Aluminum Mesh Sheets for Construction:Aluminium Material Sheets and Plates

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Material Sheet and Plate for Construction Description:

We can produce aluminum sheet,color aluminum sheet and plastic composite panel base material. They are widely used in construction and decoration, hardware and electric appliances manufacture, automobile manufacture and other industrial and civil purposes, such as electronic capacitor, rice cooker, refrigerator, computer casting, lamp shade, air-conditioner, cosmetics cover and box, air-conditioner radiator, inner container of disinfecting cabinet, ceiling board, automobile motherboard, cover board and top board, etc.

2.Main Features of Aluminium Material Sheet and Plate for Construction :

Totaly free from defects like white rust

Free from coil set

High Quality

Competitive Price

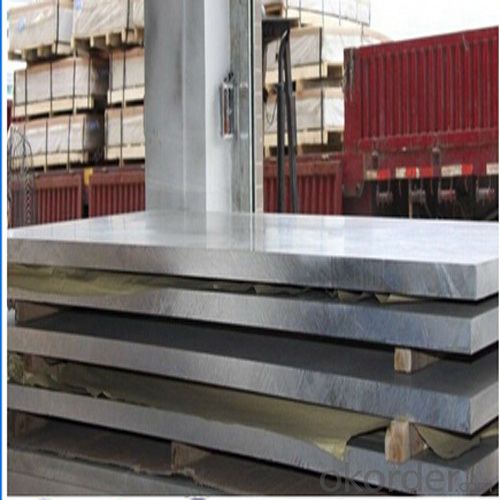

3. Aluminium Material Sheet and Plate for Construction Images:

4. Aluminium Material Sheet and Plate for Construction Specification:

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: What specific considerations or precautions should be taken into account when using aluminum sheets in environments with high moisture levels?

- <p>When using aluminum sheets in damp or wet environments, it's important to consider the potential for corrosion. While aluminum is generally corrosion-resistant due to its protective oxide layer, it can still be susceptible to certain types of corrosion in the presence of moisture, especially if the environment is acidic or saline. It's crucial to use high-quality aluminum alloys that are designed for such conditions. Additionally, proper surface treatment such as anodizing or applying protective coatings can enhance resistance to corrosion. Regular inspections and maintenance are also recommended to check for signs of corrosion and to address any issues promptly.</p>

- Q: What the glue of L solidified aluminum and fast acrylic plate, solid glue?

- Aluminum and acrylic adhesive, if you want to achieve high strength without any effect, can be bonded with KD-5603 trace glue, but this should be with the help of UV curing light curing, if there is no UV curing light, the sun is strong weather, stick in the sun after 30 minutes can be the bonding effect of glass panel; the specific effects can refer to the general glass coffee table with four Aluminum Alloy column, don't see any traces of adhesive;If you only need sticky sticks and low marks, you can choose N-906AB glue or KD-855 quick drying metal glue

- Q: What are the different fabrication methods used for aluminum sheets?

- Some of the different fabrication methods used for aluminum sheets include rolling, extrusion, casting, and stamping.

- Q: Are aluminum sheets resistant to impact?

- Yes, aluminum sheets are generally resistant to impact. Aluminum is a lightweight metal that has high strength and toughness, making it capable of withstanding impact forces. It has excellent energy absorption properties, which means it can absorb and dissipate the energy generated by an impact, minimizing damage to the sheet. Additionally, aluminum sheets can be further strengthened through various processes such as heat treatment or alloying, making them even more resistant to impact. However, the impact resistance of aluminum sheets can vary depending on the specific alloy and thickness used.

- Q: Can the aluminum sheets be used in the construction industry?

- Certainly, the construction industry can make effective use of aluminum sheets. Aluminum proves to be a highly adaptable and lightweight material, offering numerous advantages for construction purposes. Its resistance to corrosion makes it especially suitable for outdoor structures and buildings. Roofing, siding, window frames, doors, and other architectural components often incorporate aluminum sheets. Moreover, aluminum's exceptional strength-to-weight ratio enables the creation of sturdy and efficient structures. Its malleability also facilitates easy fabrication and shaping into various forms, allowing for imaginative and groundbreaking designs in construction projects. Overall, aluminum sheets remain a widely favored choice in the construction industry due to their enduring nature, adaptability, and aesthetic appeal.

- Q: What are the different types of alloys used for powder-coated aluminum sheets?

- There are various types of alloys used for powder-coated aluminum sheets, including 3003, 5052, and 6061.

- Q: Are the aluminum sheets suitable for manufacturing kitchen backsplashes?

- Indeed, kitchen backsplashes can be manufactured using aluminum sheets. Aluminum, being a lightweight and durable material, has commendable resistance against corrosion and heat. Moreover, it is effortlessly cleaned and maintained, making it highly suitable for kitchen usage where splatters and spills are prevalent. The versatility of aluminum sheets allows them to be easily cut and shaped to fit any kitchen size and design, providing ample flexibility in creating personalized backsplashes. Furthermore, aluminum contributes a modern and sleek aesthetic, thus imparting a contemporary touch to the kitchen decor. All in all, opting for aluminum sheets as a manufacturing material for kitchen backsplashes is both practical and stylish.

- Q: Can aluminum sheets be used for heat exchangers?

- Indeed, heat exchangers can utilize aluminum sheets. Aluminum, known for its remarkable heat conductivity, proves to be a perfect choice when it comes to heat exchangers. Its superior thermal conductivity facilitates exceptional heat transfer between fluids, leading to efficient heat exchange. Moreover, aluminum sheets possess the advantages of being lightweight, resistant to corrosion, and exhibiting commendable mechanical properties. These additional attributes further enhance their suitability for various heat exchanger applications.

- Q: What is the difference between the alloy 1060H24 aluminum plate and the alloy 1100H24 aluminum plate?

- The difference between the two is very small, 1060 and 1100 are 1 pure aluminum plate, H24 aluminum sheet, that is, the degree of hardness!Specific differences are as follows:Series: 1000 series aluminum alloy represents the 1050, 1060 and 1100 series.

- Q: Can aluminum sheet be used for automotive heat shields?

- Indeed, aluminum sheet is a suitable option when it comes to automotive heat shields. The automotive industry favors aluminum due to its impressive thermal conductivity and remarkable heat resistance. By reflecting and dispersing heat away from specific regions, it effectively safeguards delicate components from excessive temperatures. Moreover, aluminum possesses the advantages of being lightweight and resistant to corrosion, rendering it an optimal choice for automotive purposes. It finds widespread utilization in diverse heat shield configurations, encompassing exhaust, engine, and under-carriage heat shields.

Send your message to us

Aluminum Mesh Sheets for Construction:Aluminium Material Sheets and Plates

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords