Aluminum Foil Facing HVAC Insulation Tapes - T-S5006P

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m²

- Supply Capability:

- 30000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

T-S5001PFR Aluminum Foil Tape

Flame retardant aluminum foil tapes

Production Description

T-F3604FR Aluminum Foil Tape is a 50u nominal dead soft aluminum foil with aggressive solvent acrylic adhesive and protected by easy release liner.

Features

¨ Excellent Peel Adhesion ¨ Good Initial Tack & Permanent Bonding

¨ Good Water & Fire Resistance ¨ Outstanding Temperature & Aging Resistance

Applications

Super performance, professional grade 36u aluminum foil tape. Ideal for sealing joints / seams against moisture and vapor on foil jacketing insulation. Suitable for many other permanent sealing, holding, splicing or masking applications requiring the protection offered by a foil backing

Technical Data Sheet

Property | Unit | Value | Test Method |

Backing Thickness | Micron | 36 | PSTC-33 / ASTM D3652 |

Peel Adhesion | N/25mm | 20 | PSTC-1 / ASTM D3330 |

Tack Rolling Ball | cm | 20 | PSTC-6 / ASTM D3121 |

Tensile Strength | N/25mm | 50 | PSTC-31 / ASTM D3759 |

Elongation | % | 3.0 | PSTC-31 / ASTM D3759 |

Service Temperature | °C | -30 ~ +120 | ---------- |

Applying Temperature | °C | +10 ~ +40 | ---------- |

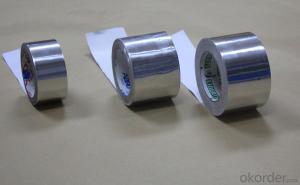

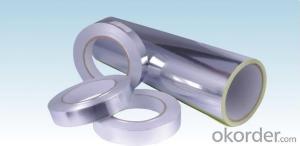

Cut Roll: 48mm, 50mm (2"), 60mm, 63mm (2.5"), 72mm, 75mm (3"), 96mm, 100mm (4").

Jumbo Roll: 1200mm x 1350M, 1200mm x 1200M.

Remarks:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm; Length: Cut Roll: ±0.3m, Jumbo Roll ±0.5%.

3. The product should be stored at room temperature and kept from wet and heat source.

Shelf life: One year from shipment date when stored at 21°C (70°F) / 50% relative humidity out of direct sunlight.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

- Q: What distinguishes various grades of aluminum foil sheets from one another?

- <p>Different grades of aluminum foil sheets are distinguished by their thickness, strength, and purity. Grade 1 is the purest and softest, used for food wrapping and baking. Grade 2 is harder and more tear-resistant, suitable for heavy-duty use like grilling. Grade 3 is an alloy and offers high strength and durability, often used in industrial applications. Grade 4 is a heat-treatable alloy, providing high strength and used in aerospace and automotive industries. Each grade has specific applications based on its unique properties.</p>

- Q: What are the advantages of using food covers made from materials other than traditional ones, specifically regarding health benefits?

- <p>Yes, there are health benefits to using food covers made from alternative materials. For instance, using food covers made from materials like beeswax or silicone can reduce the use of single-use plastic, which is beneficial for both the environment and human health by minimizing exposure to harmful chemicals that can leach from plastic. Additionally, some materials like glass or stainless steel food covers are non-porous and do not retain odors or bacteria, which can help maintain food freshness and safety. Using eco-friendly and reusable food covers can also contribute to a reduction in waste, promoting a healthier planet and, by extension, a healthier lifestyle.</p>

- Q: Can aluminum foil be shaped into a roasting rack?

- <p>Yes, you can create a makeshift roasting rack using aluminum foil. To do this, take two long sheets of aluminum foil and fold them back and forth to create a series of parallel ridges. These ridges will provide support for your roast while allowing air to circulate underneath. Place the folded foil on a baking sheet, spacing the ridges evenly apart to create a grid-like pattern. Your roast can then be placed on top of this foil 'rack' for cooking. This method is a simple and effective way to elevate your food for better heat distribution and crisping.</p>

- Q: Is it possible to use aluminum foil with a non-stick coating as a substitute for non-stick baking or grilling pans?

- <p>Yes, aluminum foil facing can be used as a non-stick surface for baking pans or grilling pans. It provides a smooth, non-stick surface that prevents food from sticking and makes cleanup easier. However, it's important to ensure that the foil is heavy-duty and not too thin to avoid tearing during use. Additionally, while it can be a temporary solution, it's not as durable as a true non-stick surface and may require frequent replacement.</p>

- Q: Explain the differences between aluminum foil facing and plastic wrap concerning their safety when used for food storage.

- <p>Aluminum foil facing and plastic wrap are both used for food storage, but they have different properties affecting food safety. Aluminum foil is a metal that provides a good barrier against air and moisture, but it doesn't contain any plasticizers that could potentially leach into food. It's also heat resistant, making it suitable for cooking and baking. On the other hand, plastic wrap is made from polymers and can be affected by heat, potentially releasing chemicals into food if overheated. It's not recommended for use in microwaves or for wrapping hot foods. Additionally, plastic wrap can cling to food, which might lead to direct contact with the plastic material, whereas aluminum foil creates a barrier without sticking to the food.</p>

- Q: What are the various materials used as facings for aluminum foil, and how do they differ from one another?

- <p>Aluminum foil facing materials are used in construction and insulation to provide a barrier against air and moisture. The different types include: 1) Kraft paper facing, which is a strong, absorbent paper used for general purposes; 2) Glassine facing, a thin, glossy paper with good water resistance; 3) PE-coated facing, where a layer of polyethylene is applied for enhanced water resistance; 4) Aluminum foil facing, which is a thin layer of aluminum for superior barrier properties; 5) Silicone-treated glass fabric, offering high-temperature resistance and used in high-performance applications. Each type has unique properties affecting their use in various applications.</p>

- Q: Is it possible to use aluminum foil with a reflective side to cook pizzas or grilled cheese sandwiches?

- <p>Yes, you can use aluminum foil facing to make pizzas or grilled cheese sandwiches. The reflective side of the foil can help distribute heat evenly, which is beneficial for cooking these items evenly. However, it's important to ensure that the foil does not come into direct contact with the heating element of your oven, as it can cause a fire hazard. Always follow safety guidelines and adjust the cooking time and temperature as needed to prevent burning or melting the foil.</p>

- Q: Is it safe to use aluminum foil that has been recycled, specifically the foil with a shiny side facing outwards?

- <p>Using recycled aluminum foil facing is generally safe, as long as it meets the standards set by regulatory bodies. Recycled aluminum foil is often used in construction materials and insulation due to its durability and insulation properties. However, it's important to ensure that the recycled foil is free from contaminants and is properly processed. For applications where the foil comes into contact with food or the skin, it's crucial to use foil that has been certified safe for such uses. Always check the manufacturer's guidelines and certifications to ensure safety.</p>

- Q: Can aluminum foil be shaped into a fish basket?

- <p>Yes, you can use aluminum foil facing to make a fish basket. Start by cutting a large piece of aluminum foil and folding it in half. Create a base by folding the edges up to form a shallow bowl shape. Then, fold the sides up and around, gradually narrowing the width to create the sides of the basket. Continue this process until you reach the desired height, ensuring the sides are sturdy enough to hold the fish. Seal the top with a final fold to complete the basket. This makeshift fish basket can be used for cooking or serving fish, but it's not recommended for heavy use or sharp objects due to the fragility of aluminum foil.</p>

- Q: This question asks for methods to clean the aluminum foil facing, which is a common household material used for cooking and food storage.

- <p>To clean aluminum foil facing, start by removing any visible debris. Use a damp cloth or sponge with mild dish soap to wipe the surface gently. Avoid abrasive materials that could scratch the foil. If there are stubborn stains, you can use a mixture of water and vinegar (1:1 ratio) to dampen the cloth. Wipe the surface and let it air dry. For baked-on food, you can use a plastic scraper or a soft nylon brush to gently remove it. Always remember to handle aluminum foil carefully to prevent tearing or damaging the surface.</p>

Send your message to us

Aluminum Foil Facing HVAC Insulation Tapes - T-S5006P

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m²

- Supply Capability:

- 30000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords