Aluminum Flat Sheets - Extra Wide 1100/1050/1020/1060 Aluminum Coils for Decoration

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

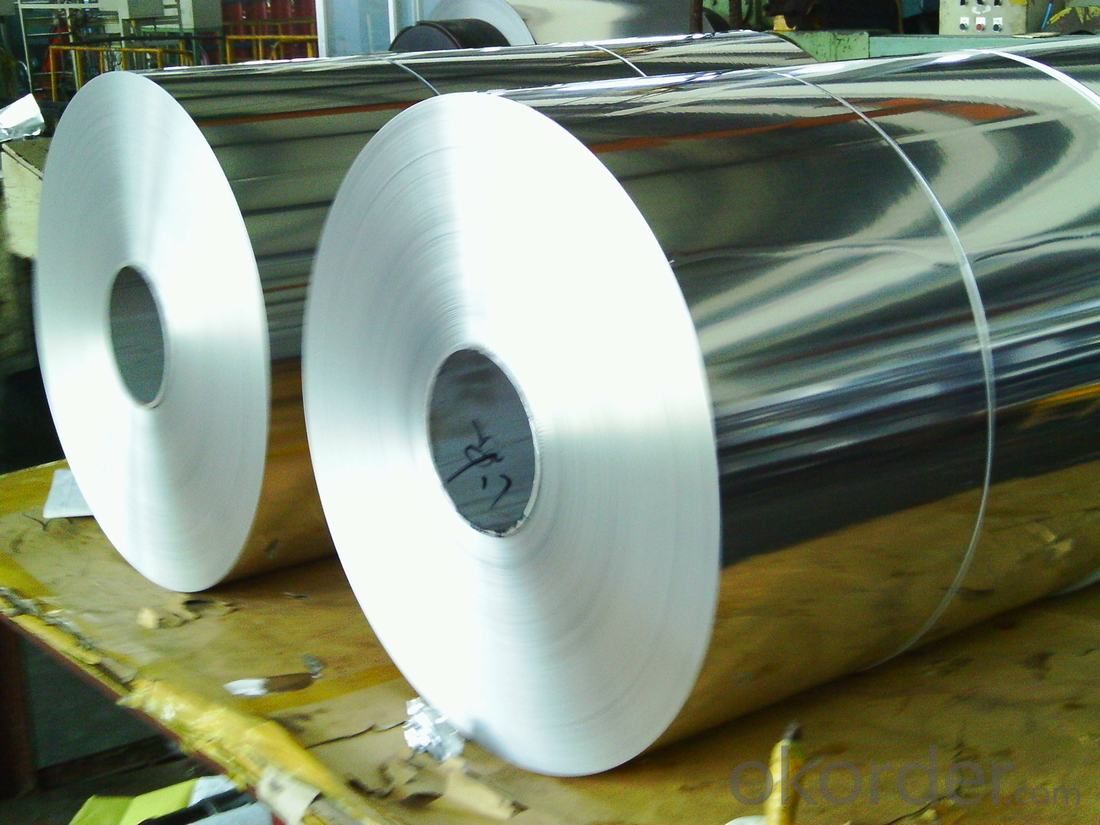

Extra Wide 1100/1050/1020/1060 Aluminum Coils for Decoration

Aluminum Description

-Hot rolling 1100/1050/1020/1060 aluminum coils for roof sheet is used for celling, decorate, ACP,Curtain Wall,Roofing Sheet, PC base, radiator,cookware,deep drawing and more.

- 1 series Aluminum Coils temper: O-H112

-1 Series Aluminum Coils Alloy: 1100/1050/1060/1200/1035/1070

-Thickness: 0.5-10mm

-Width:200-1500mm

-Length:12m Max.

Temper: h14,h16,h18,h22,h24,h26,h32,o/f

Thickness: o.o3mm-3.0mm

Width: 30mm-1700mm

Coating: pe(polyester),pvdf,epoxy

Painting thickness: standard 16-25 mic, max 40 mic

Color: according to ral colors or customer's samples

Packaging & Delivery

| Packaging Details: | Coil ID :508MM Coil Weight : about 2.5 tons or as per customers requirement Packing ; In Export Sea worhty wooden pallets Eye to wall or Eye to Sky One container can be loaded about 20 mts |

| Delivery Detail: | within 25 days after receiving L/C deposit |

- Q: I am doing a report on machining aluminum and characteristics of aluminum and can not find what the 6061 stock stands for. Looked all over library, internet, etc.

- The spec for 6061 aluminium, can be found on this link - 66.102.9.104/search?q=cache:ALU5S...

- Q: Are aluminum sheets suitable for use in food processing or storage?

- Aluminum sheets are highly suitable for use in food processing or storage. This metal is non-toxic, resistant to corrosion, and possesses exceptional thermal conductivity. These characteristics make it an ideal material for various food applications. Aluminum sheets are commonly utilized in the production of food and beverage cans, foil wraps, trays, and containers. In terms of food preservation, aluminum is impermeable to oxygen, light, moisture, and microorganisms. This quality ensures that the quality and freshness of food products are safeguarded. Additionally, it prevents the transfer of flavors, odors, and contaminants. Moreover, aluminum's lightweight and manageable nature make it convenient for packaging and transporting food items. Furthermore, aluminum sheets are hygienic and easy to clean, which is crucial in food processing and storage settings where cleanliness is of utmost importance. They can be easily sterilized and do not retain any bacteria or food particles that may lead to contamination. In conclusion, aluminum sheets are an excellent choice for food processing and storage due to their non-toxic nature, resistance to corrosion, excellent thermal conductivity, impermeability to oxygen and moisture, ability to preserve food quality, and hygienic properties.

- Q: What is the lifespan of aluminum sheets?

- Various factors, such as the aluminum's grade and thickness, the environmental conditions it encounters, and the level of maintenance it receives, can impact the lifespan of aluminum sheets. Aluminum sheets are renowned for their durability and resistance to corrosion, which contributes to their long lifespan. Aluminum possesses natural resistance against rust and corrosion, making it suitable for a wide array of applications. When given proper care and maintenance, aluminum sheets can endure for numerous years. The construction, automotive, and aerospace industries frequently utilize aluminum sheets due to their lightweight nature and robust properties. In outdoor settings, aluminum sheets can withstand harsh weather conditions, including extreme temperatures, humidity, and exposure to UV radiation. Nevertheless, continuous exposure to certain chemicals or corrosive substances can gradually cause damage. To prolong the lifespan of aluminum sheets, it is crucial to regularly clean and safeguard them. This entails eliminating any dirt or debris that might accumulate on the surface and applying protective coatings or treatments as necessary. In conclusion, while it is challenging to provide an exact timeframe for the lifespan of aluminum sheets, they are generally regarded as a long-lasting material that can withstand the test of time when adequately maintained.

- Q: This question asks for a comparison between aluminum sheets and other types of sheet metal regarding their strength and durability.

- <p>Aluminum sheets are known for their high strength-to-weight ratio, making them lighter than many other sheet metals such as steel. They offer excellent corrosion resistance, which contributes to their durability. However, in terms of sheer strength, aluminum is not as strong as steel or titanium. Steel is stronger but also heavier, and while titanium is very strong and durable, it is also more expensive and less commonly used in construction and manufacturing. Aluminum's malleability allows it to be easily shaped and formed, and it is also non-magnetic and has good thermal conductivity. Overall, aluminum is a popular choice for applications requiring a balance between strength, weight, and resistance to corrosion.</p>

- Q: What kind of paint would you like to paint on the aluminum plate?

- Paint on the aluminum plate should be painted nitrocellulose or polyester paint.Is the aluminum plate with a thickness of more than 0.2mm to 500mm, 200mm width, length less than 16m aluminum material called aluminum plate or aluminum sheet, aluminum is below 0.2mm, 200mm within the width of the row material or bar (of course, with the progress of the large equipment, the width can be 600mm row material also more). Aluminum sheet refers to the rectangular plate made of aluminium ingot rolled and divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, middle thick aluminum plate and pattern aluminum plate.Nitrocellulose lacquer is a common paint for woodwork and decoration. The main film forming material is mainly to nitrocellulose lacquer, with alkyd resin, rosin modified resin, acrylic resin, amino resin and other resin composed of hard and soft.Polyester paint, also called unsaturated polyester paint, is a kind of multi component paint, it is a kind of thick paint made of polyester resin as the main film forming material. Polyester paint film fullness, thick hard surface. Polyester paint also has varnish varieties, called polyester varnish. Polyester paint needs to be solidified during construction, and the proportion of these curing agents takes up 1/3 of the total paint. These curing agents, also known as curing agents, are mainly composed of TDI (toluene diisocyanate, /toluenediisocyanate). These free TDI will turn yellow, not only to make furniture paint yellow, but also will make the adjacent wall yellow, this is a major shortcoming of polyester paint.

- Q: what's the temperature tolerance of aluminum sheets?

- aluminum is a kind of silver white metal,melting point:660.4℃, boiling point: 2467℃,density: 2.70 g/cm?,very light, about 1/4 of iron's density.it has low hardness and good ductility, which makes it suitable for being pulled into threadlets or pressed into aluminum foils, and the later is usually used for packaging candy and cigarette. it has good electrical and temperature conductivity. it's used for the manufacture of electric wire and cable in electric power industry, and for the manufacture of cooker in daily life bined with the magnesium , copper,zinc,tin,manganese,chromium,zirconium,silicon and other elments,it can formulate various alloys that is broadly used for the manufacture of airplane,car,ship, materials of daily living equipment and the doors and windows of construction industry.aluminum is one of the best reflectors of heat and light, so it is used as thermal insulation material and the manufacture of reflecting mirror in the reflecting telescope.

- Q: Are the aluminum sheets available in different finishes (e.g., brushed, polished)?

- Yes, aluminum sheets are available in different finishes such as brushed and polished.

- Q: What are the different bending methods for aluminum sheets?

- Aluminum sheets can be bent using different methods, each with its own advantages and limitations. Various bending techniques for aluminum sheets include: 1. Air Bending: By utilizing a punch and die, a bend is formed in the aluminum sheet without direct contact. Compressed air is employed to exert force on the sheet, resulting in the desired bend. Air bending is a versatile method that allows for a range of bend angles and radii. 2. Bottom Bending: This method involves clamping the aluminum sheet between a V-shaped die and a flat die. A punch is then used to press the sheet into the V-shaped die, creating the desired bend. Bottom bending is suitable for achieving sharp bends with small radii. 3. Coining: Precise and crisp bends are formed by applying high pressure to the aluminum sheet between a punch and a die. Coined bends exhibit minimal springback. However, this method requires specialized equipment and is typically utilized for high-volume production. 4. Roll Bending: By passing the aluminum sheet between a set of rollers, it is gradually bent into the desired shape. Roll bending is commonly employed for creating cylindrical or conical shapes. This technique can achieve large radii and is suitable for thicker aluminum sheets. 5. Press Brake Bending: This commonly used method employs a hydraulic or mechanical press brake to create bends in aluminum sheets. The sheet is clamped between a punch and a die, and the press brake applies force to create the bend. Press brake bending offers flexibility in terms of bend angles and radii. It is important to consider various factors such as the desired bend angle, radius, material thickness, and specific application requirements when selecting a bending method.

- Q: Does aluminum resist fire or is it not susceptible to catching fire?

- <p>Aluminum sheets are not fireproof but have a high resistance to fire. They do not burn or support combustion like wood or paper. Aluminum has a melting point of around 660掳C (1220掳F), and it forms a protective oxide layer when heated, which prevents further oxidation and slows down the heating process. While it can get hot and deform under extreme heat, it won't catch fire or contribute to a fire's spread. However, it's important to note that aluminum can still conduct heat, so it's not completely immune to the effects of fire.</p>

- Q: is putting Aluminium foil behind the wind shield actually generate more heat and make the car hotter inside or make the car inside cooler? assume you put foil behind all windows.

- reflects heat outwards

Send your message to us

Aluminum Flat Sheets - Extra Wide 1100/1050/1020/1060 Aluminum Coils for Decoration

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords