Aluminum Pallet Aluminum Pipes

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 sets set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are the largest aluminum profilemanufacture in

Please see more info as belows:

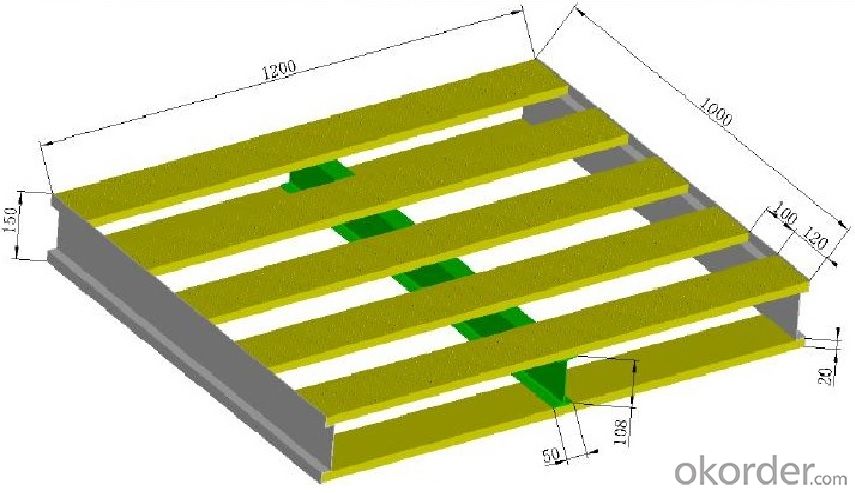

No. | Dimension(mm) | Weight(kg) | Alloy | Dynamic load | Static load | Load mode | Processing type |

1 | 1200×1000×153 | 14.84 | AL6061-T6 | 1.5t | 3t | Single side | Welding |

2 | 1200×1000×150 | 14.38 | AL6061-T6 | 1.5t | 3t | Single side | Welding |

3 | 1200×1000×150 | 21.56 | AL6061-T6 | 1.5t | 3t | Double side | Welding |

4 | 1200×800×150 | 11.90 | AL6061-T6 | 1.5t | 3t | Single side | Welding |

5 | 1200×800×150 | 17.62 | AL6061-T6 | 1.5t | 3t | Double side | Welding |

6 | 1100×1100×150 | 14.39 | AL6061-T6 | 1.5t | 3t | Single side | Welding |

7 | 1100×1100×150 | 20.96 | AL6061-T6 | 1.5t | 3t | Double side | Welding |

8 | 1200×1000×150 | 14.13 | AL6061-T6 | 1.5t | 3t | Single side | Riveting |

9 | 1200×1000×150 | 18.60 | AL6061-T6 | 1.5t | 3t | Double side | Riveting |

- Q: How can copper tubes be plated?

- According to the principle of the electrolytic cell, it can be completed! Do this: aluminum cathode of a power supply, a bobbin is connected with the anode, in the aluminum sulfate solution, can be completed! You can check to prevent accidents. Thank you for your attention

- Q: Is the tube of LED lamp all plastic tube well or half plastic half aluminium tube?

- Of course, the power is placed inside the aluminum tube, so that the amount of LED heating plus the heating capacity of the power supply is considerable, because the power of this lamp is usually around 20W. If the power is bigger, half of the aluminum tube can not solve its heat dissipation problem. It also proposed another aluminum tube cooling fan: shaped tubes. The fan shaped aluminum frame with heat dissipation structure shape, greatly increasing the radiator area. It puts the power outside the tube so that the half of the aluminum shell is completely made into a radiator. Relative to the semicircular aluminum tube, its heat dissipation area has increased by more than 3 times. Coupled with the power does not put in the tube, but also to reduce heat, which greatly extended the life of LED.

- Q: Can aluminum pipes withstand high wind loads?

- Yes, aluminum pipes can withstand high wind loads. Aluminum is known for its strength-to-weight ratio, making it an ideal material for various applications, including structural elements. Aluminum pipes are commonly used in construction, particularly for outdoor structures such as flagpoles, antennas, and support frames. They have excellent resistance to wind loads due to their high tensile strength and corrosion resistance. Additionally, aluminum pipes can be designed and fabricated to meet specific load requirements, ensuring their ability to withstand high winds.

- Q: How do I remove the aluminum from the PPR steady state aluminum tube?

- Hello, PPR steady pipe has a special tool called stripper. It is specially used to remove the aluminum layer on the steady pipe. I hope I can help my friend

- Q: I am now a lot of goods, some can be folded, and some directly broken, and this is how it happened?

- As a rule, T5 can not be bent. If you want to fold it, you need to heat it and then fold it.O or H status can be bent

- Q: What is the difference between the aluminum tube connection and the copper tube connection of the air conditioner?

- Links are used almost, but the effect of the. Copper is high cost, good ductility, resistance to oxidation, bellbottom do good pressure resistance, not easy leakage of refrigerant, disadvantage is high cost, use for a long time will be aging hard aluminum biggest advantage is cheap, and good bending and bending resistance than copper, we all know that when we installed air conditioning, pipeline is often there is no need to bend the copper tube bending resistance, the cooling effect will not be affected, but the disadvantage is that the pressure difference can not do bell, not resistant to oxidation, it is prone to leak, if not good insulation cotton, it is a hidden danger. Now the beautiful GREE is using copper tubes.

- Q: Shenzhen Jin Rongfa metal materials Co., Ltd., specializing in processing aluminum tubes, aluminum bars, aluminum plate, aluminum processing, oxidation, a variety of anodic oxidation. Sand blast oxidation. Hard anodized, colors, black, blue, red, tyrant gold, rose goldLathe kits and laser marking processing are also provided!

- 1., a wide range of applications: laser marking machine can be marked on almost all materials. 2., marking efficiency is high: laser marking machine is controlled by the computer, the laser beam can move at high speed, the marking process can be completed in a few seconds, online marking can be achieved. 3., marking precision is high: laser can form very thin beam, in the material surface of the most fine wire width of up to microns, can print all kinds of graphics, trademarks, bar codes, two dimensional code. Laser marking can also improve the appearance, image and brand effect of products, and enhance the market competition ability of products. 4., the use of low cost: laser marking is non-contact marking, not subject to the usual mold marking fatigue service life limit. Maintenance costs are very low in batch processing.

- Q: Are aluminum pipes suitable for pharmaceutical storage?

- Yes, aluminum pipes are suitable for pharmaceutical storage. Aluminum is a lightweight and durable material that is resistant to corrosion, making it an ideal choice for storing pharmaceutical products. It is also non-toxic and does not react with most medications, ensuring the integrity and safety of the stored drugs. Additionally, aluminum pipes can be easily cleaned and sterilized, which is crucial for maintaining the hygiene and quality of pharmaceutical products. Overall, aluminum pipes provide a reliable and efficient solution for pharmaceutical storage needs.

- Q: A sewage pH=5, containing a small amount of NaCl and sodium sulfate, from the corrosion point of view should be used iron tube, aluminum tube or ceramic pipe?

- Acid waterThere are sodium particles in the waterIron pipes and sodium pipes are corrodedCeramic pipes should be used

- Q: Can aluminum pipes be used for electrical conduits?

- Yes, aluminum pipes can be used for electrical conduits. Aluminum is a lightweight and corrosion-resistant material, making it suitable for various applications, including electrical systems. Aluminum conduits are commonly used in industrial and commercial settings due to their durability and cost-effectiveness. However, it is important to note that aluminum is a good conductor of electricity, so proper insulation and grounding are necessary to ensure safety. Additionally, it is advisable to consult local building codes and regulations to ensure compliance with specific requirements for electrical conduit materials.

Send your message to us

Aluminum Pallet Aluminum Pipes

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 sets set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords