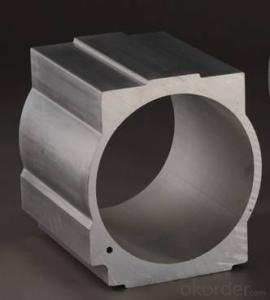

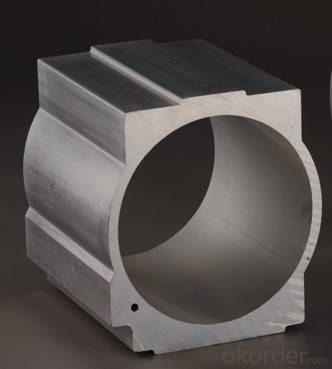

Aluminum Pipe Air Cylinder Shell

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are the largest aluminum profilemanufacture in

Material | Alloy Aluminum 6063,6061,6005,6082 or customer nominated |

Temper | T3, T4, T5, T6 and other |

Surface | Anodize, Mill,rtc |

Colour | Mill |

Length | -- |

Good Package | Inner plastic film /outside carton/wooden pallets |

Payment Method | T/T, L/C, etc |

Delivery Time | Normally 2-4 weeks, Delivery time can be consulted. |

Press Machine | 500-12500 tons all together 93 press lines. |

Fabrication | 1. Air cylinder shell; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO/TS 16949,DNV,IRIS,CCS,AFA,etc. |

Dies | 1. Using our dies, no fee; |

2. Using customer drawing, opening dies, usually about 5~50 tons then the dies cost can be refunded. | |

3. Die cost is negotiable base on the order quantity | |

Capability | Annual output 800,000 tons |

- Q: Are aluminum pipes recyclable?

- Yes, aluminum pipes are recyclable.

- Q: Can aluminum pipes be anodized?

- Yes, aluminum pipes can be anodized. Anodizing is a process that creates a protective oxide layer on the surface of aluminum, improving its corrosion resistance and enhancing its appearance.

- Q: Does GREE have aluminium tubes?

- The original pipe is all copper tube, but the extension should pay attention to guard against immoral, installation work secretly lengthen the aluminum tube

- Q: Can anodized aluminum 6061-T6 surface be oxidized?

- The so-called T6 is a kind of heat treatment, the main process is rolling solid solution and aging, these steps is to let the inner Aluminum Alloy changed, the metal can reach high strength and long deformation, anodic oxidation of our workpiece can have better conductivity and not the impurity content of workpiece the 6061 is too high, a low impurity content of his aluminum alloy aluminum is much less than, so the conductivity of aluminum has good ductility and high anodic oxidation and chemical polishing, is a good choice.

- Q: How do aluminum pipes perform in seismic zones?

- Aluminum pipes have shown good performance in seismic zones due to their inherent characteristics of being lightweight and flexible. These properties allow them to absorb and dissipate seismic energy, reducing the risk of structural damage or failure. Additionally, aluminum pipes have high ductility, enabling them to withstand ground movements during earthquakes without experiencing significant deformation or rupture. Overall, aluminum pipes are considered a reliable choice for use in seismic zones.

- Q: Are aluminum pipes suitable for paper mills?

- Yes, aluminum pipes are suitable for paper mills. Aluminum is highly resistant to corrosion and can withstand the harsh chemicals and high temperatures often found in paper mills. Additionally, aluminum pipes are lightweight, making them easy to install and maintain in the industrial setting of paper mills.

- Q: What's the difference between the 7075 aluminum tube and the 6063 aluminum tube?

- There are also minor differences: 7075 corrosion resistance than 6063, in use should pay attention to. Welding performance is poor.Other differences are generally not to be considered.

- Q: What are the different threading options for aluminum pipes?

- Depending on the specific application and requirements, there are various threading options available for aluminum pipes. Some commonly used threading options for aluminum pipes include the following: 1. In plumbing applications, NPT (National Pipe Thread) threads are widely utilized. These threads have a tapered design and are suitable for low-pressure applications. They offer a tight seal and are easy to assemble and disassemble. 2. NPTF (National Pipe Thread Fuel) threads are similar to NPT threads but have a modified thread form that ensures a better seal. These threads are commonly employed in applications where a leak-proof connection is crucial. 3. In Europe and other countries, BSP (British Standard Pipe) threads are commonly used. They have a parallel design and are available in two types: BSP parallel and BSP tapered. These threads are often used in industrial applications and can be sealed using thread sealant or tape. 4. UNF (Unified National Fine) threads are finer than their coarse counterparts (UNC) and provide a more precise fit. These threads are frequently used in applications that require a higher degree of precision. 5. Metric threads are widely used in countries that follow the metric system. They come in various sizes and pitches and are often found in automotive, aerospace, and other industries. When selecting the threading option for aluminum pipes, it is crucial to consider the specific requirements of the application, such as pressure, temperature, and compatibility with other components. Seeking advice from a professional or referring to industry standards can help determine the most suitable threading option for a particular application.

- Q: Can aluminum pipes be used for building facades?

- Yes, aluminum pipes can be used for building facades. Aluminum is a highly versatile and durable material that is commonly used in construction due to its lightweight nature, corrosion resistance, and ease of installation. Aluminum pipes can be customized to various sizes and shapes, making them suitable for different architectural designs. Additionally, aluminum can be finished with different coatings or finishes to enhance its aesthetic appeal and protect it from environmental factors. Overall, aluminum pipes are a popular choice for building facades as they offer a balance between functionality, durability, and design flexibility.

- Q: Are aluminum pipes resistant to saltwater corrosion?

- Yes, aluminum pipes are generally resistant to saltwater corrosion.

Send your message to us

Aluminum Pipe Air Cylinder Shell

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords