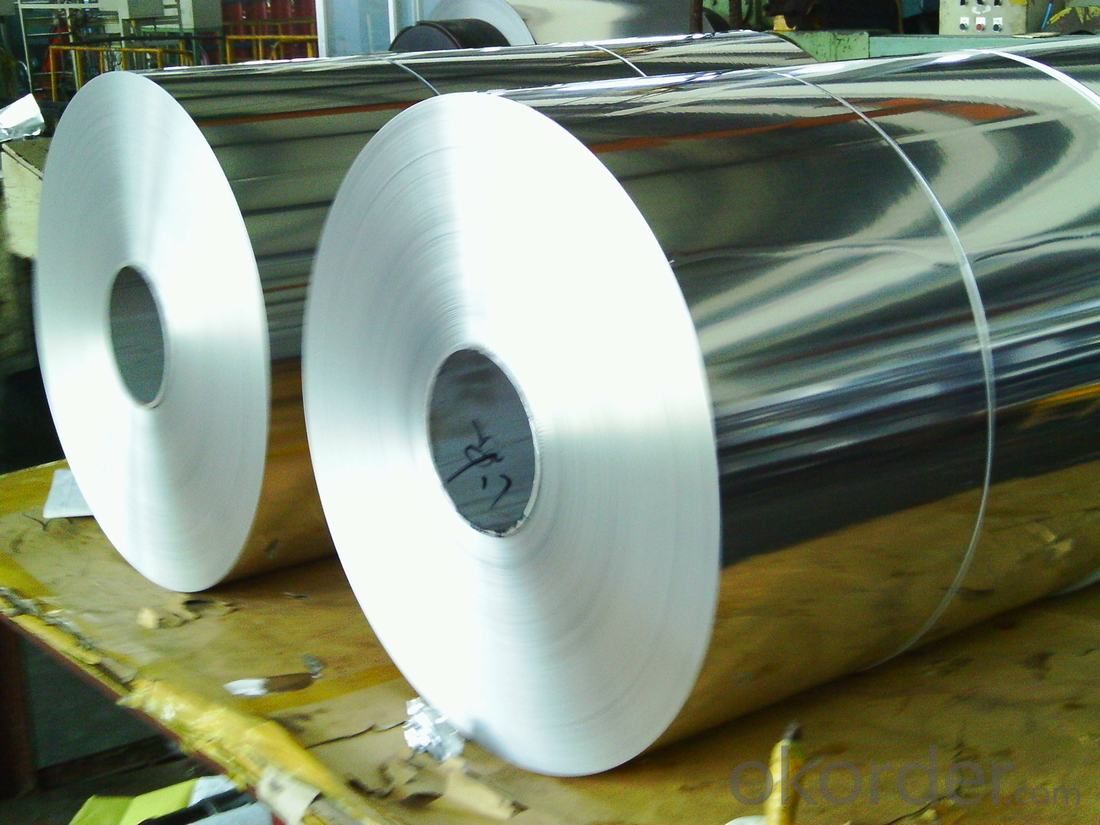

Aluminum Sheets Eau Claire - Bright Surface 1100/1050/1020/1060 Aluminum Coils for Lamination

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminum Description

-Hot rolling 1100/1050/1020/1060 aluminum coils for roof sheet is used for celling, decorate, ACP,Curtain Wall,Roofing Sheet, PC base, radiator,cookware,deep drawing and more.

- 1 series Aluminum Coils temper: O-H112

-1 Series Aluminum Coils Alloy: 1100/1050/1060/1200/1035/1070

-Thickness: 0.5-10mm

-Width:200-1500mm

-Length:12m Max.

Temper: h14,h16,h18,h22,h24,h26,h32,o/f

Thickness: o.o3mm-3.0mm

Width: 30mm-1700mm

Coating: pe(polyester),pvdf,epoxy

Painting thickness: standard 16-25 mic, max 40 mic

Color: according to ral colors or customer's samples

Packaging & Delivery

| Packaging Details: | Coil ID :508MM Coil Weight : about 2.5 tons or as per customers requirement Packing ; In Export Sea worhty wooden pallets Eye to wall or Eye to Sky One container can be loaded about 20 mts |

| Delivery Detail: | within 25 days after receiving L/C deposit |

Aluminium (or aluminum; see spelling differences) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, nonmagnetic, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal in the Earth's crust. It makes up about 8% by weight of the Earth's solid surface.

Aluminium metal is so chemically reactive that native specimens are rare and limited to extreme reducing environments. Instead, it is found combined in over 270 different minerals.The chief ore of aluminium is bauxite.

Aluminium is remarkable for the metal's low density and for its ability to resist corrosion due to the phenomenon of passivation. Structural components made from aluminium and its alloys are vital to the aerospace industry and are important in other areas of transportation and structural materials. The most useful compounds of aluminium, at least on a weight basis, are the oxides and sulfates.

FAQ

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe

,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can someone please help me with the resonance structure for AlCl3. When I draw it, the central Al does not have a complete octet. I read that this is usually the case for atoms like Boron and Aluminium who only have three valence electrons. Is this correct? Also, as a follow on question, does AlCl3 display resonance?

- Since aluminum only has 3 valence electrons it will be missing two electrons from its octet. This means that one of the chloride groups must share an extra electron group with the aluminum. Any three of the chlorides can share an extra electron pair with it (i.e. they'll have 2 lines attached to aluminum), so there is resonance. There are 3 to be specific, one for each chloride sharing another electron pair with Al.

- Q: the amp setting when welding aluminum tig? and what color should the electrode feeder be bronze or chrome grey? u know the one u use with your hands

- Best electrodes to use for Aluminum welding is 1.5% lanthanum oxide (gold color code.). 2% zirconia (brown) or 2% thorium oxide (red) can also be used. Note that zirconia-doped electrodes should never be used for DC welding. A lot of welders like to quote offhand the rule 1 amp for every 0.001 inch of thickness. This applies to steel, stainless, and nickel alloys only. Due to the lower melting point, lower specific heat capacity, and higher thermal conductivity of of Al, this rule should NOT be used for Al! I recommend welding a test piece first with the same joint configuration and thickness of the part you intend to weld. Note that fillet welds require more current than butt welds or edge welds. Start out by using 2/3 amp per 0.001 of thickness, in other words, reduce the current of the above rule by about 30-40% . Make 3 test weld, then check to see if there's any visible penetration on the other side. If you don't see any through-pentration at all, increase the current by about 10-20 amps and test again.

- Q: How do aluminum sheets perform in terms of sound insulation?

- Aluminum sheets are not well-known for their sound insulation properties. Due to their relatively low density and thinness, aluminum sheets do not provide substantial soundproofing capabilities. They are more commonly used in applications where their lightweight nature, corrosion resistance, and thermal conductivity are desired, rather than for their sound insulation properties. For effective sound insulation, other materials such as rubber, foam, or fiberglass are often preferred.

- Q: Is it possible to construct furniture using aluminum sheets?

- <p>Yes, you can use aluminum sheets to make furniture. Aluminum is a lightweight, durable, and corrosion-resistant material that is often used in modern furniture design. It can be easily shaped and welded, making it suitable for a variety of furniture pieces such as tables, chairs, and shelving. However, it's important to consider the design and structural integrity, as well as the finish and comfort, when creating furniture with aluminum. It's also advisable to use appropriate tools and techniques to ensure safety and quality in the construction process.</p>

- Q: Are 101 aluminum sheets suitable for conductive heat transfer applications?

- No, 101 aluminum sheets are not suitable for conductive heat transfer applications. 101 aluminum is a commercially pure aluminum alloy that has low electrical conductivity. It is not able to efficiently conduct heat, making it unsuitable for applications where heat transfer is desired. For conductive heat transfer applications, it is better to use alloys that have higher thermal conductivity, such as 6061 or 7075 aluminum. These alloys have better heat transfer properties and are commonly used in heat sinks, heat exchangers, and other applications where efficient heat transfer is required.

- Q: This question asks about the structural integrity and suitability of aluminum sheets for use in the construction of high-rise buildings.

- <p>Aluminum sheets are not typically used as the primary structural material in high-rise buildings due to their lower strength compared to steel and concrete. However, aluminum is known for its high strength-to-weight ratio, making it suitable for non-structural applications such as facades, window frames, and roofing. In high-rise construction, aluminum can be used in combination with other materials to provide a lightweight and aesthetically pleasing exterior while maintaining structural integrity with stronger materials like steel and concrete.</p>

- Q: How does the thermal conductivity of aluminum compare to other metals?

- The thermal conductivity of aluminum is relatively high compared to many other metals. It is often considered one of the best conductors of heat among common metals. Aluminum has a thermal conductivity of about 205 watts per meter kelvin (W/m·K), which is higher than copper (about 401 W/m·K) and even silver (about 429 W/m·K). This means that aluminum can transfer heat more efficiently than most other metals, making it a popular choice for heat sinks, radiators, and other applications that require effective heat dissipation. However, it is worth noting that some metals, such as diamond and graphene, have even higher thermal conductivity than aluminum.

- Q: How does the thickness of aluminum sheet affect its strength?

- The strength of an aluminum sheet is directly influenced by its thickness. Generally, a thicker aluminum sheet will possess greater strength compared to a thinner one. This correlation arises from the fact that the thickness of the sheet determines the quantity of material present, ultimately impacting its ability to endure external forces or loads. Typically, the strength of a material is measured based on its capacity to withstand stress without deforming or failing. Thicker aluminum sheets have a larger volume of material, resulting in an increased number of atoms and bonds to counteract forces. Consequently, these sheets exhibit a heightened resistance to deformation or failure, thus rendering them stronger. Furthermore, thicker aluminum sheets boast a higher load-bearing capacity. Consequently, they can endure heavier loads or higher pressures without distorting or failing. The augmented thickness allows for a greater distribution of the load, thereby reducing the stress placed on individual atoms and bonds within the sheet. Nevertheless, it is crucial to acknowledge that there exists a limit to the thickness at which the strength of an aluminum sheet reaches a plateau. Once this threshold is surpassed, further increasing the thickness may not yield significant improvements in strength. This limitation arises from the influence of other material properties of aluminum, such as its crystal structure and grain boundaries, which also contribute to determining its strength. To conclude, the strength of an aluminum sheet is directly linked to its thickness. Thicker sheets possess more material, enabling them to effectively resist deformation or failure under stress. Furthermore, their increased thickness allows them to support heavier loads or endure higher pressures. However, it is important to recognize that there is a limit to the thickness at which the strength plateaus, as other material properties also come into play.

- Q: Can aluminum sheets be an alternative to glass in certain applications?

- Yes, aluminum sheets can be an alternative to glass in certain applications. Aluminum sheets offer several advantages over glass, making them a suitable choice in specific scenarios. Firstly, aluminum sheets are lightweight and durable, making them ideal for applications where weight is a concern, such as in aerospace or automotive industries. Glass, on the other hand, is relatively heavy and brittle, which can limit its use in certain environments. Additionally, aluminum sheets have excellent corrosion resistance, making them suitable for applications in marine or coastal environments where glass may deteriorate over time due to exposure to saltwater. Aluminum sheets also have a high strength-to-weight ratio, allowing for greater design flexibility and structural integrity compared to glass. Moreover, aluminum sheets can provide better thermal insulation properties compared to glass. They offer improved heat transfer resistance, which can be advantageous in applications where temperature control is crucial, such as in the construction industry. Furthermore, aluminum sheets can be more cost-effective than glass in certain applications. The production and installation costs of aluminum sheets are often lower compared to glass, making them a more economical choice for large-scale projects. However, it is important to note that glass still has its own unique properties and advantages that make it the preferred choice in many applications, such as its transparency and optical clarity. Glass also offers better resistance to scratches and chemical corrosion compared to aluminum sheets. In conclusion, while aluminum sheets can be a viable alternative to glass in certain applications due to their lightweight, durability, corrosion resistance, thermal insulation properties, and cost-effectiveness, the choice between the two materials ultimately depends on the specific requirements and constraints of the application in question.

- Q: Are aluminum sheets suitable for solar panel applications?

- Yes, aluminum sheets are suitable for solar panel applications. Aluminum is lightweight, durable, and has excellent thermal conductivity, making it an ideal material for solar panel frames and backsheets. It is also corrosion-resistant, cost-effective, and widely available, making it a popular choice in the solar industry.

Send your message to us

Aluminum Sheets Eau Claire - Bright Surface 1100/1050/1020/1060 Aluminum Coils for Lamination

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords