Heat Shield FSK Aluminum Foil Facing of CNBM in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminium Foil Facing Description:

Aluminium Foil Facing provides excellent insulation: reflects up to 97% of radiant energy in addition to resisting other types of heat transfer from conduction,convection,and radiation.The side of metalized PET/Alu forms an effective barrier against moisture,air currents and vapors.It is economical solution in many field. It is a light duty, Eco grade D/S foil Insulation. It is ideally used as sarking and insulation under roofs , in walls behind cladding or under timber floors , for residential and commercial building. Combining with glasswool or foam insulation, it is excellent as a vapor barrier for air-conditioning ducts, pipes and vessels.

2.Main Features of the Aluminium Foil Facing:

Mainly used in houses and buildings, excellent for all-season heat management at the roofs and walls, as well as dust and moisture blockage.For glasswool, rockwool and other insulation materials, heat-sealing and vapor barrier layer of veneer.

The data above are typical values only, and should not be used for specifications purpose.

Tolerance: thickness: ±10%; width: ±2mm;Length: ±0.5%

The products should be stored at room temperature, kept away from wet and heat source.

The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

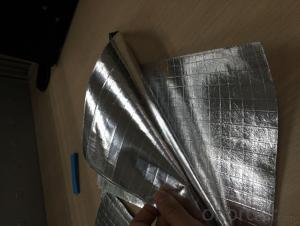

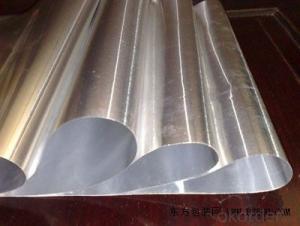

3. Aluminium Foil Facing Insulation Images

4. Aluminium Foil Facing Insulation Specification

Width(mm):1000-1300

Length(m): 200-2000

Performance | Testing Method | |

Norm | 95g/m2 | Balance |

Water vapor Permeability | 2.0ng/NS | Measured according to ASTM E96-A |

Tensile strength: | Endwise:150N/25mm Boardwise:80N/25mm | Measured according to GB/T453 |

Bursting strength | 50N | Determine according to GB/T454-2002 |

Temperature resistance | 4hours no decladding-30°C/116°C | No stratification |

Flame retardant: [away from the fire Self-extinguishing<4S] | ||

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe

,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

The purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Is it possible to use aluminum foil facing to cook a fried egg?

- <p>Yes, you can use aluminum foil facing to make a fried egg. Place a piece of aluminum foil on a flat surface and lightly grease it. Crack the egg into the center of the foil, season as desired, and fold the foil over the egg to create a sealed pouch. Heat a non-stick pan over medium heat and place the foil pouch inside. Cook for about 3-4 minutes on each side or until the egg is cooked to your liking. Be cautious when opening the foil as steam will escape. This method is a creative alternative for cooking eggs without using a traditional pan.</p>

- Q: This question asks about the potential health consequences of consuming food that has been wrapped in aluminum foil and then cooked or heated.

- <p>Eating food wrapped in aluminum foil facing is generally considered safe. Aluminum foil is designed to be food-safe and is approved by regulatory agencies like the FDA for cooking and food storage. However, there are some concerns about aluminum exposure. While the risk is minimal, it's important to note that prolonged, excessive exposure to aluminum could potentially contribute to health issues, although the link is not definitively proven. To be safe, it's recommended to avoid wrapping acidic foods like tomatoes or vinegar-based dishes in aluminum foil, as these can cause the foil to corrode and release aluminum. Additionally, using non-stick or parchment paper as an alternative can help minimize direct contact with aluminum.</p>

- Q: What are the eco-friendly alternatives to traditional plastic food wraps?

- <p>Yes, there are several environmentally friendly alternatives to traditional plastic food wraps. These include beeswax wraps, which are reusable and made from natural materials like cotton, beeswax, and jojoba oil. Another option is silicone food wraps, which are durable, reusable, and can withstand high temperatures. Additionally, there are compostable wraps made from plant-based materials like cornstarch and cellulose, which break down naturally in compost. Using reusable containers or aluminum foil can also reduce the need for single-use wraps. These alternatives help reduce plastic waste and are more sustainable for the environment.</p>

- Q: This question asks for guidance on preparing a nutritious meal using aluminum foil as a cooking method.

- <p>To make a healthy meal using aluminum foil, consider 'foil packet cooking'. Choose lean protein like chicken or fish, and pair it with a variety of colorful vegetables such as bell peppers, zucchini, and cherry tomatoes. Season with herbs, garlic, and a drizzle of olive oil. Fold the foil to create a sealed packet and bake in the oven at 400掳F (200掳C) for about 20-25 minutes or until the protein is cooked through and the vegetables are tender. This method retains nutrients and flavors while minimizing added fats.</p>

- Q: What are some alternative uses for old aluminum foil that are not commonly known?

- <p>Yes, there are several creative uses for old aluminum foil. You can use it to clean stubborn grime from pots and pans, as it can effectively scrape off burnt-on food without scratching surfaces. Aluminum foil can also be used to sharpen scissors by cutting through it multiple times. It can be fashioned into a fire starter for camping, as it retains sparks and heat well. Additionally, it can be used to create a makeshift funnel for pouring liquids or to wrap around stems of plants to protect them from frost. These are just a few of the many potential uses for old aluminum foil.</p>

- Q: Is it possible to recycle aluminum foil facing more than once?

- <p>Aluminum foil facing can be recycled, but it is typically not recycled multiple times due to the thinness and contamination issues. Recycling aluminum involves melting it down, and the thin foil can easily contaminate other aluminum products. Additionally, the foil facing is often laminated with other materials, making it difficult to separate and recycle. While some recycling facilities may accept it, the process is not as efficient as recycling other types of aluminum, and it's often advised to check with local recycling programs for their specific guidelines.</p>

- Q: What are the potential health advantages of using food packaging that does not contain aluminum?

- <p>Yes, there are health benefits associated with using aluminum-free food packaging. Aluminum has been linked to potential health risks, including Alzheimer's disease and neurological disorders. By avoiding aluminum in food packaging, there's a reduced risk of exposure to this metal, which can leach into food, especially when heated. This can help minimize the intake of aluminum, potentially lowering the risk of related health issues. Aluminum-free packaging also reduces the environmental impact and is often more sustainable, contributing to overall health by promoting a cleaner environment.</p>

- Q: Describe the optimal method for utilizing aluminum foil facing in culinary applications.

- <p>The best way to use aluminum foil facing in cooking is to preheat the oven to the desired temperature, then line the baking sheet or roasting pan with a sheet of aluminum foil, shiny side up. This helps prevent food from sticking and makes cleanup easier. When roasting meats or vegetables, you can also wrap them in foil to retain moisture and speed up cooking. Ensure the foil is not touching the heating elements to avoid fire hazards. For grilling, use foil to wrap foods like corn on the cob or to create a makeshift baking sheet for delicate items. Always be cautious with acidic foods as they can react with the aluminum.</p>

- Q: What is the most suitable material for food packaging that ensures safety and is also eco-friendly?

- <p>The best material for food packaging that is both safe and environmentally friendly is biodegradable or compostable material. Materials such as PLA (Polylactic Acid), made from renewable resources like corn starch, and paper-based packaging are preferred. They are non-toxic, compostable, and reduce plastic waste. Additionally, materials like glass and metal can be recycled and are also considered safe for food contact. However, it's crucial to consider the entire lifecycle of the packaging to ensure it's truly sustainable.</p>

- Q: Explain the differences between thin and thick aluminum foil facing in terms of thickness, durability, and usage.

- <p>Thin aluminum foil facing is characterized by its low thickness, which makes it flexible and easy to handle but less durable. It's commonly used for wrapping food, baking, and protecting surfaces. Thick aluminum foil facing, on the other hand, is more robust and tear-resistant, suitable for heavy-duty applications such as construction, insulation, and packaging. The thicker material offers better protection and durability, but it's less pliable and can be more challenging to work with.</p>

Send your message to us

Heat Shield FSK Aluminum Foil Facing of CNBM in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords