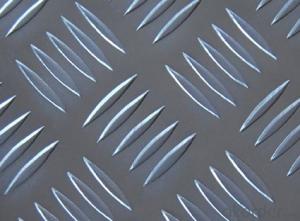

Aluminum Sheets in Nevada - Alu Plate with Five-bars Pattern

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

Alu Plate

Aluminum trade plate have great suctility,heat conductivity, anti-corrosion and moisture resistance properties.

Alloy: AA1050,1060, 1100, AA3003, 3005, 3015, 5052, 5754, 5083,8011, etc

Temper: H14/16/18/22/24/32,HO etc.

Thickness:0.2mm—100mm

Width:100mm—2300mm (Can be slitted)

Application:

Anti-sliperypurpose in vehicles, packing and appliance, decorative purpose

- Q: Can aluminum sheets be used for solar panels?

- Yes, aluminum sheets can be used for solar panels. Aluminum is a commonly used material in the construction of solar panels due to its lightweight, durability, and excellent heat dissipation properties. The use of aluminum helps to reduce the overall weight of the solar panels, making them easier to install and transport. Additionally, aluminum is highly resistant to corrosion, ensuring the longevity of the solar panels even in harsh weather conditions.

- Q: Can aluminum sheets be used for decorative panels?

- Yes, aluminum sheets can be used for decorative panels. Aluminum is a versatile material that can be easily shaped, textured, and colored, making it suitable for various decorative applications. Its lightweight nature, durability, and resistance to corrosion also make it a popular choice for decorative panels in both indoor and outdoor settings.

- Q: Can aluminum sheets be perforated for decorative or functional purposes?

- Yes, aluminum sheets can be perforated for both decorative and functional purposes. Perforating aluminum sheets allows for the creation of intricate patterns or designs and also enhances the sheet's functionality by improving ventilation, reducing weight, or enhancing acoustic properties.

- Q: This question asks about the impact of aluminum sheets on the air quality inside a building.

- <p>Aluminum sheets themselves do not directly affect indoor air quality. They are inert materials that do not emit volatile organic compounds (VOCs) or other harmful substances. However, the installation process might involve adhesives or sealants that could release VOCs temporarily. Proper ventilation during and after installation can mitigate this issue. Additionally, aluminum sheets can contribute to better air quality by enhancing thermal performance, reducing energy consumption for heating and cooling, and indirectly lowering emissions from power plants.</p>

- Q: Can aluminum sheets be used as a substitute for steel in certain applications?

- Certain applications can utilize aluminum sheets as a replacement for steel. Aluminum, a versatile and lightweight material, offers numerous advantages over steel. Its high strength-to-weight ratio allows it to deliver comparable strength while being considerably lighter. This quality makes aluminum sheets an outstanding option for weight-sensitive applications, like those in the aerospace, automotive, and transportation industries. Furthermore, aluminum boasts exceptional corrosion resistance, negating the necessity for supplementary protective coatings or treatments. Consequently, aluminum sheets are suitable for employment in marine environments or other corrosive settings. Additionally, aluminum sheets possess remarkable thermal conductivity, making them ideal for applications that necessitate heat dissipation, such as heat exchangers or radiators. Moreover, aluminum is more pliable than steel, facilitating easier shaping and forming. This attribute renders aluminum sheets suitable for applications that require intricate or complex designs. However, it is vital to acknowledge that aluminum has lower tensile strength in comparison to steel. Consequently, in applications demanding substantial load-bearing capacities or structural integrity, steel may remain the preferred choice. In such instances, a thorough evaluation of specific requirements and trade-offs between weight, strength, and cost should be conducted before opting to use aluminum sheets as a steel substitute.

- Q: Can aluminum sheet be used for chemical processing?

- Aluminum sheet is indeed applicable for chemical processing. Its versatility and resistance to corrosion make it a sought-after material in various industries, including chemical processing. The remarkable attribute of aluminum is its ability to withstand numerous chemicals, such as acids, alkalis, and salts. Therefore, it is well-suited for situations where exposure to corrosive substances is prevalent. Moreover, aluminum possesses the advantages of being lightweight, long-lasting, and possessing excellent thermal conductivity. These qualities make it a prime choice for facilitating heat transfer and promoting energy-efficient procedures in chemical industries. However, it is crucial to assess the specific chemical environment and seek guidance from experts to guarantee the compatibility of aluminum with the particular chemicals and conditions involved in the process.

- Q: what is better for my 96 mustang gt. porting and polishing my stock heads or getting aluminum heads. also could i do a 3v conversion?

- Port and polish could give you loads of power depending on how big and clean you want to go. Aluminum heads are nice, they are very expensive and will only disperse heat faster. Although they can warp as well if they are under too much heat. If I had to choose, I would choose the port and polish with a roller rocker rail and a high flow electric water pump. I'm sorry but I'm not sure what a 3v is?

- Q: Are aluminum sheets suitable for automotive body reinforcements?

- Yes, aluminum sheets are suitable for automotive body reinforcements. Aluminum is a lightweight material that offers high strength-to-weight ratio, making it an ideal choice for automotive applications. It provides excellent corrosion resistance, which is crucial for vehicles exposed to various weather conditions and road salts. Additionally, aluminum sheets can be easily formed and welded, allowing for seamless integration into the body structure. The use of aluminum sheets in automotive body reinforcements helps reduce the overall weight of the vehicle, leading to improved fuel efficiency and performance. Furthermore, aluminum is a recyclable material, aligning with the automotive industry's increasing focus on sustainability. Hence, aluminum sheets are indeed a suitable choice for automotive body reinforcements.

- Q: Can aluminum sheets be used for electronic enclosures?

- Yes, aluminum sheets can be used for electronic enclosures. Aluminum is a lightweight and durable material that offers excellent heat dissipation properties, making it suitable for protecting electronic components. Additionally, aluminum sheets can be easily fabricated to create custom enclosures that provide electromagnetic shielding and protection against environmental factors.

- Q: What are the different types of surface treatments available for powder-coated aluminum sheets?

- Powder-coated aluminum sheets offer several options for surface treatments. Among the most common are anodizing, chemical etching, and mechanical finishing. Anodizing involves immersing the aluminum sheets in an electrolytic solution and applying an electric current. This creates a protective oxide layer on the surface, enhancing durability and corrosion resistance. It also provides a decorative finish with a wide range of colors. Chemical etching is another method. It involves applying a chemical solution to the aluminum sheets, creating a textured or patterned surface. This improves aesthetics and allows for unique designs. Mechanical finishing techniques, like brushing or polishing, can also be used. Brushing creates a brushed or linear pattern, while polishing creates a smooth and glossy finish. Furthermore, there are specialized surface treatments for specific applications. Chromate conversion coating improves adhesion of adhesives or paints, while clear coatings offer added protection against UV radiation. Ultimately, the choice of surface treatment depends on the desired aesthetic, functionality, and durability requirements of the application.

Send your message to us

Aluminum Sheets in Nevada - Alu Plate with Five-bars Pattern

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords