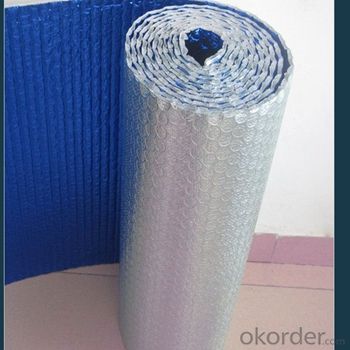

Aluminum Foil Facing LDPE Bubble Foil for Roofing Insulation Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t

- Supply Capability:

- 566755 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum foil facing insulation for Roofing Insulation

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• FSK aluminum foil facing is mainly used for duct wrap in HVAC system and other fields, such as vapor barrier etc., and suitable for off-line lamination of glass wool or rock wool. By special processing, the facing will have excellent flame retardant property.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

• Smooth and clear surface;

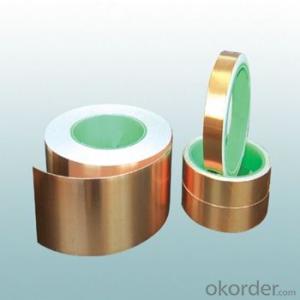

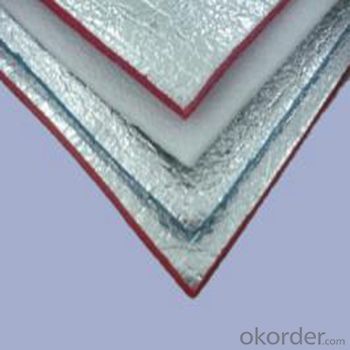

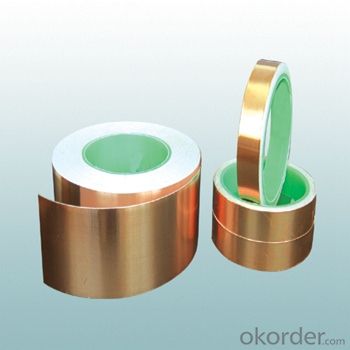

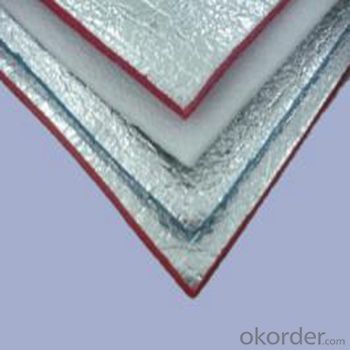

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

Basic weight | gsm | 120 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 140 75 | ASTM D828 |

Burst strength | N | 43 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C 66°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Basic weight | gsm | 120 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 140 75 | ASTM D828 |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

What is the storage condition?

1,The products should be stored at room temperature and kept from wet and heat source.

2, It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

3, The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Explain the distinct features of aluminum foil facing compared to other food covers.

- <p>Aluminum foil facing is a type of food cover that is made from thin sheets of aluminum, known for its high heat conductivity, moisture resistance, and ability to seal in freshness. It's often used for cooking, baking, and preserving food. Other types of food covers include plastic wraps, which are more flexible and cling to food surfaces but may not be as effective at heat conduction or preserving freshness; glass or ceramic lids, which are reusable and provide an airtight seal, but are heavier and not as convenient for single-use applications; and silicone covers, which are heat resistant and can be reused, but may not seal as tightly as aluminum foil.</p>

- Q: This question asks for instructions on how to clean aluminum foil facing after it has been used in cooking or baking.

- <p>To clean aluminum foil facing after use, first let it cool down to avoid burns. Then, gently scrape off any food residue with a spatula or the edge of a knife. For stubborn stains, mix a solution of warm water and dish soap, and wipe the surface with a soft cloth or sponge. Rinse with clean water and dry thoroughly. For baked-on food, you can use a plastic scraper or an old toothbrush to gently remove it. Avoid using abrasive materials that could scratch the surface. Regular cleaning will help maintain the integrity and appearance of your aluminum foil facing.</p>

- Q: What are the distinctions among various food wraps found in stores?

- <p>Yes, there are differences among food wraps available on the market. They vary in material, such as plastic, aluminum foil, parchment paper, and beeswax wraps. Each type has distinct properties: plastic cling wrap is versatile but not microwave-safe; aluminum foil conducts heat well and is reusable but can tear easily; parchment paper is ideal for baking and can withstand high temperatures; and beeswax wraps are eco-friendly, reusable, and can be used in the fridge or freezer but not for high-heat cooking. Each type also differs in terms of environmental impact, cost, and suitability for different food storage and cooking needs.</p>

- Q: This question asks for signs or methods to identify if the aluminum foil facing of a product, such as insulation or a jacket, is damaged or defective.

- <p>To determine if your aluminum foil facing is damaged or defective, look for visible signs such as tears, punctures, or holes. Check for any discoloration or rust, which could indicate corrosion. The foil should be smooth and uniform; any irregularities or bubbling might suggest a defect. Additionally, test the integrity by gently pulling or pressing the foil鈥攊f it easily tears or crumples, it may be compromised. For insulation, a damaged foil facing can lead to reduced effectiveness in heat or cold retention, so also consider the performance of the item.</p>

- Q: What are the safe and effective alternatives to aluminum foil for food packaging?

- <p>Yes, there are several substitutes for aluminum foil facing that are safe and effective for food packaging. One such alternative is parchment paper, which is non-toxic and can withstand high temperatures without releasing harmful chemicals. Silicone baking mats are also a good option, as they are reusable, non-stick, and can be used in both the oven and freezer. Additionally, beeswax wraps can be used as a natural, eco-friendly alternative for wrapping food, although they may not be suitable for high-temperature cooking. It's important to ensure that any substitute used is food-safe and can handle the intended cooking temperature to maintain food safety and quality.</p>

- Q: Is it safe to use aluminum foil with the reflective side facing inwards when dehydrating food?

- <p>Using aluminum foil facing in a dehydrator is generally safe, but it's important to ensure the foil doesn't come into direct contact with the heating element to avoid melting or fire hazards. The reflective side can help with heat distribution, but it's crucial to monitor the dehydrator closely to prevent any potential risks. Always follow the manufacturer's guidelines for use and safety precautions.</p>

- Q: Explain the distinctions between aluminum foil facing and plastic wrap, including their composition, uses, and properties.

- <p>Aluminum foil facing is a thin layer of aluminum used for insulation, moisture protection, and as a barrier to light and air. It is commonly used in construction and food packaging for its heat and cold resistance. Plastic wrap, on the other hand, is made from plastic polymers like polyethylene and is primarily used for food storage, keeping food fresh by sealing in moisture and preventing contamination. Unlike aluminum foil, plastic wrap is transparent, clingy, and does not conduct heat, making it unsuitable for cooking or insulation purposes.</p>

- Q: This question asks for a comparison of the benefits and drawbacks associated with the use of aluminum foil facing in various applications.

- <p>Aluminum foil facing offers several advantages, including excellent heat reflection, which can improve insulation and energy efficiency in buildings. It also provides a moisture barrier, which can protect against water damage and mold growth. Additionally, aluminum foil facing is lightweight, easy to install, and resistant to corrosion. However, there are disadvantages such as its limited strength and durability compared to other materials, making it prone to punctures and tears. It can also be less aesthetically pleasing and may require additional protective layers for long-term use. Furthermore, improper disposal can contribute to environmental concerns due to its non-biodegradable nature.</p>

- Q: Is it safe and effective to use aluminum foil facing for baking purposes?

- <p>Yes, you can use aluminum foil facing for baking. It's a common practice to line baking sheets with aluminum foil to prevent food from sticking and to make cleanup easier. However, ensure the foil does not come into direct contact with the heating elements of the oven as it can melt. Additionally, avoid wrapping food in aluminum foil for extended baking times at high temperatures, as it may lead to uneven cooking or potential health concerns from aluminum leaching into the food.</p>

- Q: This question asks for the optimal methods of storing food in containers not made of traditional food-safe materials.

- <p>The best ways to store food in containers made from alternative materials involve ensuring the containers are food-safe and do not impart any harmful substances to the food. For glass containers, ensure they are free of lead and are properly sealed to maintain freshness. For stainless steel containers, avoid those with non-food-grade coatings and ensure they are well-sealed to prevent spoilage. For silicone or plastic containers, look for BPA-free options and avoid high temperatures that could cause the material to leach chemicals. Always check for any odors or tastes that the container might impart to the food, and never store acidic foods in non-acid-resistant containers as this can lead to chemical reactions and contamination.</p>

Send your message to us

Aluminum Foil Facing LDPE Bubble Foil for Roofing Insulation Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t

- Supply Capability:

- 566755 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords