Aluminum Sheets for Semi Trailer Wall - 5 Bars Embossed Aluminum Sheet 5052 Alloy for Transportation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Five Bars Embossed Aluminum Sheet 5052 Alloy for Transportation

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC |

TEMPER | H14,H18,H24,H26,H32 |

THICKNESS | 0.2MM-20MM |

WIDTH | 10mm-1500mm |

COIL WGT | 2Mt - 3Mt |

Coil ID | 20" |

SURFACE | Diamond, Stucco ,Bars etc |

STANDARD | GB/T 3880-2006 |

2. Application of Five Bars Embossed Aluminum Sheet 5052 Alloy for Transportation

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Five Bars Embossed Aluminum Sheet 5052 Alloy for Transportation

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

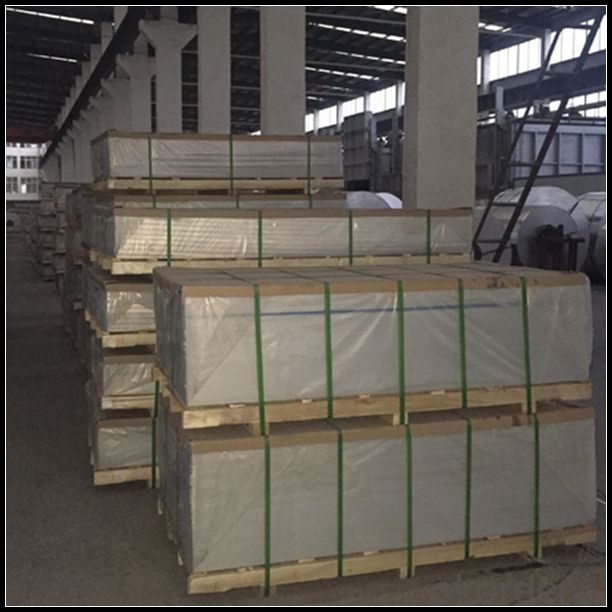

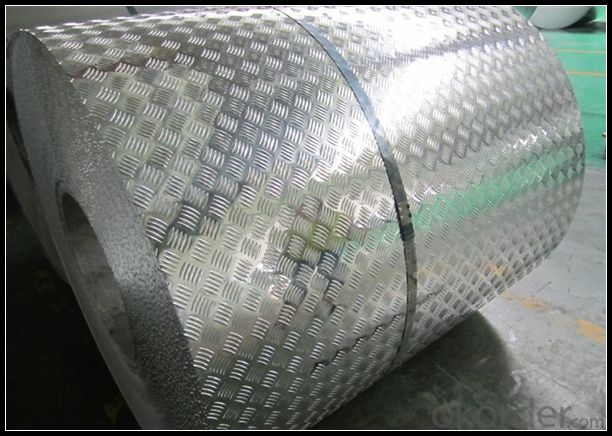

5. Image of Five Bars Embossed Aluminum Sheet 5052 Alloy for Transportation

6. Package and shipping of Five Bars Embossed Aluminum Sheet 5052 Alloy for Transportation

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum sheets suitable for beverage cans?

- Yes, aluminum sheets are suitable for beverage cans. Aluminum is a widely used material in the beverage industry due to its unique properties. It is lightweight, corrosion-resistant, and provides an excellent barrier against light, oxygen, and moisture, which helps to preserve the quality and freshness of the beverage. Additionally, aluminum is easily formable, allowing for the production of various can shapes and sizes. It is also recyclable, making it an environmentally friendly choice. Overall, aluminum sheets are an ideal material for beverage cans, meeting both functional and sustainability requirements.

- Q: 2mm aluminum welding with oxygen welding or argon arc welding good?

- 2 mm thickness of aluminum welding, argon arc welding preferred.2 mm thickness aluminum plate, in order to ensure the quality of welding and weld strength, the first choice should be: inverter square wave pulse TIG welding machine welding. According to the specific material and grade of the aluminum plate, the aluminum welding wire matched with the base material is selected.

- Q: What are the advantages of using aluminum sheet in construction?

- There are several advantages to using aluminum sheet in construction. Firstly, aluminum is a lightweight material, making it easier to handle and transport on construction sites. This reduces the need for heavy machinery and equipment, resulting in cost savings and improved efficiency. Secondly, aluminum has excellent corrosion resistance properties. Unlike other metals, such as steel, aluminum does not rust or corrode when exposed to moisture or harsh weather conditions. This makes it highly durable and suitable for outdoor applications, such as roofing or cladding. Additionally, aluminum is a highly versatile material that can be easily shaped and formed into different sizes and profiles. This allows for greater design flexibility, enabling architects and engineers to create innovative and unique structures. Moreover, aluminum is a sustainable material. It is 100% recyclable, meaning that it can be reused indefinitely without any loss in quality or performance. This makes it an environmentally friendly choice for construction projects, as it helps reduce waste and minimize the carbon footprint. Furthermore, aluminum has excellent thermal and electrical conductivity properties. It reflects heat and light, helping to maintain comfortable indoor temperatures and reduce energy consumption. It is also an excellent conductor of electricity, making it ideal for electrical wiring and components in buildings. Lastly, aluminum is a cost-effective material in the long run. Although it may have a higher initial cost compared to other building materials, its low maintenance requirements and long lifespan offset these costs over time. It does not require painting or regular upkeep, saving both time and money in the maintenance and repair of structures. In conclusion, the advantages of using aluminum sheet in construction include its lightweight nature, corrosion resistance, versatility, sustainability, thermal and electrical conductivity, and cost-effectiveness. These qualities make it a highly desirable material for a wide range of construction applications.

- Q: Can aluminum sheets be used for curtain walls?

- Certainly, curtain walls can utilize aluminum sheets. Aluminum proves to be a favored option for curtain wall systems because of its lightweight, enduring, and corrosion-resistant properties. Aluminum sheets can be effortlessly molded into different forms and dimensions, rendering them ideal for crafting the structural framework of curtain walls. Moreover, aluminum can undergo coating or anodization processes to enhance its visual appeal and offer extra safeguard against weather conditions. Consequently, aluminum sheets emerge as a versatile and pragmatic material for erecting curtain walls in both commercial and residential structures.

- Q: Are aluminum sheets resistant to chemicals?

- Yes, aluminum sheets are generally resistant to many chemicals. Aluminum has a natural oxide layer on its surface that provides a protective barrier against corrosion and chemical reactions. This oxide layer is stable and resists most acids, alkalis, and organic solvents. However, aluminum can be corroded by certain chemicals, such as strong acids or bases, and some halogenated compounds. Additionally, prolonged exposure to certain chemicals or extreme conditions may weaken the oxide layer and make aluminum more susceptible to corrosion. Therefore, while aluminum sheets are generally resistant to chemicals, it is important to consider the specific chemical environment and potential interactions before using aluminum in certain applications.

- Q: This question asks for an explanation of the various types of paint that can be applied to aluminum sheets.

- <p>Aluminum sheets can be coated with different types of paints to enhance their appearance, durability, and functionality. The common types include: 1) Acrylic Paints: Known for their flexibility and resistance to weathering and UV rays. 2) Polyester Paints: These offer excellent adhesion and gloss. 3) Epoxy Paints: Known for their chemical resistance and durability. 4) Polyurethane Paints: They provide a tough, scratch-resistant finish. 5) Powder Coatings: These are electrostatically applied and offer a durable, weather-resistant finish. 6) Fluoropolymer Coatings: They provide excellent resistance to chemicals and UV degradation. Each type has specific properties that make it suitable for different applications and environments.</p>

- Q: Are aluminum sheets suitable for chemical processing applications?

- Yes, aluminum sheets are suitable for chemical processing applications. Aluminum is known for its excellent corrosion resistance, making it a popular choice in various chemical industries. It can withstand exposure to many chemicals, including acids, alkalis, and organic solvents. Additionally, aluminum sheets are lightweight, easy to work with, and offer good thermal conductivity, making them versatile and efficient for chemical processing applications.

- Q: I saw a guy on ebay take a washed out paint can fill it full of lighted charcoal bricks and a tin can in the middle. He was melting aluminum cans in there then pured it into a mold. Does this really work and does anyone have any good ideas on how else to do this?

- Aluminum alloys melt at around 1200 degrees, aluminum cans maybe somewhat lower, but I doubt a tin can would hold up long enough to melt much aluminum, and you would need to be very careful, any moisture in your mold will cause the aluminum to literally explode back into your face. I am not saying it couldn't be done, but you really would need lots of safety equipment before trying it.

- Q: Are aluminum sheets suitable for marine hulls?

- Indeed, marine hulls can indeed be made using aluminum sheets. The utilization of aluminum in boat construction is widespread due to its numerous advantageous properties. The lightweight nature of aluminum enables enhanced fuel efficiency and increased speed. Furthermore, its exceptional resistance to corrosion renders it well-suited for prolonged exposure to saltwater. Moreover, aluminum possesses remarkable strength and durability, thereby ensuring the integrity of the hull's structure. Additionally, aluminum can be easily manipulated into intricate shapes, allowing for the creation of innovative hull designs. In summary, aluminum sheets represent a dependable and efficient option for marine hulls, delivering a robust and corrosion-resistant framework that enhances the boat's performance and lifespan.

- Q: I don't like purchasing deoderants that contain aluminum sulfate due to the fact that a build-up of aluminum may cause Alzheimer's (my grandfather has it). So, I purchased an all natural deoderant only to later look more closely at the labely and see POTASSIUM ALUM....hmmm, alum versus aluminum? Supposedly alum cannot be absorbed by the skin so it's safe....any proof?

- Alum is easily got in India. It is used in homes where they do not have a water filter and they swirl it round in the water and in seconds you see the dirt go to the base of the vessel and all you do then is strain it. Try an Indian grocery store. It you are in London try to get it from Quality super market in Southall as they have everything imaginable Indian product.

Send your message to us

Aluminum Sheets for Semi Trailer Wall - 5 Bars Embossed Aluminum Sheet 5052 Alloy for Transportation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords