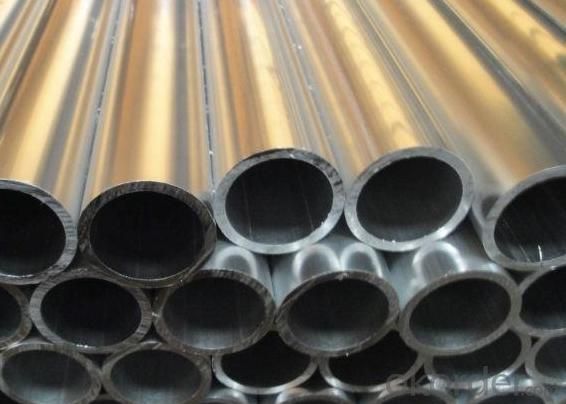

Aluminum Pipes 1060

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Pipe 1060:

1.Specifications of aluminium pipe 1060:

1)Alloy:1060;

2)Wall thickness : 0.4mm-80mm ;

3)Outer diameter : 10-900mm ;

4)Length : 6m-9m.

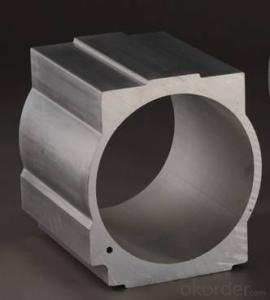

2.Application of aluminium pipe 1060:

aluminum window, door, curtain wall, hand railing, normal aluminum profile, decorative and industrial aluminum profile

3.Features of aluminium pipe 1060:

High weather resistance anti scratch anticorrosion and good weather resistance subtle edges and elegant appearance and easy processing and installation high brightness and hardness.

4.Packaging:

protection foam heat contracted plastic film,Wooden packing , Metal pallet

- Q: Which refrigerator, evaporator, aluminum tube?

- As far as I know, the freezer of the Haier three direct cold refrigerator is an aluminum tube, which you can see directly

- Q: Are aluminum pipes suitable for chemical refineries?

- Yes, aluminum pipes are generally not suitable for chemical refineries due to their reactivity with various chemicals, potential corrosion, and lower strength compared to other materials like stainless steel or carbon steel which are commonly used in such environments.

- Q: Can aluminum pipes be bent or shaped?

- Yes, aluminum pipes can be bent or shaped using various methods such as heat bending, cold bending, or using specialized pipe bending machines.

- Q: Are aluminum pipes suitable for irrigation systems?

- Indeed, aluminum pipes prove to be a fitting choice for irrigation systems. Aluminum, being a lightweight and durable material, displays resistance to corrosion, rendering it an exceptional option for irrigation systems. It possesses the ability to endure high water pressure and is less prone to cracking or breaking, unlike PVC or steel pipes. Furthermore, aluminum pipes provide flexibility and simplicity in installation, as they can be effortlessly cut and connected. Additionally, aluminum pipes boast an extended lifespan and necessitate minimal maintenance, thus being a cost-effective alternative for irrigation systems. On the whole, aluminum pipes emerge as a dependable and efficient selection for irrigating agricultural fields, gardens, and landscapes.

- Q: What is the chemical composition of aluminum pipes?

- Aluminum pipes are primarily composed of aluminum, which is a chemical element with the symbol Al and atomic number 13. Aluminum is a lightweight and versatile metal known for its corrosion resistance, high thermal conductivity, and excellent strength-to-weight ratio. It is commonly alloyed with other elements to enhance its properties. Some common alloying elements used in aluminum pipes include copper, silicon, magnesium, and zinc. These alloying elements can improve the strength, hardness, and machinability of the aluminum pipe. The specific chemical composition of aluminum pipes can vary depending on the desired properties and application requirements.

- Q: The aluminum pipe joint on the unit is broken. Take a look at it. There is a copper ring on the aluminum tube. I don't know how it was pressed. Do you know any friend here? What equipment do you need to press up? Do you have any manual equipment? A friend who knows is better illustrated with a picture. Thank youThank you friends reply, but you're wrong, the copper ring is pressed up and see what this is the copper ring on both sides of the copper ring is a device pressure to take off the copper ring in the aluminum tube plays the role of sealing

- Sold together, the nut is cracked Cut off the copper ring and replace it with a copper ring and nutGeneral pneumatic tools or hydraulic parts are sold at the storeI've used it.

- Q: What are the different grades of aluminum used in pipes?

- There are several different grades of aluminum that are commonly used in pipes, each with their own unique properties and applications. Some of the most commonly used grades include: 1. 6061-T6: This is a widely used grade of aluminum alloy that offers excellent strength and corrosion resistance. It is commonly used in structural applications, such as pipe frames and supports, as well as in the aerospace industry. 2. 6063-T6: This grade of aluminum is known for its good formability, making it ideal for extrusion processes used in pipe manufacturing. It has good corrosion resistance and is often used in architectural applications, such as handrails and decorative pipe work. 3. 5086-H32: This grade of aluminum is specifically designed for marine applications, as it offers high corrosion resistance in saltwater environments. It is commonly used in the construction of boat hulls, ship structures, and offshore platforms. 4. 3003-H14: This grade of aluminum is known for its excellent weldability and formability. It is often used in the manufacturing of pipes for HVAC systems, as well as for general piping applications where corrosion resistance is required. 5. 7075-T6: This is a high-strength grade of aluminum that is primarily used in aerospace and military applications. It has excellent fatigue resistance and is often used in the construction of aircraft frames and high-performance pipes. It is important to note that the choice of grade will depend on the specific requirements of the pipe application, such as strength, corrosion resistance, and formability. Consulting with a materials engineer or pipe manufacturer can help determine the most suitable grade of aluminum for a particular project.

- Q: Can aluminum pipes be used for swimming pool systems?

- Yes, aluminum pipes can be used for swimming pool systems. Aluminum is a popular choice for pool systems due to its durability, resistance to corrosion, and lightweight nature. It is commonly used for piping, especially in areas with high moisture or corrosive conditions, making it a suitable option for swimming pool systems.

- Q: Are aluminum pipes suitable for pharmaceutical manufacturing?

- Aluminum pipes indeed possess the potential to be appropriate for pharmaceutical manufacturing. Thanks to its manifold advantageous properties, aluminum stands as a frequently employed material in the pharmaceutical sector. Being lightweight, resistant to corrosion, and easily sterilizable, it emerges as an ideal choice for situations where cleanliness and hygiene hold utmost importance. Furthermore, aluminum pipes offer the convenience of malleability, enabling the creation of diverse shapes and sizes, thereby facilitating the design of pharmaceutical equipment. Nonetheless, one must bear in mind that certain medications or substances could potentially react with aluminum. Thus, it is crucial to carry out compatibility tests to ascertain the suitability of aluminum pipes for specific pharmaceutical manufacturing processes.

- Q: resulting in the pipe can not be used after folding, how to deal with? Fifteen08 years to buy three AUX air-conditioning, moving this year, the pipe was folded, and then installed, AUX said after the sale of the pipe can not be used, to replace all new, because the aluminum pipe can not be welded. We all know that the tube is very expensive, then bought 5 meters or so, I think it will not have to spend money again, I did not expect, because of this reason, even for old pipes, the installation of new tubes, but also spend nearly 1000 yuan. When I bought it, I didn't think they would use the aluminum tube. I thought it was copper. It was entirely cost saving by the factory, which made the consumer pay the bill. I was so angry that I didn't buy anything from AUX any more. Would you like to ask if you have ever touched this situation? What can you do to reuse the old pipes?

- You only have to spend this money, or who help you install.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 2006 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Nanhai Port |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Pipes 1060

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords