aluminum honeycomb panels and sandwich panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 88 m²

- Supply Capability:

- 888888888 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum honeycomb panel:

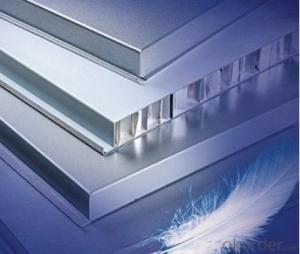

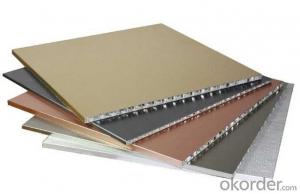

Aluminum honeycomb panels using the "sandwich" structure, surface treatment of aluminum alloy sheet fluorocarbon roll, the middle is in line with the National Aeronautics and aluminum honeycomb core standards. From Germany to introduce the use of sandwich boards for the production process --- continuous hot technology, chip technology hot, room temperature composite technology, specializing in the production of such products. So that the product has a more pronounced excellent properties, are widely used in building walls and interior decoration。

Material:

The main panel 3003 h24 series of magnesium alloy or magnesium alloy 5052 h24 series aluminum base material, 0.7 1.0 mm fluorocarbon roller plate thickness of the panel, the plate thickness of 0.5 1.0 mm, general choice 10 to 25 mm thickness. Use 3003 h24 hexagonal honeycomb core sandwich core material, the thickness of aluminum foil 0.04 0.06 mm, can fully meet the design and production needs of custom aluminum honeycomb core.

Aluminum honeycomb panel features:

★ high strength.

★ stiffness.

★ light weight.

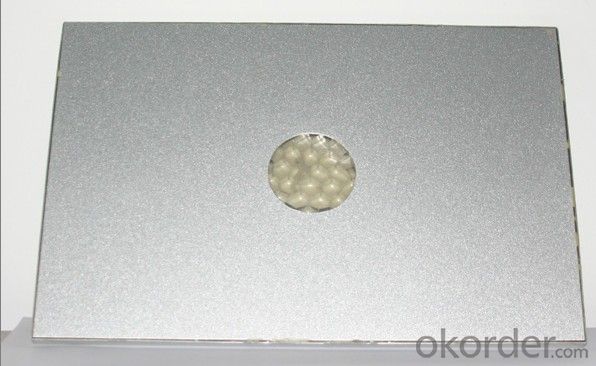

★ good surface flatness.

★ fire performance is good: B1 level.

★ noise effects: air sound insulation 29dB.

★ good insulation: thermal conductivity 0.1613W / (m.k).

★ surface using paint roller coating technology: 70% of fluorocarbon paint, weathering wall, with self-cleaning capability.

★ aluminum honeycomb panels have good temperature resistance: when used in different geographical environment -40 ℃ to + 80 ℃, according to special requirements, can reach 100 ℃.

★ environmental protection, aluminum honeycomb panels without separation or classification can be completely recycled.

Aluminum h oneycomb panel product application areas:

Buildings and structures: roofs, facades and wall cladding, ceiling / partition / door, interior {walls, floors}

Elevator: bridge car negatives, siding, roof

Exhibition, display: exhibitions, display card production, store decoration

Transportation: commercial vehicles [envelope, car bottom], ship bilge {version} bulkhead, rail, rail vehicles {negatives, siding} public, special transport vehicles {container volume, transport trough}, aircraft industry

Aluminum honeycomb Specifications:

Thickness: 6mm-560mm

Al thick: 0.5-2.5mm

Width: 800 ~ 1700mm

Length: any length

Color: do special color

Core: aluminum honeycomb core 3003H19 or 5052

Coating: fluorocarbon coating

Workshop Photos

- Q: OKorder Wang Teng color steel production and sales of a variety of color steel plate, Caigang tiles, Caigang rock wool sandwich panels, Caigang polyurethane sandwich panels, Caigang foam sandwich panels, Caigang extruded sandwich panels, color Steel paper honeycomb sandwich panels, galvanized sheet, floor board, Caigang sandwich panels, C steel, color steel activities, and other products.

- Energy-saving insulation: thermal insulation superior performance, the same thickness of the insulation effect is 2 times the EPS board. ? Flame retardant: The product has passed the "National Fixed Fire Extinguishing System and Refractory Component Quality Supervision Center", the combustion level to GB8624 B2 level standards. ? Sound insulation: sound absorption is good, on the rain, hail and other impact caused by the sound has a subtractive effect. ? Waterproof rust: a large span, fast drainage, waterproof effect is good; screw hidden, easy to rust, to extend the useful life of the plate. ? Beautiful economy: beautiful appearance, rich colors; reduce material loss, save construction time and project costs. ? Construction of fast: polyurethane sheet is a highly controlled plant in the factory environment, the quality of production, quality and stability; construction fast, the application has more than 35 years.

- Q: Paper honeycomb sandwich panels about how much the price

- Do not know what you do with, I see you most recently has been consulting honeycomb board problems, I do pp honeycomb board

- Q: What are the quality standards for color steel sandwich panels?

- Reference to national standards: GBT_23932-2009_ Building metal surface insulation sandwich panels. Color steel: sandwich board English name: color steel laminboard, the product is composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the composition of the polymer core insulation. These sandwich panels are easy to install, lightweight and efficient.

- Q: What are the types of metal wool wool sandwich panels?

- Unwinding, forming, cutting, compound processing

- Q: 100 thick rock wool sandwich panels (1.1 meters from the purlin) can do the roof? Floor thickness 0.8, panel thickness 1, so feasible?

- It is recommended to use pressure plate, flat or defective.

- Q: Rock wool sandwich panels and polyurethane sandwich panels which high fire rating

- 1, rockwool board high fire rating high. 2, rock wool sandwich board is made of rock wool as the raw material of the sandwich board. Yanmian sandwich panels give full play to the unique performance of rockwool core material, in the fire, heat insulation, sound insulation and other aspects of a significant effect. 3, polyurethane sandwich panels beautiful appearance, the overall effect is good, it sets load, insulation, fire, waterproof in one, and no secondary decoration, quick and easy installation, short construction period, comprehensive benefits, and has a good price advantage, A wide range of uses, great potential energy efficient building envelope materials, but also the Ministry of Construction to promote and promote a new energy-saving sheet.

- Q: Rock wool sandwich board standards which

- Up and down the surface: the use of galvanized color steel plate, the thickness of 0.4-0.8mm. According to the specific requirements of customers, can also be used galvanized steel or galvanized steel plate. The steel plate is first molded by a molding machine and is compounded with the rock wool factory.

- Q: Pressure-type sandwich color plate thickness 100mm What is the socket type

- In general, this type of plug-in, such as Heilongjiang, Czech Republic, the European-style rock wool board has plug-in.

- Q: What is the difference between a steel structure installation sandwich panel and a field composite board approach?

- Color steel, also known as: color pressure tile, is the use of color coated steel plate, the cold bending into a variety of wave-type pressure plate, it applies to industrial and civil construction, warehouses, special buildings, large span steel housing Roof, wall and interior and exterior decoration, with light, high strength, rich color, convenient construction, earthquake, fire, rain, long life, free.

Send your message to us

aluminum honeycomb panels and sandwich panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 88 m²

- Supply Capability:

- 888888888 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords