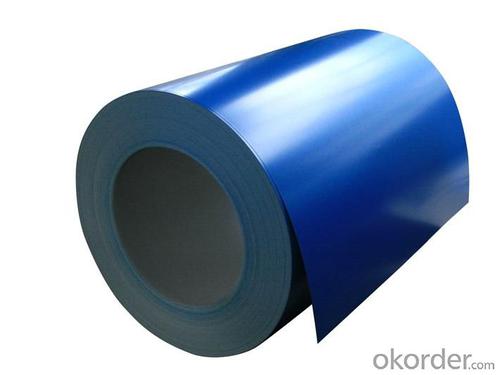

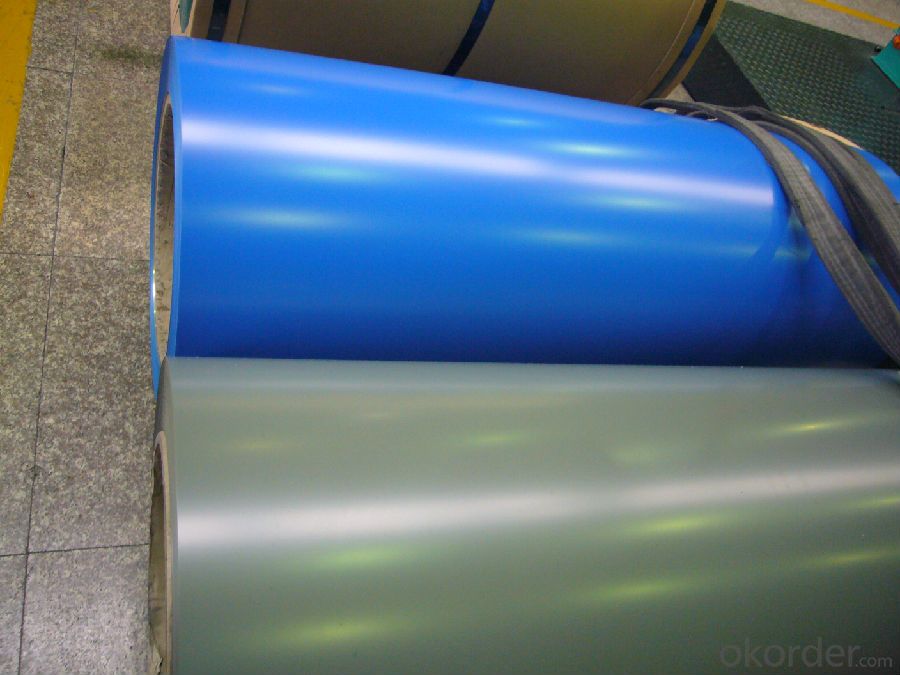

1.Structure of Prepainted Aluminium Coils for Outer Decoration

Prepainted Aluminium Coils for Outer Decoration are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.

2. Main features of Prepainted Aluminium Coils for Outer Decoration

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Coating | Coating Thickness | Weight |

| AA1050 | H14 | Polyester | 20-25microns | about 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: A sample of aluminum and a sample of steel have superficially identical microstructures. Which would you expect to be stronger, and why?

- By stronger I am assuming you mean it has a higher sheer point... Yes, standard iron-carbon alloys do have a higher sheer point because of the carbon atom placement in the lattice. You see, whenever a ferrous alloy is cooled rapidly, carbon atoms dont have time to move away from the iron, which is also known as ferrite. The steel becomes so rigid that the carbon atoms become trapped in the lattice as the iron atoms try to transform the cubic structure. The result is a structure where the carbon atom is an interstitial member. This makes it a tetragonal structure(martensitic), which takes allot of energy to sheer. This is not the only way, though, as there are a number of heat-treatment cycles for altering the structure of steel.

- Q: Can aluminum sheets be anodized with custom colors?

- Yes, aluminum sheets can be anodized with custom colors. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of aluminum, and during this process, dyes can be applied to achieve a wide range of custom colors.

- Q: Can aluminum sheets be used for chemical storage containers?

- Yes, aluminum sheets can be used for chemical storage containers. Aluminum is a corrosion-resistant metal that can withstand the chemical reactions of various substances, making it suitable for storing a wide range of chemicals. Additionally, aluminum is lightweight, durable, and easily formable, making it a practical choice for manufacturing chemical storage containers.

- Q: This question asks for guidance on selecting aluminum sheets based on their intended use, implying a need for criteria or factors to consider when making such a choice.

- <p>When choosing aluminum sheets for different purposes, consider the following factors: 1) Thickness: Depending on the strength and durability required, select the appropriate thickness. 2) Alloy Type: Different alloys have varying properties; for instance, 1100 series is purest and softest, while 6000 series offers high strength. 3) Surface Finish: Choose between mill finish, anodized, or coated finishes based on aesthetic and functional needs. 4) Temper: This refers to the hardness and strength, with options like O (annealed), H14 (strain hardened), and T6 (solution heat treated). 5) Application: Consider the specific use, such as construction, automotive, or aerospace, as each may require specific properties. Always consult with a supplier or engineer for advice tailored to your project's needs.</p>

- Q: is aluminum foil spacer poisonous after heating?

- many baked food will use aluminum foil.

- Q: I'm making a project for class and I bought a 10 Inch long 5mm thick aluminum/metal, How do you cut it WITHOUT large machinery? is there any power tools adapters or tools that can do this job without a problem?Here is what I have to do:*Cut the metal into ~1x1 and 2X2inch squares*Somehow shave a circle about 2mm deep without going trough the 5mm aluminum (Shaded gray)*Drill a hole right through the 5mm (right in the center)*Drill screw holes on each cornerI provided a really basic pic of what I'm trying to dohttp://img204.imageshack.us/img204/487/77845398.pngRED=backgroundGRAY=drilled 2mm deep WITHOUT GOING THROUGHRED HOLES=screw holes with threadsPlz help need to finish this by friday!PS: Screw holes, and other sizes don't matter right now I'm just trying to figure out what tools/tool adapters I need thanks!

- A rotary tool may do the trick. You would have to have a steady hand and also be able to hold the aluminum securely in place.

- Q: Are aluminum sheets suitable for aerospace fuel tanks?

- Yes, aluminum sheets are suitable for aerospace fuel tanks. Aluminum is a commonly used material in the aerospace industry due to its lightweight yet durable properties. It offers a good strength-to-weight ratio, making it ideal for fuel tanks that need to be strong enough to withstand the forces of flight while keeping the overall weight of the aircraft as low as possible. Additionally, aluminum is resistant to corrosion, which is crucial for aerospace fuel tanks as they are exposed to various fuels and environmental conditions. The ease of fabrication and availability of aluminum also make it a cost-effective choice for aerospace applications. Overall, aluminum sheets are a suitable material for aerospace fuel tanks due to their strength, lightweight nature, corrosion resistance, and cost-effectiveness.

- Q: I saw a guy on ebay take a washed out paint can fill it full of lighted charcoal bricks and a tin can in the middle. He was melting aluminum cans in there then pured it into a mold. Does this really work and does anyone have any good ideas on how else to do this?

- Aluminum alloys melt at around 1200 degrees, aluminum cans maybe somewhat lower, but I doubt a tin can would hold up long enough to melt much aluminum, and you would need to be very careful, any moisture in your mold will cause the aluminum to literally explode back into your face. I am not saying it couldn't be done, but you really would need lots of safety equipment before trying it.

- Q: How do you protect aluminum sheets from scratches?

- If you want to prevent scratches on aluminum sheets, there are several measures you can take: 1. Be cautious when handling: Always keep in mind that aluminum sheets are susceptible to scratches. Avoid dragging or sliding them on rough surfaces, as this can cause scratches. Instead, lift and place them gently on a clean and smooth surface. 2. Use protective coverings: Consider using plastic film or paper to cover aluminum sheets before storing or transporting them. These coverings act as a barrier and prevent direct contact with other surfaces, reducing the chances of scratches. Make sure the coverings are clean and free from dirt or debris. 3. Store in a safe environment: Store aluminum sheets in a clean and dry environment when they are not in use. Avoid storing them with abrasive materials or objects that may scratch them. You can also use dividers or separators to create individual compartments for each sheet, preventing them from rubbing against each other. 4. Clean with care: Use a soft cloth or sponge that is non-abrasive when cleaning aluminum sheets. Avoid using wire brushes or rough materials that can cause scratches. Additionally, use a mild detergent or aluminum cleaner specifically designed for this purpose. Rinse the sheets thoroughly and dry them completely to prevent any moisture-related damage. 5. Apply a protective coating: Another option to protect aluminum sheets from scratches is to apply a protective coating. There are various types of coatings available, such as clear lacquers or specialized aluminum protectants. These coatings create a thin barrier on the surface of the aluminum, providing an extra layer of protection against scratches. By following these steps, you can significantly minimize the risk of scratches on your aluminum sheets and preserve their appearance and integrity over time.

- Q: What specific conditions are necessary for the storage and transportation of aluminum sheets to ensure their quality and safety?

- <p>Yes, there are special requirements for storing and transporting aluminum sheets. Aluminum sheets should be stored in a dry, cool place to prevent moisture and temperature extremes which can cause warping or corrosion. They should be stacked flat and evenly to avoid bending or denting. When transporting, aluminum sheets should be secured to prevent shifting during transit, which can lead to damage. Protective coverings may be used to shield the sheets from dirt, scratches, or other potential hazards. It's also crucial to handle the sheets carefully to avoid bending or denting, which can occur if they are not properly supported during transport.</p>

Send your message to us

Aluminum Sheets in New Jersey - Prepainted Aluminum Coils for Outer Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords