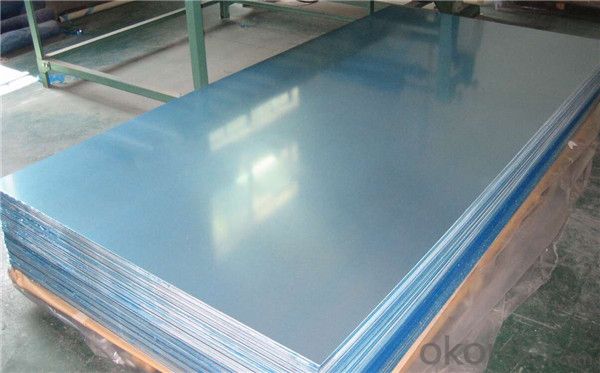

Textured Aluminum Sheets Home Depot - Aluminum Sheet with Blue Film Covered 1050 1060 1100 H14

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

Aluminum sheet checkered /Aluminum sheet embossing sheet

| Material | 1000 series: 1050. 1070. 1100 2025. 2117. 2218. 2618. 6000 series: 6005. 6011. 6053. 6351. 6061. 6101. 6151. 6201. 6261. 6262. 6063. 6463. 6066.6070 7000series: 7001. 7005. 7072. 7075. 7076. 7175. 7178. 7079 8000 series:8011,8021,8079 etc |

| Standard | GB/T17748-2008 |

| Certification | ISO9001,ISO14001, ISO9001:2000 |

| Temper | T4,T5,T6,H111,H112 |

| Surface treatment | Polished,Mill Finished,anodized or power sprayed |

| Features | High weather resistance anti scratch anticorrosion and good weather resistance subtle edges and elegant appearance and easy processing and installation high brightness and hardness |

| Resolution | 2%-98% |

| Advantages | 1)Excellent machining properties 2)Suited to marine and low temp applications |

| Note | If you have any other questin,welcome for your consultation |

1050 1060 1100 H14 Aluminum Sheet with Blue Film Covered

| alloy | 1050 1060 1100 3003 |

| temper | HO H12 H14 H24 etc |

| thickness | 0.10-6.0 mm |

| width | no limited |

| delivery term | within 25-30 days after confirming order |

| payment term | 30% by TT in advance as deposit and 70% balance by TT or L/C at sight |

| package | seaworthy strong wooden pallet or as the customer's requirements |

| surface | flat clean surface no whole, scratch, oil dirty and oxidation. |

| cutting edge | neat cutting edge no burrs. |

| remark | specific requirement of alloy, temper or specifications can be discussed in your request. |

Alloy | Thickness (mm) | Width (mm) | Length (mm) | Temper | DC or CC | |

1050,1060, 1070,1100, 1235 | 1)0.2-3.0; 2)3.0-150 | 300-1850; 900-1900 | 1000-8000 | 1)O,H12,H22, H14,H24,H26, H18,H32, 2)H112,H111; | 1)DC,CC 2)DC | |

3003,3004, 3105,3005 | 1)0.2-3.0; 2)3.0-150 | 30-1850 900-1900 | 1000-8000 | 1)O,H12,H22, H14,H24,H26, H18,H32, 2)H112,H111; | 1)DC,CC 2)DC | |

5052,5083, 5754,5005 | 1)0.2-3.0 2)3.0-150 | 300-1850 900-1900 | 1000-8000 | 1)O,H12,H22, H14,H24,H26, H18,H32, 2)H112,H111; | 1)DC 2)DC | |

6061,6063 | 0.5-3.0 | 300-1500 | 1000-6000 | T6,T321 | DC | |

6060 | 0.2-100 | 200-1500 | ≤12000mm | T4,T5,T6, H111,H112 | DC | |

| Application | 1) Home Lighting Lighting Network; 2)Solar reflective pieces; 3)architectural appearance; 4)Indoor decoration: ceiling, metope, etc 5)drying cabinet; 6)elevator; 7)scutcheon, luggage etc; 8)The car inside and outside decoration; 9) Indoor decorations, such as picture frames; 10) Household appliances: refrigerators microwave audio equipment, etc 11)Aerospace and military aspects, such as China's large aircraft manufacturing, the shenzhou spacecraft series, satellites, etc 12)Precision Parts Processing; 13)mould making; 14)Chemical/thermal insulation pipe coating etc |

Packaging & Shipping

Package: Standard seaworthy packing or as per request

Transports:Containler sizes:

20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High)

40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High)

Our Services

1 Customer and reputation first

2 Timely feedback

3 Low MOQ

4Timely delivery

5 Competitive price

6Different size can be supplyed as your request

7 Professional service of technical and shipping support

8More than 30 years experience in the cold and hot rolled sheet/coil/stri experience

Photos

- Q: Is it possible to utilize recycled aluminum to manufacture new items?

- <p>Yes, recycled aluminum can be used to create new products. Aluminum is highly recyclable, and the process of recycling it requires significantly less energy compared to producing aluminum from raw materials. Recycled aluminum maintains the same properties as new aluminum, making it suitable for a wide range of applications, from packaging to construction materials. The use of recycled aluminum helps reduce waste, conserve resources, and lower environmental impact.</p>

- Q: What are the different surface finishes for aluminum sheets in the construction industry?

- In the construction industry, there are several different surface finishes that can be applied to aluminum sheets. These finishes are designed to enhance the appearance and durability of the aluminum, making it suitable for various construction applications. One common surface finish for aluminum sheets is mill finish. This finish is the raw, untreated surface of the aluminum, which may have some minor imperfections or scratches. Mill finish is often used in applications where appearance is not a major concern, such as structural components or industrial projects. Another popular surface finish is anodized finish. Anodizing is an electrochemical process that creates a protective layer on the surface of the aluminum, making it more resistant to corrosion and wear. Anodized finishes can come in a variety of colors, allowing for greater design flexibility in construction projects. This finish is commonly used for architectural elements, such as window frames, facades, and decorative panels. Painted finishes are also commonly used in the construction industry. Aluminum sheets can be coated with a layer of paint, which provides both aesthetic appeal and additional protection against corrosion. Painted finishes can be customized to match specific design requirements, making them suitable for a wide range of construction applications. Additionally, brushed finishes are often used in the construction industry. Brushing is a mechanical process that creates a textured surface on the aluminum, resulting in a distinctive, matte appearance. This finish is commonly used for decorative purposes, such as interior wall panels or furniture in commercial spaces. In summary, the construction industry offers a variety of surface finishes for aluminum sheets. These finishes include mill finish, anodized finish, painted finish, and brushed finish. Each finish has its own unique properties and benefits, allowing for greater versatility and customization in construction projects.

- Q: What are the potential environmental issues that arise from the use of aluminum sheets?

- <p>Yes, there are environmental concerns related to using aluminum sheets. The production process is energy-intensive and contributes to greenhouse gas emissions. Additionally, the mining of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. The disposal of aluminum waste can also lead to pollution if not properly managed. However, aluminum is highly recyclable, which can mitigate some of these concerns if recycling practices are adopted widely.</p>

- Q: How to polish aluminum sheet to be bright?

- you must do some protection work, or you will fail once aluminum contacts air. Aluminum sheet is easy to be oxided and volatilized.

- Q: I need to fix some connections at my dad's house. The original wiring is aluminum, but the newer stuff he did is copper. Simple wire nuts will not suffice. Already had one melted one. I need to fix the connections, but need an economical, safe way of doing it. Suggestions?

- Replace all the wires into copper. Risk of fire as copper joints with aluminum or cause intermittent problem use on heavy current load. Because copper twists joint with aluminum create thermo effect. Aluminum wire was abandoned for house wiring long long time ago.

- Q: Are aluminum sheets suitable for thermal insulation?

- No, aluminum sheets are not suitable for thermal insulation on their own. While aluminum is a good conductor of heat and electricity, it does not have good insulating properties. In fact, aluminum sheets can actually transfer heat instead of blocking it, making them ineffective for thermal insulation purposes. For proper thermal insulation, materials with low thermal conductivity, such as fiberglass, mineral wool, or foam boards, are commonly used. These materials are designed to trap air or create a barrier that reduces the transfer of heat, ensuring effective insulation.

- Q: How does the purity of aluminum affect its properties as a sheet?

- The properties of aluminum as a sheet are significantly influenced by its purity. Increased levels of purity generally lead to improved mechanical properties, as well as enhanced thermal and electrical conductivity, and better resistance against corrosion. When aluminum possesses a high level of purity, meaning it contains minimal impurities, it becomes more malleable and ductile. This characteristic makes it easier to shape into thin sheets, rendering highly pure aluminum sheets more appropriate for applications requiring intricate shapes and designs. Moreover, the high electrical conductivity of pure aluminum makes it an exceptional choice for electrical applications, such as wiring and circuit boards. It enables efficient transmission of electricity while minimizing the risk of overheating. Additionally, the thermal conductivity of pure aluminum makes it an ideal option for heat transfer purposes. Aluminum sheets with a high level of purity can effectively dissipate heat, making them well-suited for applications like heat sinks and radiators. Furthermore, the corrosion resistance of aluminum increases with higher levels of purity. Pure aluminum forms a protective oxide layer on its surface, which serves to prevent corrosion and prolong the lifespan of aluminum sheets in various environments. In conclusion, the purity of aluminum directly impacts its properties as a sheet. Increased levels of purity enhance its mechanical properties, as well as its electrical and thermal conductivity. Additionally, it improves its resistance against corrosion, making it more versatile and suitable for a wide range of applications.

- Q: Characteristics of anodized aluminium plate

- (1) good processing: anodized aluminum decorative strong, moderate hardness, easy bending forming, continuous high-speed, convenient and direct processing into products, no need for complicated surface treatment, greatly shorten the production cycle and reduce production cost.(2) good weather resistance: standard thickness of oxide film (3 m) anodized aluminum plate, indoor use for a long time, no discoloration, no corrosion, no oxidation, no rust. Anodized aluminum oxide film (10 m) can be used outdoors, and can be exposed to sunlight for a long time without discoloration.

- Q: If you're familiar with some of my previous questions, you'll know I have a thing for DC-3's, and I'd like to buy one and fix it up at some point in my life. I was looking at pictures on Google for my desktop background and saw several with shiny chrome/aluminum bodies. Well, first of all, is it chrome or polished aluminum? Second, would I be able to buy a DC-3 painted this God-awful forest green and put whatever it is (chrome/aluminum) on said plane? Or is it something that the plane has to be built with originally?

- The shine comes from alclad aluminum. The aluminum sheeting of the aircraft actually has about .004 of pure aluminum coating . That pure aluminum is how they get the chrome like shine.

- Q: Can aluminum sheets be plasma cut?

- Indeed, aluminum sheets are able to undergo plasma cutting. The technique of plasma cutting presents itself as a versatile and highly effective method capable of cutting various materials, including aluminum, with great efficiency. By utilizing a high-speed stream of ionized gas, commonly referred to as plasma, the aluminum sheet can be meticulously shaped and tailored to meet specific requirements. Plasma cutting boasts a multitude of advantages, such as faster cutting speeds, more precise cuts, and significantly reduced heat-affected zones, in contrast to traditional cutting methods. As a result, it has become a widely utilized technique in numerous industries, including automotive, aerospace, and construction, for the purpose of cutting aluminum sheets of varying thicknesses.

Send your message to us

Textured Aluminum Sheets Home Depot - Aluminum Sheet with Blue Film Covered 1050 1060 1100 H14

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords