Aluminum Foil Facing FSK Tapes HVAC Insulation T-S2501P

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 112 m²

- Supply Capability:

- 30000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Description:

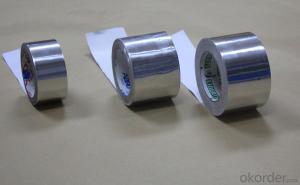

T-F3604FR Aluminum Foil Tape

Production Description

T-F3604FR Aluminum Foil Tape is a 36u nominal dead soft aluminum foil with aggressive solvent acrylic adhesive and protected by easy release liner.

Features

¨ Excellent Peel Adhesion ¨ Good Initial Tack & Permanent Bonding

¨ Good Water & Fire Resistance ¨ Outstanding Temperature & Aging Resistance

Applications

Super performance, professional grade 36u foil tape. Ideal for sealing joints / seams against moisture and vapor on foil jacketing insulation. Suitable for many other permanent sealing, holding, splicing or masking applications requiring the protection offered by a foil backing

Technical Data Sheet

Property | Unit | Value | Test Method |

Backing Thickness | Micron | 36 | PSTC-33 / ASTM D3652 |

Peel Adhesion | N/25mm | 20 | PSTC-1 / ASTM D3330 |

Tack Rolling Ball | cm | 20 | PSTC-6 / ASTM D3121 |

Tensile Strength | N/25mm | 50 | PSTC-31 / ASTM D3759 |

Elongation | % | 3.0 | PSTC-31 / ASTM D3759 |

Service Temperature | °C | -30 ~ +120 | ---------- |

Applying Temperature | °C | +10 ~ +40 | ---------- |

Cut Roll: 48mm, 50mm (2"), 60mm, 63mm (2.5"), 72mm, 75mm (3"), 96mm, 100mm (4").

Jumbo Roll: 1200mm x 1350M, 1200mm x 1200M.

Remarks:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm; Length: Cut Roll: ±0.3m, Jumbo Roll ±0.5%.

3. The product should be stored at room temperature and kept from wet and heat source.

Shelf life: One year from shipment date when stored at 21°C (70°F) / 50% relative humidity out of direct sunlight.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

- Q: Is it possible to reuse the aluminum foil that was previously used on a surface?

- <p>Reusing aluminum foil facing can be tricky. If the foil is still in good condition without any tears or punctures, and it's clean, you might be able to reuse it for a similar application. However, it's important to note that the adhesive on the back of the foil can weaken over time and with use, which may affect its ability to stick properly. Additionally, if the foil has been exposed to high heat or has been used in a way that compromises its integrity, it's safer and more effective to replace it with new foil to ensure the best performance and avoid any potential hazards.</p>

- Q: What specific cleaning procedures should be followed after using aluminum foil facing?

- <p>After using aluminum foil facing, there are a few special cleaning methods to consider. First, remove any leftover food or debris from the surface. If it's a reusable aluminum foil facing, gently wash it with warm soapy water and a soft sponge, avoiding abrasive materials that could scratch the surface. Rinse thoroughly and dry completely to prevent rust. For disposable foil, simply dispose of it according to local waste management guidelines. Avoid using harsh chemicals or extreme heat as they can damage the aluminum foil facing. Regular maintenance will ensure the longevity and hygiene of your aluminum foil facing.</p>

- Q: What are the methods to ensure food does not adhere to aluminum foil while baking?

- <p>To prevent food from sticking to aluminum foil when baking, you can use a few methods. First, lightly grease the foil with cooking spray or oil before placing food on it. Second, consider using a non-stick spray or a light brushing of butter or oil directly on the food itself. Another option is to use parchment paper as a barrier between the food and the foil. Additionally, ensure the food is not overcooked, as this can cause it to stick. Lastly, avoid using shiny, new aluminum foil for acidic or sugary foods as it may react with the foil.</p>

- Q: Is it safe and effective to use aluminum foil facing material for wrapping rice for storage purposes?

- <p>Using aluminum foil facing to wrap rice for storage is not recommended. Aluminum foil facing is not designed for food contact and may contain chemicals that could contaminate the rice. Instead, opt for food-grade materials like plastic bags or containers specifically designed for food storage. These materials are safer and help maintain the freshness and quality of the rice.</p>

- Q: What safety measures should be considered when using aluminum foil in a kitchen setting?

- <p>When using aluminum foil in the kitchen, it's important to handle it carefully to avoid cuts from sharp edges. Always use a cutting board when cutting foil to prevent damage to countertops. Avoid using aluminum foil with non-stick cookware, as it can scratch the surface. Do not use aluminum foil in broilers or ovens above 450掳F (232掳C), as it can melt and release toxic fumes. Never use aluminum foil to wrap foods that will be cooked in a microwave, as it can cause sparks and fires. Always ensure that foil is properly secured when used to cover food to prevent it from coming into contact with the heating elements of the oven.</p>

- Q: What are the most effective ways to clean surfaces that have aluminum foil applied to them?

- <p>The best cleaning methods for aluminum foil facing involve gentle cleaning to avoid damaging the foil. Use a soft cloth or sponge with warm water and mild dish soap to wipe the surface. Avoid abrasive cleaners or scrubbing, as this can scratch or tear the foil. For stubborn stains, a mixture of baking soda and water can be applied as a paste and gently rubbed with a soft cloth. Always rinse thoroughly and dry the surface to prevent water spots and maintain the integrity of the aluminum foil.</p>

- Q: Can aluminum foil be used as a facing material to construct a sandwich?

- <p>While aluminum foil is not traditionally used as a facing material for making sandwiches, it can technically be used to wrap a sandwich for storage or transportation. However, it's not suitable for direct contact with the sandwich ingredients as it can tear or leave aluminum particles on the food, which is not ideal for consumption. Instead, use bread or other edible facing materials to construct the sandwich, and aluminum foil for wrapping it if needed.</p>

- Q: Is it safe or practical to use aluminum foil as a facing material for cooking purposes?

- <p>Yes, aluminum foil facing can be used for cooking, but with caution. It's often used to line baking sheets, cover dishes for steaming, or wrap foods for roasting. However, it's not recommended for direct contact with acidic or salty foods as it can react and leach aluminum into the food. Also, avoid using it at high temperatures as it can melt and release harmful fumes. Always follow the manufacturer's guidelines for safe use.</p>

- Q: This question asks for methods to clean stubborn food residue from the aluminum foil facing of a baking sheet or similar kitchen item.

- <p>To remove stuck-on food from aluminum foil facing, first let the surface cool down. Then, use a plastic scraper or an old credit card to gently lift the residue without scratching the foil. For stubborn stains, make a paste of baking soda and water, apply it to the area, and let it sit for a few minutes before scrubbing. Alternatively, use a mixture of vinegar and water to loosen the food particles. After cleaning, rinse thoroughly and dry to prevent further food adhesion.</p>

- Q: What is the most suitable material for food packaging that ensures safety and is also eco-friendly?

- <p>The best material for food packaging that is both safe and environmentally friendly is biodegradable or compostable material. Materials such as PLA (Polylactic Acid), made from renewable resources like corn starch, and paper-based packaging are preferred. They are non-toxic, compostable, and reduce plastic waste. Additionally, materials like glass and metal can be recycled and are also considered safe for food contact. However, it's crucial to consider the entire lifecycle of the packaging to ensure it's truly sustainable.</p>

Send your message to us

Aluminum Foil Facing FSK Tapes HVAC Insulation T-S2501P

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 112 m²

- Supply Capability:

- 30000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords