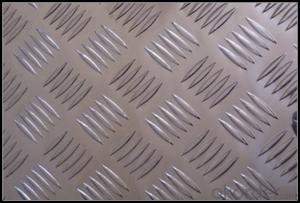

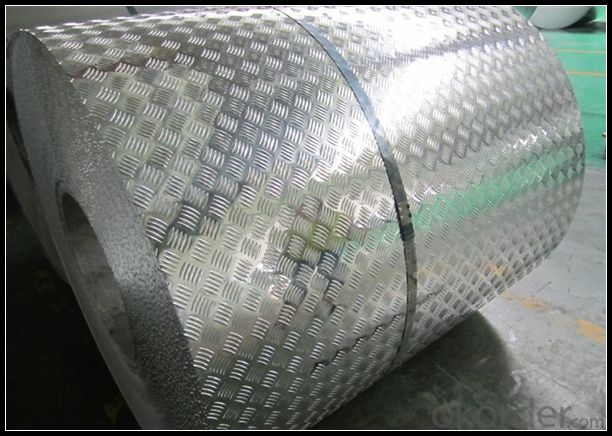

Aluminum Sheets Bahrain - Five Bars Checkered Aluminum Sheet 5005 Alloy for Transportation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Five Bars Checkered Aluminum Sheet 5005 Alloy for Transportation

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC |

TEMPER | H14,H18,H24,H26,H32 |

THICKNESS | 0.2MM-20MM |

WIDTH | 10mm-1500mm |

COIL WGT | 2Mt - 3Mt |

Coil ID | 20" |

SURFACE | Diamond, Stucco ,Bars etc |

STANDARD | GB/T 3880-2006 |

2. Application of Five Bars Checkered Aluminum Sheet 5005 Alloy for Transportation

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Five Bars Checkered Aluminum Sheet 5005 Alloy for Transportation

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

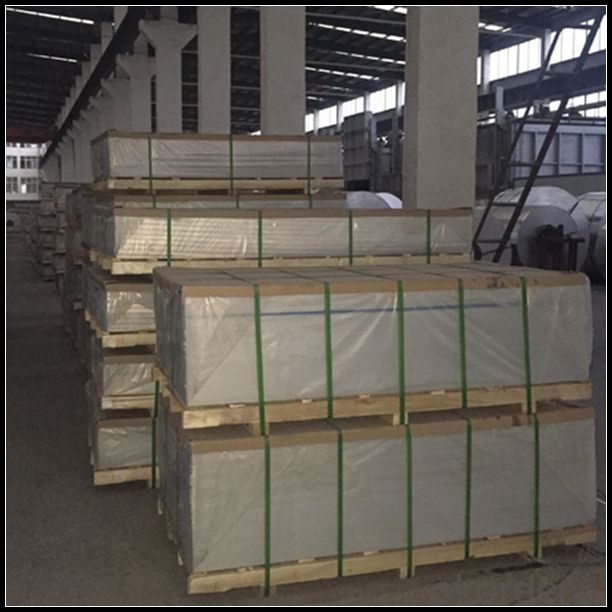

5. Image of Five Bars Checkered Aluminum Sheet 5005 Alloy for Transportation

6. Package and shipping of Five Bars Checkered Aluminum Sheet 5005 Alloy for Transportation

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: An aluminum engine block has a volume of 4.77 and a mass of 12.88 .

- Aluminum okorder /

- Q: Are aluminum sheets prone to warping?

- Yes, aluminum sheets are prone to warping, especially when exposed to high temperatures or subjected to excessive pressure. However, the extent of warping depends on various factors such as the thickness of the sheet, the specific alloy used, and the conditions it is exposed to.

- Q: I've created a sculpture out of aluminum foil, but it's pretty flimsy. What can I paint or cover it with that would harden and support it? I was thinking a resin or something, but I have no experience with resins or epoxies... Any suggestions?

- Rigid Wrap is plaster-infused gauze. You can buy it at the art supply store or at a medical supply store. The latter is cheaper. It comes on a roll so you can cut off small chunks. Wet each piece and apply it to your sculpture. The first layer may be the most difficult. I would wrap the plaster gauze around the structure so the gauze overlaps gauze. It may not stick to the aluminum but it will stick to itself. Start at the bottom and let it dry, then add another layer. As mentioned, adding too much may compromise the structure so work slowly and allow time to dry between layers.

- Q: Is the process of installing aluminum sheets considered simple or straightforward?

- <p>Aluminum sheets are generally considered easy to install, especially with the right tools and some basic knowledge of construction or home improvement. They are lightweight, which makes handling and positioning them simpler compared to heavier materials. Installation typically involves measuring, cutting the sheets to size, and attaching them to a frame or substrate using screws or adhesives. Proper alignment and securing are crucial for a professional-looking finish. For complex installations or high structures, professional assistance may be necessary to ensure safety and adherence to building codes.</p>

- Q: What are the different methods of surface coating for aluminum sheets?

- There are several methods of surface coating for aluminum sheets, including anodizing, powder coating, painting, and laminating.

- Q: Can aluminum sheets be used for packaging applications?

- Indeed, packaging applications can utilize aluminum sheets. This material, known for being lightweight, corrosion-resistant, and long-lasting, proves to be an ideal selection for packaging diverse products. It effectively shields against moisture, oxygen, and light, thus ensuring the preservation of packaged goods' quality and freshness. The malleability of aluminum sheets allows for effortless customization and branding, as they can be easily shaped into various forms and sizes. Consequently, they find widespread use in packaging food and beverages, pharmaceuticals, cosmetics, and other consumer goods. Moreover, aluminum sheets promote sustainability as they are recyclable, further enhancing their suitability for packaging purposes.

- Q: What is the atomic mass of aluminum?

- The atomic mass of aluminum is approximately 26.98 atomic mass units.

- Q: Can aluminum sheets be textured for grip?

- Indeed, grip can be achieved through texturing aluminum sheets. Numerous techniques exist to impart texture onto aluminum sheets, including embossing, etching, and the application of a non-slip coating. By undergoing these processes, patterns, grooves, or raised bumps can be added to the sheet's surface, heightening its grip and rendering it suitable for situations where slip resistance holds significance. The textured surface amplifies the friction between the sheet and any object it comes into contact with, thereby delivering a secure grip, even in damp or slippery circumstances.

- Q: What is the bending radius of aluminum sheets?

- The bending radius of aluminum sheets is influenced by several factors, including the sheet thickness, the type of aluminum alloy used, and the bending method employed. In general, aluminum sheets with a thickness of 1mm or less can be bent without cracking if the radius is equal to the thickness of the sheet. For thicker aluminum sheets, it is necessary to have a bending radius that exceeds the thickness of the sheet in order to prevent cracking or fracturing. As a rule of thumb, aluminum sheets with a thickness ranging from 1mm to 6mm should have a bending radius at least 1.5 times the sheet thickness. For instance, a 3mm thick aluminum sheet should have a minimum bending radius of 4.5mm. It is important to note that these guidelines are approximate and can vary depending on the specific aluminum alloy and temper utilized. Additionally, different bending processes, such as air bending, bottoming, or coining, may require different bending radii. To obtain precise bending radius requirements for specific applications of aluminum sheets, it is advisable to consult the manufacturer's specifications or seek professional advice.

- Q: What are the weight-saving benefits of using aluminum sheets in different applications?

- Using aluminum sheets in various applications offers several benefits for weight-saving. Firstly, aluminum is a lightweight metal with a density much lower than commonly used materials like steel. This means that by replacing steel sheets with aluminum sheets, significant weight reduction can be achieved in different applications. The reduced weight of aluminum sheets is especially advantageous in transportation industries. For instance, in the automotive sector, using aluminum sheets for body panels, chassis components, and other structural parts can significantly lighten the overall weight of vehicles. This weight reduction leads to improved fuel efficiency as it requires less energy to move the lighter vehicle. Additionally, lighter vehicles generally exhibit better acceleration, handling, and braking performance. In the aerospace industry, the weight-saving benefits of aluminum sheets are even more crucial. Every additional kilogram of weight on an aircraft can increase fuel consumption and operating costs. By utilizing lightweight aluminum sheets in the construction of aircraft structures such as wings, fuselages, and engine components, the overall weight of the aircraft can be reduced, resulting in improved fuel efficiency and extended flight range. The construction sector also highly values the weight-saving benefits of aluminum sheets. Due to their lightweight nature, aluminum sheets are often used in building and infrastructure construction. This characteristic not only makes installation easier but also reduces the load on the building's foundation. Moreover, using aluminum sheets in construction can lead to cost savings as lighter materials require less support structure and can be transported more efficiently. Furthermore, the weight-saving benefits of aluminum sheets extend to various other applications such as packaging, electronics, and consumer goods. In packaging, aluminum sheets are commonly used for lightweight and flexible packaging materials, reducing shipping costs and environmental impact. In electronics, aluminum sheets are used in devices like laptops and smartphones, where weight reduction is desirable for portability. Lastly, in consumer goods, aluminum sheets are utilized for producing lightweight and durable products such as furniture, cookware, and sports equipment. In conclusion, the weight-saving benefits of using aluminum sheets in different applications are significant. Aluminum's lightweight nature allows for weight reduction in transportation industries, improved fuel efficiency, better performance, and extended flight range in aerospace applications, cost savings, and easier installation in construction, as well as various advantages in packaging, electronics, and consumer goods. Overall, aluminum sheets provide a versatile and efficient solution for achieving weight reduction and enhancing performance in diverse industries.

Send your message to us

Aluminum Sheets Bahrain - Five Bars Checkered Aluminum Sheet 5005 Alloy for Transportation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords