Polycarbonate Roofing Insulation Aluminum Foil Coated Bubble Type 13

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 cm³

- Supply Capability:

- 100000 cm³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Bubble Insulation Benefits:

Reflects 96% of radiant heat

Non-toxic / Non-carcinogenic

Does not require protective clothing or respirators to install

Durable and lightweight

Does not compress, collapse or disintegrate

Vapor and radon retarder

Easy to cut and install

Permanent and maintenance-free

Does not provide a growth medium or nutritive value for fungus, insects, or rodents

Does not support the growth of mold or mildew

Not affected by moisture or humidity

Lowers heating and cooling costs year round

Bubble Foil Application:

Metal & Steel Buildings

Homes

Roof Underlayments

Cathedral Ceilings

Crawl Spaces

Hot Water Heaters

Basement Walls

Floors

Garage Doors

Concrete slabs

Driveway snow melts

Pole barns

Post frame buildings

Poultry barns

Animal kennels

Temperature sensitive storage areas

Air Bubble Foil Insulation Tech Data:

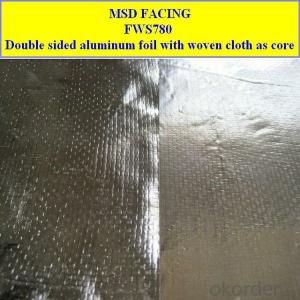

Material Structure: AL/Bubble/AL | ||

Bubble Size:D10mm*H 4mm(10*2.5/10*4/10*6/20*7/25*10)choose the bubble size | ||

Bubble Weight:0.13kg/m2 ( can be customized ) | ||

Roll Width:1.2m (lenth can be customized) | ||

PROPERTIES | TEST DATA | UNIT |

Thickness | 3.5-4 | mm |

Weight | 250 | g/m2 |

Emissivity | 0.03-0.04 | COEF |

Thermal conductivity | 0.034 | w/m0 |

Apparent Density | 85 | kg/m3 |

Reflectivity | 95-96 | % |

Water Vapour Transmission | 0.013 | g/m2kpa |

Corrosion | doesn't generate | |

Tensile Strength(MD) | 16.98 | Mpa |

Tensile Strength(TD) | 16.5 | Mpa |

- Q: do i have to have insulation in my roof?

- Maybe, you do need insulation above the ceilings (it will be between the ceiling joists/framing that also serve as the attic floor joists/framing. 1. If you have a finished attic (for a living area of some sort) then yes there should be insulation with a vapor barrier under the roof &/or between the roof framing. This will help keep heating/cooling costs down and prevent condensation from forming under the roof and doing lots of water damage over time. 2. If the attic is partially finished but used for storage only & there is attic ventilation in use also then no you don't need insulation under your roof. 3. If your attic is partially finished or completely finished but used for storage only and there is no attic ventilation then yes you should have insulation with a vapor barrier also under the roof. You don't have to have it since it's used for storage only but if you start to see condensation &/or wet areas on the wood or framing under the roof then you will need insulation with a vapor barrier installed. If for any reason insulation is installed under the roof it must be installed correctly and have in place a proper method of ventilation directly under the roof itself. All roof systems in the attic areas must have proper ventilation to prevent any possibility of condensation forming under &/or in the wood roof framing & sheathing materials that will rot the wood over time.

- Q: Help please, this home had a water pipe from meter brake in the basement as it was unoccupied/empty, the owner/builder replaced all the drywall, insulation, flooring, carpet, tile, roof, windows, hot water tank, furnace, bathroom and kitchen cabinets, new paint on all, basement ceiling was spray painted black (to hide something or to seal it?). the neighbor says the home was gutted and mold tested three times, its completely redone basically a new home inside, feedback please, it "looks" great

- the only element i will think of of, is your carpet takes up allot of the moisture that comes into your homestead, so given which you took that carpet up, your having extra of a buildup on the tile, even nevertheless the flooring would desire to not be moist, they are nonetheless taking moisture in throughout the air. Bleach will help kill the mould, not on the plant life nevertheless, they make sprays for that at any homestead progression keep. desire this allows.

- Q: Live in Houston, very hot and humid. Looking at adding radiant and additional insulation to roof in house. We have a lot of sun, and AC bills.

- we live in the desert, and got our roof coated, and instantly noticed the difference, it is much more insulated, and provides protection against leak (which was the main reason we had it done)

- Q: I am specifically considering the re-roofing of a an older home where rafters were made with 2x4 or 2x6 and the rafter space (and possibly the attic space) does not allow sufficient space for insulation and proper ventilation behind the insulation. The old layers of roofing have to be removed in any event. At this point I am considering applying insulation boards on the existing sheathing and then a new layer of sheathing before the new roofing material. (similar to a SIP: structural insulated panel) The two issues I am concerned with is that the insulation can act as a vapor barrier. Would condensation potentially rot the lower sheathing. How is this avoided in SIP roofing panels? The second issue may be with fire regulations.

- Spray in foam could be an option.. you would need to talk to someone who knows more than I do.. but Ive seen great results

- Q: the name of the company is SIG plc.I need help asap, cos I am struggling to figure it out. If it is not, what kind of competition is it???

- Sure can..........if it's the only store in town...........

- Q: should thermal insulation ever be applied directly to the underside of a roof top?

- On pole barns with metal roofing it is common to have a thin layer of insulation directly under the roofing. This prevents condensation from forming.

- Q: Without loft insulation ,the roof space is full of air.Why does this not keep the heat in?

- The warm air that collects in the attic is in close contact with the roof, heat is conducted through the roof and lost to the atmosphere.

- Q: I know when you inhale the insulation from the roof irritates the throat but what can you do to clear it from your throat after inhaling it?

- it's not your throat you should be worried about. it's your lungs. wear a respirator....or at the very least, a dust mask. you only live once so make it last.

- Q: What is the difference between roof and loft insulations?

- Potentially that the roof itself is insulated on the underside. A loft insulation could be that the base or floor of the loft/ attic is insulated. Otherwise, I'm not sure.

- Q: I would like to know which direction the one side with foil faces. The roof or the interior of the room?This is an attic room. Roof being "raw" i mean that it looks like cedar tongue in groove boards...then shingles on top of them. Which way do i face the foil side of the sheet..?thanx

- The foil side should go to the outside. I believe it's a moisture barrier.

Send your message to us

Polycarbonate Roofing Insulation Aluminum Foil Coated Bubble Type 13

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 cm³

- Supply Capability:

- 100000 cm³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords