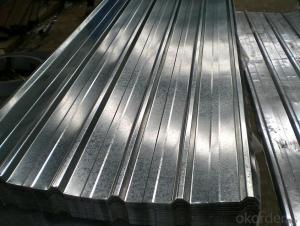

Aluminum Sheets in Indiana - Corrugated Aluminum Tile in Different Corrugation Profiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Corrugated Aluminum Tile in Different Corrugation Profiles

Specifications

Alloy NO. | Thickness | Width | Length | Production line | Circulation size |

1050 1060 1100 3003 | 0.3-9.5mm | 800--2200mm | 1000--10000mm | DC,CC | 1220*2440mm 1250*2500mm 1500*3000mm 1000*2000mm

|

5052 5083 5454 5754 5086 | 0.5-150mm | 800--2200mm | 1000--6000mm | DC | |

6061 | 5-150mm | 800--2200mm | 1000--10000mm | DC | |

7075 | 6-150mm | 800--2200mm | 1000--10000mm | DC | |

Packing | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | ||||

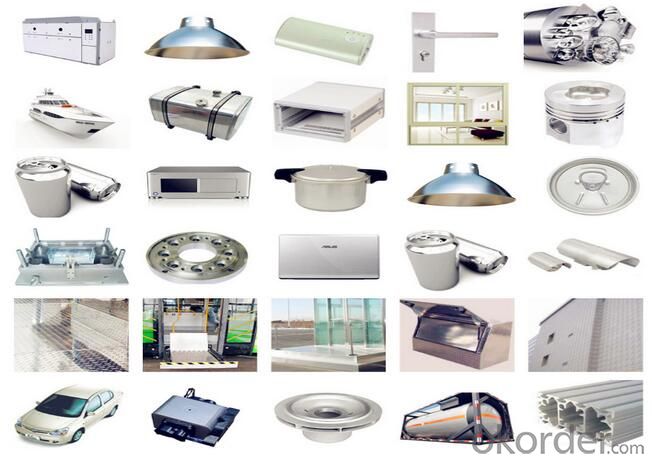

Application | decoration:ceilings,walls,furniture,cabinets,elevators,signs,name plate, transportation, cookware, household appliances:refrigerators,microwave ovens, machinery, mold making,aerospace and military aspects, auto, PP cap , construction etc | ||||

Standard | Chemical Composite: GB/T 3190-2008, JIS, EN, ASTM | ||||

Mechanical Property: GB/T 3880.2-2012, JIS, EN, ASTM | |||||

MOQ | 5TONS | ||||

Kind attention | Specifications can be customized as the customer’s requirements | ||||

Application

FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons.

- Q: Can aluminum sheets be used for cookware?

- Cookware can indeed utilize aluminum sheets. Due to its exceptional heat conductivity and lightweight nature, aluminum remains a favored material for cookware. In the construction of cooking utensils like pots, pans, and baking sheets, aluminum sheets frequently serve as the base or core material. To enhance durability and user-friendliness, these sheets are often coated with a nonstick or ceramic layer. Nonetheless, it is crucial to recognize that pure aluminum can react with certain acidic or alkaline foods, resulting in a metallic taste or discoloration. To prevent such occurrences, most aluminum cookware is anodized or coated, establishing a barrier between the food and the aluminum surface. All in all, aluminum sheets prove to be an adaptable and widely employed option for cookware in both professional and domestic kitchens.

- Q: the amp setting when welding aluminum tig? and what color should the electrode feeder be bronze or chrome grey? u know the one u use with your hands

- Best electrodes to use for Aluminum welding is 1.5% lanthanum oxide (gold color code.). 2% zirconia (brown) or 2% thorium oxide (red) can also be used. Note that zirconia-doped electrodes should never be used for DC welding. A lot of welders like to quote offhand the rule 1 amp for every 0.001 inch of thickness. This applies to steel, stainless, and nickel alloys only. Due to the lower melting point, lower specific heat capacity, and higher thermal conductivity of of Al, this rule should NOT be used for Al! I recommend welding a test piece first with the same joint configuration and thickness of the part you intend to weld. Note that fillet welds require more current than butt welds or edge welds. Start out by using 2/3 amp per 0.001 of thickness, in other words, reduce the current of the above rule by about 30-40% . Make 3 test weld, then check to see if there's any visible penetration on the other side. If you don't see any through-pentration at all, increase the current by about 10-20 amps and test again.

- Q: 3mm heavy aluminum plate, multiple cubic meters per cubic meter?

- If calculated according to 2.73 density, the theory of a 3MM*1000MM*1000MM weight is 8.19KG. and the specifications of the aluminum flat stacked together what number should be in the 300-333 cubic meters of estimated.

- Q: Is aluminum sheet resistant to UV rays?

- Yes, aluminum sheet is resistant to UV rays.

- Q: Is it possible to use aluminum sheets in environments with high temperatures?

- <p>Yes, aluminum sheets can be used in high-temperature environments, but with certain considerations. Aluminum has a high melting point of around 660掳C (1220掳F), which allows it to withstand high temperatures. However, its mechanical properties can degrade over time when exposed to sustained high temperatures, especially above 200掳C (392掳F). For applications requiring long-term exposure to high temperatures, special heat-resistant aluminum alloys or coatings may be necessary to maintain structural integrity and performance. It's also important to consider the specific conditions and the maximum temperature the aluminum will be exposed to when determining its suitability for a high-temperature application.</p>

- Q: Are aluminum sheets suitable for roofing systems?

- Yes, aluminum sheets are suitable for roofing systems. They are lightweight, durable, corrosion-resistant, and can withstand harsh weather conditions. Additionally, aluminum sheets have a long lifespan, require minimal maintenance, and are eco-friendly, making them a popular choice for roofing in many applications.

- Q: How is the coated aluminum mirror plate produced?

- Film board is in the Aluminum Alloy substrate coated a layer of film, film or film with high light color, surface coated with adhesive compound and into professional. Film covered board - characterized by coated panels, bright luster, can choose a variety of colors, waterproof and fire, with excellent durability (weather resistance, corrosion resistance, chemical resistance) and dirt resistance, anti UV superior performance. Different brands of coated plastic board, its substrate material and thickness of different film covered material and thickness are also different.

- Q: What does 3003-O aluminum mean?

- H-- strain hardening statusO-- annealed state (the softest of all States)T-- heat treatment status

- Q: I have to repair a cracked aluminum engine block. What alumunum epoxy should I use?

- Best Epoxy For Aluminum

- Q: Are aluminum sheets suitable for electronic components?

- Yes, aluminum sheets are suitable for electronic components. Aluminum is commonly used in the production of electronic components due to its excellent conductive properties, lightweight nature, and high thermal conductivity. It is often utilized in circuit boards, heat sinks, and enclosures for electronic devices.

Send your message to us

Aluminum Sheets in Indiana - Corrugated Aluminum Tile in Different Corrugation Profiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords