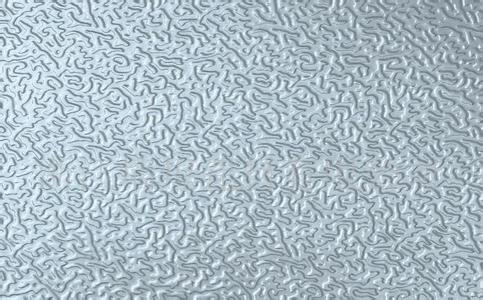

Aluminum Sheets Bunnings - Aluminium Coil Embossed Orange Peel Pattern

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Aluminum Sheet Embossed Description:

Our product is coated with high-performance fluorocarbon, polyester, polyurethane and epoxy coating, and is widely used for roofs, facade cladding, ceilings, aluminum curtains, composite panels, pipe wrap, advertisement plates, instrument panels, and other uses.

Main Features of the Aluminum Sheet Diamante Embossed:

Enviromental, light weight, waterproof, fireproof, anti-rust, weather resistance, easy cleaning, easy matching with other decoration materials...

Images of Aluminum Sheet Embossed:

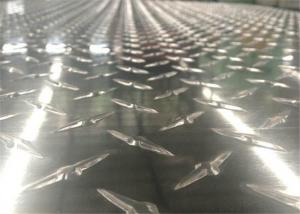

Aluminum Sheet Embossed Specification:

Other Product | Alloy | Temper | Thickness(mm) | Width (mm) | Length (mm) |

Aluminum tread plate | 1100 1050 1060 | O H12 H14 H16 H18 H22 H24 H26 H32 H36 H111 H112

| 0.2-200 | 40-1450 | As your requirement |

3003 3004 3005 3105 | |||||

5005 5754 5052 | |||||

5086 | |||||

6061 8011 |

FAQ of Aluminum Sheet Embossed:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What kind of material is wood grain aluminum sheet?

- The wood grain is sprayed, and the key is what you do. It's good to tell you which kind of material is used.

- Q: Can aluminum sheets be used for electrical connectors?

- Yes, aluminum sheets can be used for electrical connectors. Aluminum is a highly conductive material and has excellent electrical conductivity. It is commonly used in various electrical applications, including connectors. Aluminum connectors are lightweight, durable, and cost-effective compared to other materials such as copper. However, it is important to consider certain factors such as the type and size of the connection, the amount of current to be carried, and the environment in which the connectors will be used. Additionally, proper insulation and protection measures should be taken to prevent corrosion, as aluminum can be susceptible to oxidation. Overall, aluminum sheets can be a suitable choice for electrical connectors, but careful consideration of specific requirements and conditions is necessary.

- Q: how to find 0.6mm waste strake of aluminum sheet?

- Heating wire is mainly used for electrical heating, has large power consumption. But aluminum sheet’s cooling fin mainly uses steam or hot water to conduct Thermal dissipation, it needs hot water or steam boiler. Comparatively, Heating wire conducts Thermal dissipation quicker, but cools quicker after power outage. Aluminum sheet is in the opposite condition.

- Q: Are aluminum sheets suitable for food packaging?

- Yes, aluminum sheets are suitable for food packaging. Aluminum is a highly versatile and widely used material in the food industry due to its unique properties. It is lightweight, flexible, and has excellent barrier properties that protect the contents from external factors such as moisture, light, and oxygen. These properties help to maintain the freshness and quality of food products. Additionally, aluminum is resistant to corrosion and does not react with acidic or alkaline substances, ensuring that the taste and quality of the food is preserved. Furthermore, aluminum sheets can be easily shaped into different forms, making them ideal for various types of food packaging such as trays, containers, and foil wraps. Overall, aluminum sheets are a safe and effective choice for food packaging, providing durability, protection, and convenience.

- Q: Are aluminum sheets fire resistant?

- Yes, aluminum sheets are fire resistant.

- Q: What are the different methods of cutting aluminum sheet?

- Various methods exist for cutting aluminum sheet, each offering unique advantages and applications. 1. Shearing: Employing a sharp blade, shearing provides a quick and efficient process for straightforward cuts. However, it may not be suitable for complex or intricate designs. 2. Laser cutting: By utilizing a high-powered laser beam, laser cutting achieves precise and clean cuts. This method is ideal for intricate designs, allowing for detailed and accurate cuts. Additionally, laser cutting can be automated, making it suitable for large-scale production. 3. Waterjet cutting: With a high-pressure stream of water mixed with abrasive materials, waterjet cutting is versatile and capable of handling various materials and thicknesses. It produces smooth and precise cuts without generating heat, making it suitable for heat-sensitive materials. 4. Plasma cutting: Plasma cutting involves using a plasma torch to heat and melt the aluminum sheet, resulting in a cut. It is a fast and cost-effective method, particularly for thicker sheets. However, the cut may not be as clean as laser or waterjet cutting. 5. CNC milling: By employing a rotating cutting tool, known as Computer Numerical Control (CNC) milling, material is removed from the aluminum sheet to create a cut. This method offers precision and the ability to produce complex shapes and designs. It is commonly used for prototypes or small production runs. When selecting the appropriate method for cutting aluminum sheet, factors to consider include desired cut quality, design complexity, material thickness, and production volume.

- Q: Can aluminum sheets be used in cryogenic applications?

- Yes, aluminum sheets can be used in cryogenic applications. Aluminum has excellent thermal conductivity, low density, and good strength, making it suitable for use in cryogenic environments where extremely low temperatures are involved. Additionally, aluminum's resistance to corrosion and its ability to maintain its mechanical properties at cryogenic temperatures make it a popular choice for various cryogenic applications, such as in the aerospace industry and in cryogenic storage systems.

- Q: Are the aluminum sheets suitable for manufacturing aircraft interiors?

- Yes, aluminum sheets are highly suitable for manufacturing aircraft interiors. Aluminum is a lightweight and durable material that offers excellent strength-to-weight ratio, making it ideal for aviation applications. It is resistant to corrosion, easy to fabricate, and can be easily formed into various shapes and sizes required for aircraft interiors. Additionally, aluminum sheets can be treated with coatings or finishes to meet specific design and functional requirements.

- Q: Are aluminum sheets easy to clean?

- Yes, aluminum sheets are generally easy to clean due to their smooth surface and non-porous nature, allowing for easy removal of dirt, grease, and stains with regular cleaning agents.

- Q: Can aluminum sheets be anodized for improved corrosion resistance?

- Yes, aluminum sheets can be anodized to enhance their corrosion resistance. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum, making it more resistant to corrosion and increasing its durability.

Send your message to us

Aluminum Sheets Bunnings - Aluminium Coil Embossed Orange Peel Pattern

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords