Aluminum Foil Facing Laminate Film with LDPE

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Structure

Widely used for laminating with EPE insulation, Bubble insulation, woven fabric insulation, etc

● Aluminum foil – LDPE

● Aluminum foil- PET- LDPE

● Clear Transparent PET-Aluminum foil – LDPE

● Aluminum foil-Metallized PET- LDPE

● Metallized PET- LDPE

Product Application

Widely used for laminating with EPE insulation, Bubble insulation, woven fabric insulation, etc

Product Advantage

Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• Environmentally friendly, no smell and not-toxic;

• Smooth and clear surface;

Product Packing

1. Waterproof paper then PVC shrinking Film

2. Kraft paper only

3. Woven cloth

4. Kraft paper or Water Proof Film then Metal/wooden pallet

5. (Also as your request. )

Product Remarks

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

Product Data Sheet

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 33.5 | ASTM D646 |

Thickness | mic | 23.2 | ASTM D646 |

Tensile strength: M. D. X. D. | N/15mm | 13.5 13.5 | ASTM D882 |

Delaminating Values | N/15mm | 1.5 | ASTM D904 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -40°C 130°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permanence | ng/N.s | 1.15 | ASTM E-96 |

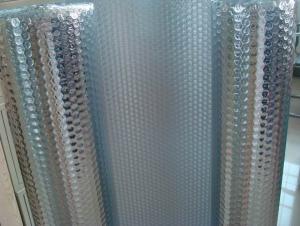

Product Picture

FAQ

1. What is the product keeping conditions?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

2. What is the guarantee years of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. What is the delivery time of the order?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Is it possible to use aluminum foil facing as a substitute for a pizza crust?

- <p>While it's not conventional, you can technically use aluminum foil facing as a makeshift pizza crust in a pinch. However, it won't provide the same texture or taste as a traditional crust. Aluminum foil is not designed for consumption and lacks the nutritional value of a real pizza crust. It's advisable to use a proper pizza dough or a store-bought crust for the best results. If you're in a bind, consider alternatives like using a tortilla or flatbread for a makeshift crust.</p>

- Q: Is it possible to reuse aluminum foil facing after cleaning it?

- <p>Yes, you can reuse aluminum foil facing after washing it, provided it is thoroughly cleaned and dried. Ensure that all residue is removed and it is completely dry to prevent bacterial growth. However, it's important to note that the foil's effectiveness as a barrier may decrease with each use, and it's generally recommended to use a fresh piece for food safety and hygiene, especially when in contact with food.</p>

- Q: Explain the differences between food wrap and aluminum foil facing in a few sentences.

- <p>Food wrap, also known as plastic wrap, is a thin, flexible plastic film used to cover and preserve food, keeping it fresh and protected from contaminants. It's typically clingy and transparent, allowing you to see the food inside. Aluminum foil facing, on the other hand, is a type of laminate that has a layer of aluminum foil bonded to a plastic film. This facing is used for various purposes, including increasing the barrier properties of the plastic, providing a shiny appearance, and enhancing the product's durability. It's often used in packaging to protect and preserve food items, but it's not as clingy or transparent as food wrap and is not meant for direct contact with food in the same way.</p>

- Q: This question asks for methods to utilize aluminum foil as a tool for preparing quick and easy meals.

- <p>Aluminum foil facing is a versatile tool for quick meal preparation. One method is the 'foil packet' technique, where you place ingredients like vegetables, protein, and seasonings in a foil pouch and bake or grill. This method helps retain moisture and flavor. Another way is to use foil as a makeshift baking tray for items like fish or potatoes, which can be seasoned and wrapped in foil for a one-step cleanup. Foil can also be used to cover food during grilling to prevent flare-ups or to steam vegetables. Always ensure food is cooked thoroughly and be cautious of potential aluminum leaching, especially with acidic foods.</p>

- Q: Is it safe to use recycled aluminum foil as a facing material in cooking?

- <p>No, it is not recommended to use recycled aluminum foil for cooking. Recycled aluminum foil may contain impurities, contaminants, or have been exposed to chemicals that could be harmful when heated. Additionally, the quality and safety of recycled materials are often not as strictly controlled as new materials, which could lead to potential health risks. It's always best to use new, high-quality aluminum foil for cooking to ensure food safety and hygiene.</p>

- Q: Is there a concern that aluminum from aluminum foil can seep into food during cooking or storage?

- <p>There is minimal risk of aluminum leaching from aluminum foil into food. Aluminum foil is generally safe for cooking and food storage when used properly. The risk increases with acidic or alkaline foods and high temperatures, but under normal cooking conditions, the amount of aluminum that could leach is negligible. However, it's best to avoid wrapping food in aluminum foil for long periods or at very high temperatures to minimize any potential exposure.</p>

- Q: Is it safe to use aluminum foil with a shiny side to wrap food for grilling?

- <p>Yes, you can use aluminum foil facing to wrap food for grilling. The shiny side of aluminum foil is non-stick and is safe for use with food. It helps prevent food from sticking to the foil and allows for even cooking. However, ensure that the foil does not come into direct contact with the heat source as it may cause the foil to tear or burn, potentially releasing aluminum particles into the food. Always follow grilling guidelines and safety precautions to avoid any risks.</p>

- Q: Explain the distinction between aluminum foil insulation with and without a vapor barrier.

- <p>Aluminum foil insulation with a vapor barrier is designed to prevent moisture from passing through, which is crucial in humid environments to prevent condensation and mold growth. The vapor barrier is a layer that acts as a moisture control, enhancing the insulation's effectiveness. On the other hand, aluminum foil without a vapor barrier does not have this moisture-resistant layer, making it less effective in controlling moisture and potentially leading to condensation issues. The presence of a vapor barrier can also impact the thermal performance and energy efficiency of the insulation.</p>

- Q: Is it safe to use aluminum foil facing inside a pressure cooker and does it pose any risks?

- <p>Using aluminum foil facing in a pressure cooker is generally safe and is commonly used to prevent food from sticking to the pot. However, it's important to ensure that the foil does not block the pressure release valve or the vent, as this could lead to a buildup of pressure and potentially cause the cooker to malfunction. Always follow the manufacturer's guidelines for your specific pressure cooker model to avoid any safety issues.</p>

- Q: Is it possible to use aluminum foil facing in the creation of desserts?

- <p>Yes, aluminum foil facing can be used for making desserts, particularly for baking purposes. It is often used to line baking sheets or molds to prevent desserts from sticking, making them easier to remove after baking. It also helps in maintaining the shape and presentation of the dessert. However, it's important to ensure that the foil does not come into direct contact with the dessert if it's not oven-safe, as this could lead to contamination or uneven cooking. Always follow the manufacturer's guidelines for the specific type of aluminum foil you are using.</p>

Send your message to us

Aluminum Foil Facing Laminate Film with LDPE

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords