Aluminum Extrusion Profiles 80/20 - Aluminum Sheet, Plate, Slab, and Other Grades Tempers

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

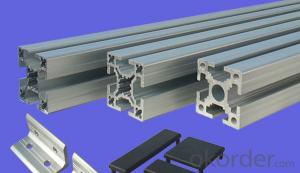

1.Structure of Product Description

Cold rolled and hot rolled and cold drawn and hot drawn aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22,O,FO,H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1000*1000,500*500,800*800,900*700mm,

1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Can aluminum profiles be used in curtain wall systems?

- Yes, aluminum profiles can be used in curtain wall systems. Curtain wall systems are typically made of lightweight materials that provide structural support while allowing maximum natural light into a building. Aluminum is a popular choice for curtain wall systems due to its strength, durability, and versatility. It offers excellent resistance to corrosion, making it suitable for outdoor applications. Additionally, aluminum profiles can be easily fabricated into various shapes and sizes, allowing for flexibility in design and assembly. The lightweight nature of aluminum also makes installation easier and more cost-effective. Overall, aluminum profiles provide an ideal solution for curtain wall systems, delivering both aesthetic appeal and functional performance.

- Q: What are the aluminum profile markets in Cangzhou, Renqiu?

- They all answered, "I tell you, ah, play, huh?"Choose me as the best, hey!

- Q: This question asks for a comparison between aluminum profiles and other materials commonly used for roofing, focusing on their characteristics and performance.

- <p>Aluminum profiles for roofing are known for their durability, corrosion resistance, and lightweight nature. Compared to materials like steel, they are less prone to rust and offer a longer lifespan with minimal maintenance. When compared to traditional materials like wood or clay tiles, aluminum profiles are more resistant to weathering and do not rot or warp. They also have a high strength-to-weight ratio, making them ideal for structures that require lighter roofing materials. Additionally, aluminum profiles can be easily recycled, contributing to sustainability efforts. However, they may not offer the same aesthetic appeal as traditional materials and can be more expensive upfront.</p>

- Q: Are aluminum profiles resistant to mold or mildew?

- Yes, aluminum profiles are resistant to mold and mildew. The inherent properties of aluminum make it highly resistant to the growth of mold and mildew. Unlike other materials such as wood, which can be susceptible to moisture damage and thus promote the growth of mold and mildew, aluminum is not prone to these issues. Additionally, aluminum profiles are often treated with protective coatings or finishes that further enhance their resistance to mold and mildew. This makes aluminum profiles a suitable choice for areas that are prone to high humidity or moisture, such as bathrooms or kitchens, where the growth of mold and mildew is a common concern.

- Q: The latest list of aluminum China

- Lear aluminum is also good Oh, A Well-Known Trademark in China, China energy-saving innovation enterprise ten, Hebei enterprises in Handan

- Q: This question asks for a comparison between aluminum profiles and other materials used in constructing frames, focusing on their characteristics and performance.

- <p>Aluminum profiles are favored for building frames due to their high strength-to-weight ratio, making them lightweight yet durable. They offer excellent corrosion resistance, which is superior to materials like steel, which can rust. Aluminum profiles are also easy to machine and form, allowing for complex designs. Compared to wood, they are more resistant to weathering and pests. However, they may not have the same aesthetic appeal as wood or the thermal insulation properties of some plastics. Overall, aluminum profiles are a strong choice for structural integrity and longevity in frame construction.</p>

- Q: How is the price of aluminum profile calculated?

- The price is in accordance with the composition of aluminum ingot price plus processing fees in the form of the aluminum price is according to the informed price this is the South China Sea, the Internet can be found on the aluminum ingot prices every day is not the same, Saturday Sunday is not the price of aluminum ingot processing, to look at the cost of the products, aluminum price + welding rod cost the processing cost is + aluminum prices, profile surface treatment is not the same, the price is not the same

- Q: Are aluminum profiles suitable for use in the renewable energy industry?

- Yes, aluminum profiles are suitable for use in the renewable energy industry. Aluminum is a versatile and lightweight material that offers several advantages for renewable energy applications. Firstly, aluminum profiles have excellent corrosion resistance, making them suitable for use in outdoor environments where they may be exposed to moisture or harsh weather conditions. This durability ensures that the profiles can withstand the test of time and maintain their structural integrity. Furthermore, aluminum profiles are highly recyclable, making them an environmentally friendly choice for the renewable energy industry. As the industry strives to reduce its carbon footprint and promote sustainability, the recyclability of aluminum helps in achieving these goals. Aluminum can be recycled repeatedly without losing its essential properties, which reduces the need for extracting and processing new raw materials. Aluminum profiles also offer design flexibility, allowing for the creation of complex shapes and structures that can be customized to meet specific requirements. This versatility makes them suitable for various renewable energy applications, such as solar panel frames, wind turbine components, and mounting systems. Additionally, the lightweight nature of aluminum profiles simplifies transportation and installation processes, reducing costs and energy consumption. In summary, aluminum profiles are an excellent choice for the renewable energy industry due to their corrosion resistance, recyclability, design flexibility, and lightweight properties. These attributes contribute to the overall efficiency, durability, and sustainability of renewable energy systems, making aluminum profiles a suitable material for use in this industry.

- Q: Are aluminum profiles suitable for use in exterior wall insulation systems?

- <p>Yes, aluminum profiles can be used for exterior wall insulation systems. They are known for their durability, resistance to corrosion, and ability to withstand various weather conditions. Aluminum profiles provide a strong structural framework that can support insulation materials effectively. They are also lightweight, which makes them easy to handle and install. Additionally, aluminum profiles can be anodized or coated to enhance their resistance to environmental factors, making them a popular choice for exterior insulation systems.</p>

- Q: This question asks about the various methods for connecting aluminum profiles using fasteners.

- <p>There are several ways to join aluminum profiles together using fasteners: 1. Bolts and Nuts: Commonly used for strong and removable connections. 2. Rivets: Provide a permanent connection, suitable for high-stress applications. 3. Screws: Offer a secure and adjustable connection, often used in furniture and construction. 4. Pins: Used for alignment and positioning, often in lighter applications. 5. Adhesives: Can be used for a more aesthetically pleasing joint, though not as strong as mechanical fasteners. 6. Welding: Although not a fastener method, it is a common way to join aluminum profiles for a permanent and strong bond. Each method has its advantages and is chosen based on the specific requirements of the application, such as strength, permanence, and ease of assembly.</p>

Send your message to us

Aluminum Extrusion Profiles 80/20 - Aluminum Sheet, Plate, Slab, and Other Grades Tempers

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords