Aluminum Sheets Wyoming - Aluminum Oxide Discs, Metal Disks, Aluminum Plates

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Other | Min.A1 | |

5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | - | 0.1 | - | - | - | 0.2 | Remain |

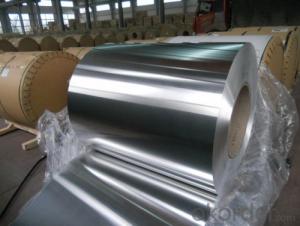

The Details of 5052 Aluminum disc:

5052 Aluminum disc adopts high-tech machinery utilizing premium grade Aluminium Coil. Customized according to the needs and demands of the clients these can be availed at different technical specifications.

5052 Aluminum disc Surface:Bright & smooth surface, free from defects like white rust, oil patch, edge damage.

5052 Aluminum disc Application: 5052 Aluminium disc are used in Reflective Sign Boards, Road Furniture, Utensils, Sand witch Bottom, Cooker, Non-Stick etc.

The Properties of 5052 Aluminum disc:

1.Alloy 1050 1060 1100 1200 3003 3004 3105 5052 5005 5754 aluminium disc, deep drawing quality, good spinning quality, excellent forming and anodizing, no four ears.

2.Excellent reflectivity, good for Polishing.

3.Good anodized quality, suitable for hard anodizing and enameling.

4.Clean surface and smooth edge, hot rolled quality, fine grains and after deep drawing no looper lines.

5.Excellent pearl color anodizing.

Why we choose Okorder.com?

Okorder.com is a professional and reliable online E-market place

Providing a variety of products with reasonable prices

High quality goods provided by factory suppliers

Shipping to over 200 countries.

One-stop sourcing

Dubai Logistic Complex

Okorder Quality Control?

We hold a very strict quality control system to check every connector of our products for your safety.

Okorder services for you

1.7*24 hours Hotline & Email Service

2. Your inquiry related to our products or prices will be replied in 24hrs.

3. Well-trained and experienced staffs to answer all your enquires in fluent English

4. OEM&ODM, any your customized demand we can help you to design and put into product.

5. Distributor ship are offered for your unique design and some our current models

- Q: I'm 17 and it has been very hard finding a deodorant that makes me stop sweating. I told my dad I wanted to get Ban or Mitchum cause the percentage of Aluminum is very high. He said the Aluminum in deodorant has links to alzheimers, is that true? Also my sister said I could just scrub with soap morning and night, use regular deodorant without antipersperant and that would make me stop sweating too. But since i'm a teenager and my hormones are still weird would that be strong enough to stop sweat?

- aluminum oxide in antipersperant does lead to alzheimer's, yes. but antiperspirant is not deodorant, and deodorant does not contain aluminum. sweating is a natural bodily function. if you need to sweat, sweat. it's odor that should bother people.

- Q: Is it possible to use aluminum sheets as a material for flooring?

- <p>Yes, aluminum sheets can be used for flooring applications. They are known for their durability, resistance to corrosion, and ease of maintenance, making them suitable for various environments. Aluminum flooring is often used in commercial, industrial, and residential settings due to its strength and lightweight nature. It can be found in applications such as walkways, ramps, and as a covering for platforms. However, it's important to note that aluminum may not be the best choice for all flooring needs, especially where thermal insulation or a softer, warmer feel is desired.</p>

- Q: This question asks if aluminum sheets are appropriate for use in regions with cold temperatures.

- <p>Aluminum sheets are generally suitable for use in cold climates. They have excellent resistance to corrosion and maintain their structural integrity in low temperatures. However, aluminum is a good conductor of heat, so it can be prone to heat loss if not properly insulated. For outdoor applications in cold climates, it's important to ensure that aluminum structures are well-insulated to prevent heat transfer. Additionally, aluminum's malleability can make it susceptible to denting or damage from ice and snow, so protective measures may be necessary.</p>

- Q: What are the potential health risks associated with handling aluminum sheets?

- <p>Working with aluminum sheets can pose certain health concerns, primarily due to inhalation of aluminum dust or fumes. Long-term exposure may lead to respiratory issues and potentially neurological problems. Aluminum dust can cause irritation to the eyes, nose, and throat. In some cases, it may contribute to the development of Alzheimer's disease, although this link is still debated. It's important to follow safety guidelines, such as using proper ventilation and wearing protective gear like masks and gloves, to minimize these risks.</p>

- Q: which kind of abraser should be used for deburring of aluminum sheet?

- you can use soft resin grinding stone.

- Q: I am looking for info on grades of aluminum like 3003, 5053, 6160 what's the differance witch one are cheaper and weld easy please explain

- Aluminum rims are a whole lot better on the mechanical stand point, they are lighter, usually stronger (depending on the alloy) and they allow for better heat disapation. Lighter rims will save gas money (nothing you will notice, maybe an extra mile/tank, if that). Depending on the alloy used in the aluminum rims, they are usually stronger and can take more froce abuse, just as long as they don't get scuffed up, ect. With the better heat disapation. When the brakes heat up, the heat is sent out ever direction, mostly through metal. Aluminum (alloy) is a great conductor of heat.

- Q: Wonderland is the hard aluminum with what tools do? Thank you

- Wrought iron platform made 3 aluminum alloy with a hard aluminumAluminum + granite can also be synthesized

- Q: Are aluminum sheets suitable for chemical processing?

- Aluminum sheets, indeed, prove to be fitting for chemical processing. Renowned for its superb resistance to corrosion, aluminum has gained popularity as a preferred option for tasks involving exposure to diverse chemicals. It develops a shielding oxide layer that halts further corrosion, even in demanding surroundings. Additionally, aluminum's lightweight characteristic facilitates its handling and transportation within the chemical processing sectors. Furthermore, aluminum excels as a heat conductor, enabling efficient temperature regulation during chemical reactions. All in all, when considering their corrosion resistance, lightweight composition, and commendable thermal conductivity, aluminum sheets emerge as a prudent selection for chemical processing endeavors.

- Q: Are the aluminum sheets corrosion-resistant?

- Yes, aluminum sheets are corrosion-resistant.

- Q: Can aluminum sheets be used for chemical reactors?

- Certain applications allow for the use of aluminum sheets in chemical reactors. Aluminum possesses excellent corrosion resistance, rendering it appropriate for diverse chemical reactions. Nevertheless, it is crucial to take into account the nature of the chemicals employed and their potential reactivity with aluminum. In highly acidic or alkaline environments, aluminum's reactivity and susceptibility to corrosion should be duly recognized. Furthermore, specific gases or elevated temperatures may render aluminum unsuitable for reactions. In such instances, alternative materials such as stainless steel or glass-lined reactors might prove more fitting.

Send your message to us

Aluminum Sheets Wyoming - Aluminum Oxide Discs, Metal Disks, Aluminum Plates

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords