Aluminum Foil Facing Reinforced Aluminum Foil Facing FSK of CNBM in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminium Foil Facing Description:

Aluminium Foil Facing Insulation provides excellent insulation: reflects up to 97% of radiant energy in addition to resisting other types of heat transfer from conduction,convection,and radiation.The side of metalized PET/Alu forms an effective barrier against moisture,air currents and vapors.It is economical solution in many field. It is a light duty, Eco grade D/S foil Insulation. It is ideally used as sarking and insulation under roofs , in walls behind cladding or under timber floors , for residential and commercial building. Combining with glasswool or foam insulation, it is excellent as a vapor barrier for air-conditioning ducts, pipes and vessels.

2.Main Features of the Aluminium Foil Facing Insulation:

High heat reflection & low thermal conductivity

Heat preservation & energy saving

Moisture barrier & waterproof

Low flammability

Strong, durable & corrosion resistance

Light weight & easy to install

Clean, safe and fibre free & no odour and toxicity, totally environmental-friendly

No mildew growth & no rodent and insect nesting

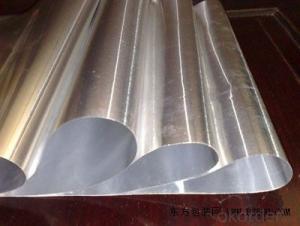

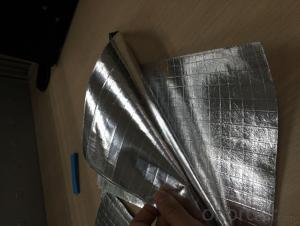

3. Aluminium Foil Facing Insulation Images

4. Aluminium Foil Facing Insulation Specification

| Model | GUOTAI710 | |

| Materail Structure | Alu.Foil/Tri-Way Scrim/PE/Natural Kraft Paper | |

| Alu.Foil Thickness | 7 micro 12micro 18micro | |

| Kraft Weight | 60 g/m² 65g/m²80g/m² 90g/m² | |

| Total Weight | 95 g/m² 100 g/m² 115 g/m² 125 g/m² | |

| Tensile Strength(MD) | 90 N/25mm | |

| Tensile Strength(CD) | 39 N/25mm | |

| Burst Strength | 120 N | |

| Reflectivity of Foil Surface | 95% | |

| Temperature Resustance | -26 ℃ to 66 ℃ not delaminating | |

| Water Vapor Permeablitity | ≤5.75 ng/N.s | |

| Roll Width | 1)1.0m,1.2m,1.25m,1.3m 2)according to the customers' request | |

Roll Length | 1)50m, 100m, 200m, 500m, 1000m 2)upon customers' request | |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe

,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

The purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Explain the distinct features of aluminum foil facing compared to other food covers.

- <p>Aluminum foil facing is a type of food cover that is made from thin sheets of aluminum, known for its high heat conductivity, moisture resistance, and ability to seal in freshness. It's often used for cooking, baking, and preserving food. Other types of food covers include plastic wraps, which are more flexible and cling to food surfaces but may not be as effective at heat conduction or preserving freshness; glass or ceramic lids, which are reusable and provide an airtight seal, but are heavier and not as convenient for single-use applications; and silicone covers, which are heat resistant and can be reused, but may not seal as tightly as aluminum foil.</p>

- Q: What is the preferred side of the lining material to face up in a baking tin: parchment paper or aluminum foil?

- <p>When lining a baking tin, it's generally better to use parchment paper with the non-shiny side facing up. Parchment paper is designed for direct contact with food and provides a non-stick surface, which is ideal for baking. Aluminum foil, on the other hand, should be dull side up to prevent food from sticking, but it's not recommended for direct contact with food as it can tear or create an uneven surface. If using foil, ensure it's food-safe and handle with care to avoid punctures.</p>

- Q: Is it possible to use aluminum foil with a reflective side for baking purposes? If yes, what is the method of using it?

- <p>Yes, aluminum foil facing can be used for baking. To use it, place the foil shiny side up on the baking sheet to reflect heat and promote even cooking. It can also be used to cover the food to prevent over-browning or to create a steaming effect, which can help in cooking delicate items. Remember to use it carefully as it can get very hot and can cause burns. Always handle with oven mitts and avoid direct contact with the foil.</p>

- Q: Is it possible to use aluminum foil with a facing layer to create a pie crust or tart crust?

- <p>Using aluminum foil facing to make a pie crust or tart crust is not recommended. Aluminum foil is not designed for baking and can react with acidic foods, potentially releasing harmful substances. Additionally, it won't provide the same texture or structure as a traditional pie crust. Instead, use materials specifically designed for baking, such as pie dough, tart shells, or parchment paper, which are safe and designed to withstand high temperatures without compromising the taste or quality of your baked goods.</p>

- Q: This question asks about potential health or safety risks associated with the use of non-stick coatings on food covers or containers.

- <p>Non-stick coatings on food covers or containers are generally safe when used as directed. However, there are some concerns. High heat can cause these coatings to release potentially harmful fumes or chemicals, such as perfluorooctanoic acid (PFOA), which has been linked to health issues. It's important to avoid overheating non-stick items and to not use them in the oven or broiler. Always follow the manufacturer's guidelines for safe use and cleaning. If the coating is scratched or peeling, it's best to replace the item to prevent ingestion of the coating particles.</p>

- Q: Explain the distinctions between aluminum foil facing and plastic wrap, including their composition, uses, and properties.

- <p>Aluminum foil facing is a thin layer of aluminum used for insulation, moisture protection, and as a barrier to light and air. It is commonly used in construction and food packaging for its heat and cold resistance. Plastic wrap, on the other hand, is made from plastic polymers like polyethylene and is primarily used for food storage, keeping food fresh by sealing in moisture and preventing contamination. Unlike aluminum foil, plastic wrap is transparent, clingy, and does not conduct heat, making it unsuitable for cooking or insulation purposes.</p>

- Q: This question asks for the most effective methods to utilize aluminum foil when preparing food for freezing or frying, specifically focusing on the aluminum foil facing.

- <p>Aluminum foil facing is best used for preparing food for freezing or frying by ensuring even heat distribution and maintaining food's moisture. For freezing, line your baking sheet with aluminum foil facing down to prevent sticking and make removal easier. When freezing individual portions, wrap them tightly in foil to protect their shape. For frying, use foil to create a barrier between the food and direct heat, which can help in even cooking. Always make sure the foil is shiny side out for better heat reflection and椋熷搧瀹夊叏. Remember to avoid overheating as aluminum foil can melt at high temperatures.</p>

- Q: This question asks whether glass or ceramic containers are preferable for storing food over plastic or metal containers.

- <p>Glass and ceramic containers are often considered better for storing food due to their non-porous nature, which prevents the absorption of flavors and potential leaching of chemicals. Glass is generally safe for storing both acidic and alkaline foods, while ceramic containers should be checked for lead-based glazes, especially for acidic foods. Plastic containers can leach chemicals over time, and metal containers may react with certain foods, affecting taste or safety. However, the choice also depends on factors like the type of food, storage duration, and personal preference.</p>

- Q: This question asks for a comparison between aluminum foil facing and other types of metal foils, highlighting their differences.

- <p>Aluminum foil facing is distinct from other metal foils due to its specific properties. It is lightweight, highly reflective, and offers excellent heat conductivity, making it ideal for insulation and cooking applications. Unlike other metal foils, aluminum foil is non-toxic and can be safely used in food packaging and preparation. It is also corrosion-resistant and has a lower melting point compared to metals like steel or copper, which affects its usability in various industries. Additionally, aluminum foil is more affordable and widely available than some other metal foils, contributing to its popularity in everyday use.</p>

- Q: This question asks for a comparison between aluminum foil facing and other types of metal foil facing, focusing on their differences.

- <p>Aluminum foil facing is distinct from other metal foil facings due to its unique properties. It is lightweight, highly reflective, and offers excellent heat resistance. It's also non-toxic and has good barrier properties against oxygen and moisture, making it ideal for food packaging and insulation. Other metal foils, such as copper or stainless steel, may have different thermal or electrical conductivity properties, and are often heavier and less flexible. Copper, for instance, has higher electrical conductivity but is less common in foil applications due to cost and weight. Stainless steel foils are more durable and corrosion-resistant but are not as reflective or lightweight as aluminum. Each type of metal foil has specific applications based on its unique characteristics.</p>

Send your message to us

Aluminum Foil Facing Reinforced Aluminum Foil Facing FSK of CNBM in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords