Aluminum Pipes for Building Material Aluminum Profile

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are the largest aluminum profilemanufacture in

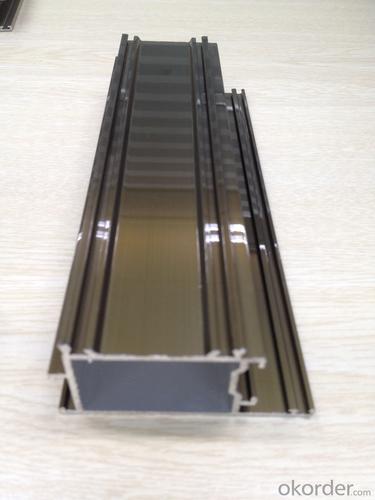

Material | Alloy Aluminum 6063,6061,6005,6082 or customer nominated |

Temper | T3, T4, T5, T6 and other |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Not more than 16 meters |

Good Package | Inner plastic film /outside carton/wooden pallets |

Payment Method | T/T, L/C, etc |

Delivery Time | Normally 2-4 weeks, Delivery time can be consulted. |

Press Machine | 500-12500 tons all together 93 press lines. |

Fabrication | 1. Furniture;2. Drilling; 3. Bending; 4. Cutting; 5. Windows and doors;6.etc. |

Certificate | ISO/TS 16949,DNV,IRIS,CCS,AFA,etc. |

Dies | 1. Using our dies, no fee; |

2. Using customer drawing, opening dies, usually about 5~50 tons then the dies cost can be refunded. | |

3. Die cost is negotiable base on the order quantity | |

Capability | Annual output 800,000 tons |

- Q: Are aluminum pipes affected by exposure to industrial solvents?

- Yes, aluminum pipes can be affected by exposure to industrial solvents. Aluminum is generally resistant to many chemicals, but certain solvents can cause corrosion or deterioration of the metal over time. It is important to select the appropriate type of aluminum alloy and protective coatings to minimize the potential damage caused by exposure to industrial solvents. Regular maintenance and inspections are also crucial to ensure the longevity and performance of aluminum pipes in such environments.

- Q: Can aluminum pipes be welded?

- Yes, aluminum pipes can be welded.

- Q: Can 304 stainless steel aluminum pipe be welded with 6061?

- 304 stainless steel tube 6061 aluminum tubes, dissimilar metal welding.Method for welding friction welding, stainless steel tubes are respectively fixed on the friction welding of two fixed chuck open welder for rotation, two workpiece contact surface friction heat, through the pressurizing the two dissimilar metal contact oxidation layer is damaged, is to continue to operate a two joint welding effect metal.

- Q: Is the Haier refrigerator a copper tube or an aluminum tube?

- The evaporator aluminum tubes used to corrosion perforation, pipe junction and easy desoldering, perforated is not easy to repair.

- Q: Are aluminum pipes suitable for wastewater treatment facilities?

- Yes, aluminum pipes are suitable for wastewater treatment facilities. Aluminum is a durable and corrosion-resistant material, which makes it a suitable choice for numerous applications, including wastewater treatment. It is particularly useful in environments where the pipes are exposed to chemicals or corrosive substances found in wastewater. Aluminum pipes are lightweight, making them easy to install and handle during maintenance or repair work. Additionally, aluminum has a high strength-to-weight ratio, which means it can withstand high pressure and stress without compromising its structural integrity. Overall, aluminum pipes offer several advantages for wastewater treatment facilities, making them a suitable choice for this application.

- Q: What is the cost of aluminum pipes compared to other materials?

- The cost of aluminum pipes can vary depending on various factors such as the size, thickness, and grade of the pipe, as well as the current market conditions. However, generally speaking, aluminum pipes tend to be more affordable compared to other materials such as stainless steel or copper. Aluminum is a lightweight material that is easily accessible and abundant, which helps to keep its production costs relatively lower. Additionally, aluminum pipes do not require as much energy or resources to manufacture compared to other metals, contributing to their lower cost. On the other hand, materials like stainless steel or copper are generally more expensive due to their higher production costs and limited availability. Stainless steel pipes, for example, require additional alloying elements and complex manufacturing processes, which increase their price. Copper pipes, known for their excellent heat conductivity, are also more expensive due to the higher cost of copper as a raw material. It is important to note that the specific cost comparison between aluminum pipes and other materials may vary depending on the market conditions and specific project requirements. Therefore, it is advisable to consult with suppliers or conduct thorough research to get accurate pricing information for the desired materials.

- Q: How do aluminum pipes perform in salty environments?

- Due to their innate resistance to corrosion, aluminum pipes exhibit excellent performance in salty environments. Unlike other metals, aluminum develops a protective oxide layer upon exposure to air, serving as a shield against saltwater. This oxide layer effectively hinders corrosion and mitigates the impact of saltwater on the pipes. Nevertheless, it is crucial to acknowledge that extended exposure to concentrated saltwater may eventually result in some corrosion. Hence, it is advisable to conduct routine maintenance and inspections to guarantee the durability of aluminum pipes in salty environments.

- Q: Can aluminum pipes be used for roller coaster constructions?

- Indeed, roller coaster constructions can incorporate aluminum pipes. Aluminum, being both lightweight and sturdy, proves to be an ideal material for fabricating the structural framework of roller coasters. Its attributes include resistance to corrosion, durability, and simplicity in fabrication, offering a multitude of advantages. Moreover, the high strength-to-weight ratio of aluminum aids in minimizing the roller coaster's total weight, resulting in increased velocity and smoother rides. The malleability of aluminum additionally permits intricate designs and precise engineering. Consequently, aluminum pipes have become a favored option for constructing roller coasters in the amusement park sector.

- Q: Can aluminum pipes be used for airport terminals?

- Yes, aluminum pipes can be used for airport terminals. Aluminum is a popular material choice for various applications in airport terminals due to its numerous advantages. Firstly, aluminum is lightweight, which makes it easier to handle during construction and installation. This can lead to cost savings and faster project completion times. Additionally, aluminum pipes are corrosion-resistant, which is crucial in environments like airport terminals where exposure to moisture, humidity, and chemicals is common. This resistance to corrosion ensures the longevity and durability of the pipes, reducing maintenance and replacement costs in the long run. Another advantage of using aluminum pipes in airport terminals is their excellent thermal conductivity. Aluminum pipes can efficiently transfer heat, making them suitable for applications such as heating, ventilation, and air conditioning (HVAC) systems. This property can contribute to energy efficiency and cost savings for the terminal's operations. Furthermore, aluminum is a sustainable material as it is easily recyclable. This aligns with the increasing emphasis on environmental responsibility in modern construction practices. By using aluminum pipes, airport terminals can contribute to sustainable building practices and reduce their carbon footprint. In summary, aluminum pipes can be effectively used in airport terminals due to their lightweight nature, corrosion resistance, thermal conductivity, and sustainability. Considering these advantages, it is a suitable material choice for various applications within airport terminal infrastructure.

- Q: Can aluminum pipes be used for gas transportation?

- Yes, aluminum pipes can be used for gas transportation. Aluminum is a lightweight and corrosion-resistant material, making it suitable for safely transporting various gases.

Send your message to us

Aluminum Pipes for Building Material Aluminum Profile

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords