Aluminum Sheet Coil Price - Aluminum Circle AA1100 H14 from China Famous Company

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Thickness | 0.1mm-8mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm |

Width | 20mm-2500mm |

inner diameter | 76mm / 152mm |

Material | AA1050, AA1060, AA1070, AA1100, AA1235, AA3003, AA3004, AA3005, AA5052, AA5005, AA5754, AA5083, AA8011, AA8079, etc |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38, |

Surface | Mill finish / Coated |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 30-35 days after the receiving L/C or deposit |

2. Application of

(1) Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors, windows,

(2) Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations.

(3).Advertisement: display platforms, signboards, fascia, shop fronts.

3. Feature of

Aluminum sheet specifications:

1) Alloy : 1050 1060 1070 1100 2024 3003 3004 3105 3A21 5005 5052 5083 5754 5182 5454 5456 6061 6063 7075 8011 etc

2) Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.1mm to 300mm

4) Width:20mm to 3300mm

5)Length: ≤ 12000mm

6) Protective film can be added

7) Production Line: DC and CC production line

4. Certificate:

SGS and ROHS (if clients request, paid by client), MTC (plant provided), Certificate of Origin (FORM A, FORM E, CO), Bureau Veritas (if client request, paid by client), CIQS certificate and so on.

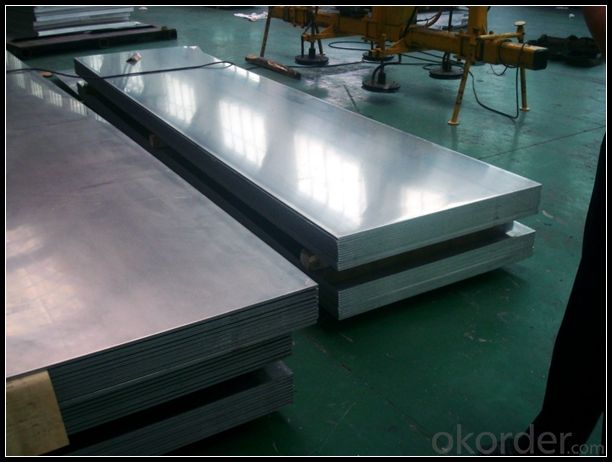

5. Image of Aluminum sheets

6. Package and shipping of

Eye to wall

Eye to the wall

With wooden pallet (wooden case also available)

7. FAQ

1) What is the delivery time?

Depends on actual order, around 30 to 35 days

2) What is the QC system?

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are there any limitations on the surface treatment of aluminum coils?

- The surface treatment of aluminum coils has certain limitations. One limitation pertains to the type of surface treatment suitable for aluminum coils. Anodizing, painting, and powder coating are some options for surface finishes. However, not all treatments are suitable for every application. For instance, anodizing is a durable and corrosion-resistant finish but may not meet the requirements of applications that demand specific colors or designs. Similarly, painting and powder coating offer a wide range of colors and aesthetics but may not match the durability of anodizing. Another limitation concerns the size and shape of the aluminum coils. Surface treatment processes have size and shape restrictions for aluminum coils. For example, anodizing is typically performed in tanks or racks, which may have size limitations. Similarly, painting and powder coating processes may require specific equipment or facilities that cannot accommodate large or irregularly shaped coils. Furthermore, the condition of the aluminum surface affects the effectiveness of the surface treatment. Imperfections or surface defects on aluminum coils can impact the adhesion and durability of the treatment. Proper cleaning and preparation of the aluminum surface are crucial to ensure the effectiveness of the surface treatment. In conclusion, while there are various surface treatments available for aluminum coils, limitations exist regarding the type of treatment, the size and shape of the coils, and the condition of the aluminum surface. It is important to consider these limitations and select the most suitable surface treatment based on the specific requirements and constraints of the application.

- Q: What are the potential applications of coil-perforated aluminum coils?

- Coil-perforated aluminum coils have a wide range of potential applications due to their unique properties and capabilities. Some of the potential applications of these coils are: 1. Architectural Applications: Coil-perforated aluminum coils can be used in architectural projects for facades, cladding, and sunscreens. The perforations allow for the creation of decorative patterns and designs, while also providing functional benefits such as ventilation and light control. 2. Industrial Applications: These coils can be used in various industrial applications such as filtration systems, soundproofing panels, and heat exchangers. The perforations in the aluminum coils allow for the passage of air, sound, and heat, making them suitable for these purposes. 3. Automotive Industry: Coil-perforated aluminum coils can be utilized in the automotive industry for applications such as radiator grilles, speaker covers, and air vents. The perforations in the coils provide functional benefits like airflow, sound transmission, and aesthetic appeal. 4. HVAC Systems: These coils can be employed in heating, ventilation, and air conditioning (HVAC) systems. The perforations in the aluminum coils allow for improved airflow, which helps in efficient temperature regulation and air distribution within buildings. 5. Acoustic Panels: Coil-perforated aluminum coils can be used in the construction of acoustic panels, which are designed to absorb and reduce sound reflections in spaces like auditoriums, theaters, and recording studios. The perforations in the coils aid in sound absorption and diffusion. 6. Lighting Fixtures: These coils can be incorporated into lighting fixtures to create unique lighting effects. The perforations in the aluminum coils allow light to pass through, resulting in visually appealing patterns and designs. 7. Furniture and Decorative Applications: Coil-perforated aluminum coils can be utilized in the manufacturing of furniture, screens, partitions, and decorative elements. The perforations in the coils add a distinctive aesthetic appeal and can create interesting visual effects. Overall, the potential applications of coil-perforated aluminum coils are diverse and encompass various industries, including architecture, automotive, industrial, HVAC, acoustic, lighting, and furniture. The unique properties of these coils, such as their lightweight, durability, and aesthetic customization options, make them a versatile choice for many different uses.

- Q: What are the different coil packaging sizes available for aluminum coils?

- The different coil packaging sizes available for aluminum coils vary depending on the manufacturer and industry requirements. Common coil packaging sizes for aluminum coils range from small coils with diameters as small as 150mm to larger coils with diameters exceeding 1000mm. The coil widths can also vary, typically ranging from 100mm to 1500mm. However, it is important to note that specific coil packaging sizes may differ based on customer specifications and the intended application of the aluminum coils.

- Q: What is the tensile strength of aluminum coils?

- The tensile strength of aluminum coils can vary depending on the specific alloy and temper used. However, on average, aluminum coils have a tensile strength ranging from 150 to 300 megapascals (MPa). This means that aluminum coils can withstand a pulling force of 150 to 300 MPa before breaking or deforming. It is important to note that the tensile strength may be influenced by factors such as the thickness of the coil, the manufacturing process, and any additional treatments or coatings applied to the aluminum.

- Q: Can aluminum coils be used in the production of solar reflectors?

- Certainly! Solar reflectors can utilize aluminum coils in their production. Due to its exceptional reflectivity and durability, aluminum is widely employed in the manufacturing of these reflectors. The coils can be manipulated and molded into the desired shape for the reflector, facilitating efficient sunlight reflection onto the solar panels. Furthermore, aluminum's lightweight nature simplifies its handling and installation in solar reflector systems.

- Q: Are aluminum coils suitable for signage applications?

- Yes, aluminum coils are suitable for signage applications. Aluminum is a highly versatile material that offers several advantages for signage purposes. Firstly, aluminum coils are lightweight, making them easy to handle and install. This is particularly beneficial for large outdoor signs or banners that need to be mounted or hung. Additionally, aluminum is highly resistant to corrosion, ensuring that the signage will remain in good condition even in harsh weather conditions. This durability also makes aluminum coils suitable for long-term outdoor use, as they can withstand exposure to UV rays, moisture, and temperature changes without deteriorating. Furthermore, aluminum coils can be easily fabricated and shaped to create various sign designs, including flat panels, channel letters, and dimensional signage. They can be painted or coated with different finishes to achieve the desired aesthetic appearance, making them versatile for branding and marketing purposes. Another advantage of using aluminum coils for signage applications is their recyclability. Aluminum is a sustainable material that can be recycled repeatedly without losing its quality. This makes it an environmentally-friendly choice for businesses that prioritize sustainability and want to reduce their carbon footprint. In summary, aluminum coils are a suitable choice for signage applications due to their lightweight nature, corrosion resistance, durability, versatility in design, and recyclability.

- Q: What are the potential challenges in recycling aluminum coils?

- Recycling aluminum coils presents several potential challenges that need to be addressed. To begin with, the removal of contaminants such as paint, oil, or other coatings from aluminum coils is a crucial step before the recycling process can commence. This task can be both time-consuming and costly as it requires thorough cleaning to ensure the quality of the recycled aluminum. Furthermore, the presence of mixed materials like steel or plastic in aluminum coils complicates the recycling process even further. These materials must be separated from the aluminum before it can be melted down and recycled. This separation necessitates specialized equipment and expertise, thereby increasing the cost and complexity of recycling aluminum coils. Transportation and logistics also pose a significant challenge in recycling aluminum coils. Their large and heavy nature makes it challenging and expensive to transport them to recycling facilities. Additionally, these facilities must possess suitable infrastructure to handle and process the coils efficiently. Moreover, the fluctuating market prices of aluminum contribute to the challenges in recycling aluminum coils. The value of recycled aluminum is influenced by global supply and demand, which can vary greatly over time. This unpredictability makes it difficult for recyclers to accurately predict the financial returns from recycling aluminum coils, potentially impacting the viability of the recycling process. Lastly, the overall awareness and participation in aluminum coil recycling present a challenge. Many industries and individuals may lack awareness regarding the benefits of recycling aluminum coils or may not have access to recycling facilities. Overcoming this challenge requires increasing education and improving accessibility to recycling programs, thereby promoting the sustainable recycling of aluminum coils.

- Q: Can aluminum coils be used in high-pressure applications?

- No, aluminum coils are not typically used in high-pressure applications due to their lower strength and less resistance to deformation compared to other materials such as steel.

- Q: Can aluminum coils be used in the production of aluminum cladding?

- Yes, aluminum coils can be used in the production of aluminum cladding.

- Q: why is aluminum used for railway lines?thanks x

- Aluminum is strong ans light weight.

Send your message to us

Aluminum Sheet Coil Price - Aluminum Circle AA1100 H14 from China Famous Company

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords