Aluminum Sheets in Wisconsin - Aluminium Coated or Plain Diamond Sheets for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Coated or Plain Diamond Sheets Used for Decoration Description:

Color coated aluminium foil combines all advantages of modern coil-coating technology in our full-automatic production line. Our modern production is 4 coated in one with digital precision control, we can created pattern like Wood, stone, graphic as you want. The aluminium substrate gets degreased, chemically pre-treated and coated in a single production step which resulting in a high-quality uniform coatingreproducible at any time and a material which has been developed for easy processing for a variety of application.

2.Main Features of Aluminium Coated or Plain Diamond Sheets Used for Decoration:

-High temperature resistant

-Weathering resistant

-Scrubbing resistant

-Sound insulation

-Acid or alkali proof

-Fireproof

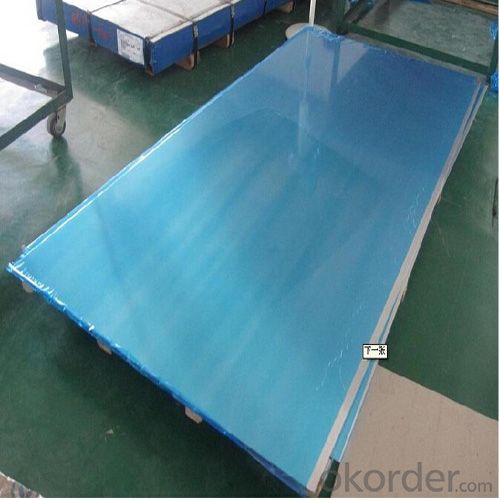

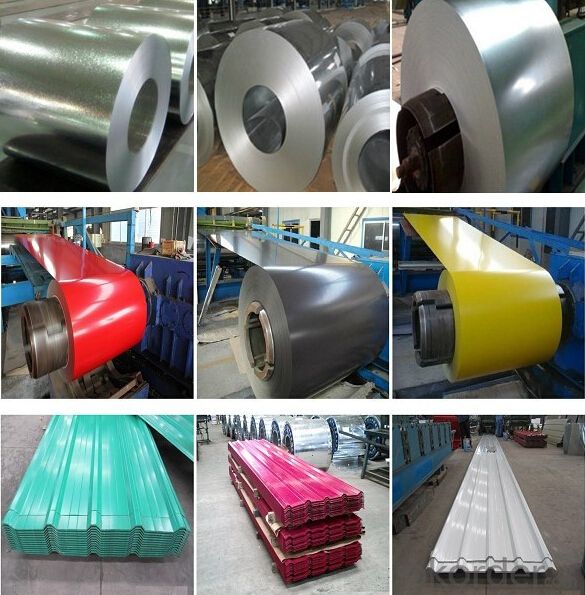

3. Aluminium Coated or Plain Diamond Sheets Used for Decoration Images:

4. Embossed Internal Color Coting Aluminium Plate Specification:

| Alloy | A1100, A3003, A3004, A5052, A5182 etc |

| Temper | O--H112 |

| Thickness | From 0.022mm to 1.5mm |

| Width | From 18mm to 2000mm |

| Diameter | Standard dia:1200mm |

| Interior dia:150mm,405mm,505mm,508mm | |

| Weight | ≤3.0 T/coil |

| Coating | PE, PVDF |

| Surface | Embossed, mill finish, coated |

| Color | Ral code or as client request |

| Gloss | 5-100% |

| Coating Thickness | PE: more than 18 micron |

| PVDF: more than 25 micron | |

| Coating Hardness (pencil resistance) | ≥H |

| Coating adhesion | 5J |

| Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

| Flexibility (T-bend) | ≤2T |

| MEK resistance | More than 100 |

| Boiling water resistance | ≥2h |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: How many molecules are in 1 square foot of aluminum foil?

- Since aluminum foil is an amalgamation of various metals you would first need to know the full chemical breakdown in order to determine how many molecules there are in a square foot of aluminum foil. That said, if your foil was 100% aluminum, you could determine the number of AL atoms by first determining the mass of the foil and dividing by the molecular weight of AL. Multiply that by 6.022 x 10^23 to determine the number of atoms.

- Q: Can aluminum sheet be used for electrical bus bars?

- Certainly, electrical bus bars can indeed utilize aluminum sheet. Aluminum is widely employed in electrical applications because of its exceptional conductivity and cost-effectiveness. Its electrical conductivity is high, comparable to copper, enabling it to effectively carry significant currents. Moreover, aluminum is lightweight and exhibits commendable resistance against corrosion, rendering it a favored option for bus bars in specific applications. Nevertheless, it is crucial to carefully evaluate the electrical system's specific requirements and standards before opting for aluminum sheet as bus bars.

- Q: Explain the distinction between aluminum sheets based on their thickness.

- <p>Aluminum sheets with different thicknesses primarily differ in their strength, weight, and applications. Thicker sheets offer greater strength and rigidity, making them suitable for structural applications or heavy-duty uses. In contrast, thinner sheets are lighter and more flexible, ideal for applications requiring formability or where weight is a concern, such as in the automotive or aerospace industries. The choice of thickness depends on the specific requirements of the project, including load-bearing needs, durability, and aesthetic considerations.</p>

- Q: Are aluminum sheets suitable for hydraulic applications?

- Indeed, aluminum sheets prove to be fitting for hydraulic applications. Being both lightweight and resistant to corrosion, aluminum serves as a remarkable option for hydraulic systems. Its commendable thermal conductivity aids in effectively dispersing heat produced during hydraulic operations. Furthermore, aluminum sheets can be effortlessly shaped and machined to fulfill precise design needs, rendering them adaptable for an array of hydraulic components including reservoirs, tanks, and piping systems. Nevertheless, it is crucial to bear in mind the pressure and temperature prerequisites of the hydraulic application, given that aluminum possesses inferior strength and melting point in comparison to metals like steel.

- Q: Could two pieces of aluminum sheets be welded together?

- or you can use file to rub back and forth, and it needs lots of practices or you can't weld the sheets.because aluminum sheet cann't be tightly welded to tin, it's hard to weld two pieces of aluminum sheets by common welding methods.it's hard, the aluminum sheets are oxidized soon after polished by abrasive paper.and you need to cover the new polished area with soldering paste and learn some operating skills.owing to aluminum sheets' high oxidized speed, you need to wipe the aluminum sheets with soldering paste and soldering tin and rub them with large power soldering iron, then the aluminum sheets will be tightly welded to tin.so two pieces of aluminum sheets could be welded together.

- Q: What is the thickness range of aluminum sheets?

- The thickness range of aluminum sheets can vary depending on the specific application and industry standards. However, commonly available aluminum sheets typically range in thickness from 0.006 inches (0.15mm) to 0.25 inches (6.35mm). For more specialized applications, thicker aluminum sheets may be available. It is important to note that different alloys and grades of aluminum may have different thickness ranges, so it is essential to consult the specific requirements and standards of the intended use case.

- Q: In which autocomponents usage of aluminium is better or otherwise?

- Aluminium is lighter as well as stronger than CI. Thats the reason most of the Automobile manufacturers use Aluminium for car bodies while they use cast iron for the underframes and internal chassis....NMN

- Q: Are aluminum sheets suitable for mold making?

- Indeed, aluminum sheets prove to be a fitting option for mold making. Renowned for its lightweight nature, durability, and remarkable heat conductivity, aluminum emerges as a favored material for mold creation. These remarkable attributes render it suitable for molding processes, whether they involve low temperatures or high temperatures. Furthermore, aluminum lends itself well to machining and can be effortlessly shaped into intricate forms, enabling the production of elaborate molds. Its resistance to corrosion further guarantees the molds' durability. In essence, owing to their adaptability and dependability, aluminum sheets enjoy extensive employment in the realm of mold making.

- Q: This question asks for methods to preserve an aluminum window and prevent rust or corrosion.

- <p>To maintain an aluminum window and prevent rusting or corrosion, follow these steps: Regularly clean the window with a mild detergent and water to remove dirt and grime. Avoid using abrasive cleaners or tools that could scratch the surface. Apply a protective coating or sealant designed for aluminum to shield it from moisture and environmental factors. Ensure proper drainage around the window to prevent water accumulation. Regularly inspect the window for signs of damage or corrosion and address any issues promptly. By following these maintenance practices, you can prolong the life of your aluminum window and keep it in good condition.</p>

- Q: What are the safety precautions when working with aluminum sheet?

- When working with aluminum sheet, it is important to take certain safety precautions. These include wearing personal protective equipment such as gloves, safety glasses, and a dust mask to protect against potential hazards. It is also advisable to work in a well-ventilated area to avoid inhaling any fumes or dust particles. Additionally, using appropriate tools and machinery specifically designed for handling aluminum sheets is essential to prevent accidents or injuries. Finally, proper handling and storage of aluminum sheets, ensuring they are stacked securely and avoiding any sharp edges, can help minimize the risk of accidents or damage.

Send your message to us

Aluminum Sheets in Wisconsin - Aluminium Coated or Plain Diamond Sheets for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords