Aluminum Flashing Sheets - Aluminium Chequer Plate 5052 for Boat Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminium Chequer Plate 5052 for Boat Panel

Alloy Number | AA1XXX,AA3XXX,AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Aluminium Chequer Plate 5052 for Boat Panel

Transfporation, vehicle, antiskid plate,toolbox,canopy body,

3. Feature of Aluminium Chequer Plate 5052 for Boat Panel

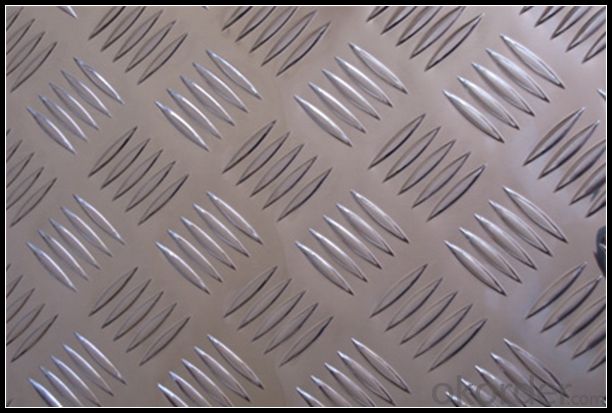

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

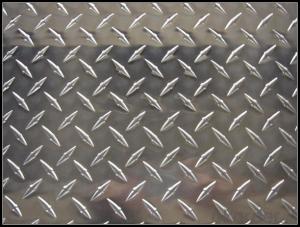

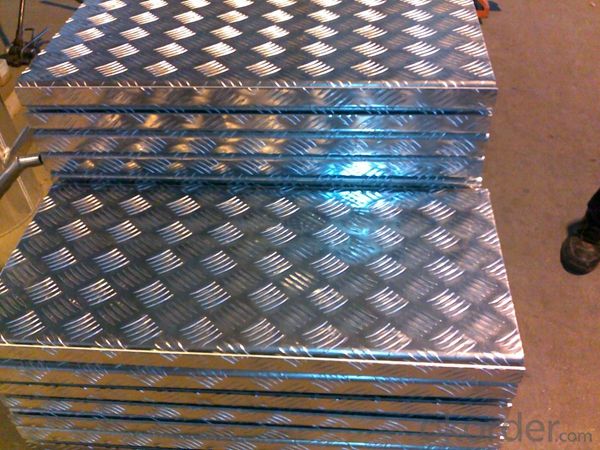

5. Image of Aluminium Chequer Plate 5052 for Boat Panel

6. Package and shipping of Aluminium Chequer Plate 5052 for Boat Panel

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What keeps things colder- plastic wrap or aluminum foil?

- Aluminum foil. It is thicker, and metal retains heat/cold longer than the thin film of plastic would. I actually use both when I freeze things like lasagna...I use a layer of plastic wrap on it first, then a layer of foil over the top. It creates an extra (albeit fine) layer of insulation.

- Q: What safety measures should be taken into account when installing aluminum sheets?

- <p>When installing aluminum sheets, it's important to follow safety precautions. Always wear appropriate personal protective equipment, including gloves and safety glasses. Ensure the work area is clear of debris and other hazards. Use the correct tools for cutting and handling aluminum sheets to prevent injuries. Be cautious of sharp edges and corners that can cause cuts. Ensure the aluminum sheets are properly secured to avoid them falling and causing harm. Follow all manufacturer guidelines for installation to ensure the stability and longevity of the aluminum sheets.</p>

- Q: Can aluminum sheets be bent or formed without cracking or breaking?

- Indeed, it is possible to bend or form aluminum sheets without causing cracks or breaks; however, this outcome is contingent upon the thickness of the sheet as well as the bending or forming technique employed. Aluminum, being an exceptionally pliable material, can be easily manipulated into various shapes without fracturing. Nevertheless, if the sheet is excessively thin or if the bending or forming procedure lacks carefulness and precision, there is a possibility of cracks or breaks occurring. To mitigate this risk, it is imperative to utilize appropriate tools and methods, such as a bending brake or a rolling machine, and to ensure that the sheet is not subjected to excessive force or stress during the process. Furthermore, annealing the aluminum sheet prior to bending or forming can enhance its flexibility and diminish the likelihood of cracking. Ultimately, with the correct approach and necessary precautions, it is feasible to successfully bend or form aluminum sheets without encountering cracks or breaks.

- Q: This question asks about the influence of aluminum sheets on the thermal insulation properties of a building.

- <p>Aluminum sheets, due to their high thermal conductivity, can actually reduce the insulation of a building if not properly used. They can conduct heat quickly, which means that they may transfer heat from the outside to the inside or vice versa, depending on the temperature difference. This can lead to increased energy consumption for heating or cooling. However, when used as a reflective barrier in combination with proper insulation materials, aluminum sheets can help reflect heat and improve insulation by reducing heat transfer. It's crucial to use aluminum sheets correctly and in conjunction with other insulating materials to achieve optimal thermal performance in buildings.</p>

- Q: Can aluminum sheets be used for pharmaceutical lab equipment?

- Aluminum sheets have the capability to be utilized in pharmaceutical lab equipment. Aluminum, a versatile material, offers numerous benefits for pharmaceutical applications. Its lightweight nature, resistance to corrosion, and exceptional thermal conductivity make it an excellent option for constructing trays, shelves, and cabinets that are employed for storing and transporting pharmaceutical substances. Moreover, aluminum can be easily sterilized and cleaned, which is vital for maintaining hygienic conditions in pharmaceutical laboratories. Nevertheless, it is crucial to acknowledge that specific pharmaceutical procedures may demand materials that comply with particular regulatory standards. Thus, it is always wise to seek advice from industry experts or regulatory bodies to ensure that the selected aluminum sheets fulfill the necessary requirements for their intended usage in pharmaceutical lab equipment.

- Q: How to clean the engine oil and kerosene on the surface of aluminum sheet?

- You can clean it with detergent of carburetor, and buy it in auto accessories shop.

- Q: How does the surface roughness of aluminum sheet affect its performance?

- The surface roughness of an aluminum sheet can significantly affect its overall performance. The roughness of the surface refers to the irregularities, bumps, and texture present on the sheet's surface. These irregularities can be measured using various methods, such as Ra (arithmetical average roughness) or Rz (mean roughness depth). One significant impact of surface roughness on aluminum sheet performance is in its ability to bond or adhere to other materials. A smoother surface allows for better adhesion, whether it is through welding, gluing, or painting. When the surface is rough, it creates less contact area and reduces the strength of the bond. This is particularly crucial in applications where the aluminum sheet is used as a structural component or in manufacturing processes that require strong adhesion. Surface roughness also affects the sheet's ability to reflect light. A smoother surface reflects light more uniformly, resulting in a higher level of reflectivity. In contrast, a rough surface scatters light in multiple directions, reducing its overall reflectivity. This property is relevant in applications such as architectural cladding, where the desired aesthetic appearance may rely on the sheet's ability to reflect light consistently. Moreover, the surface roughness of aluminum sheets can impact their corrosion resistance. A smoother surface is less prone to corrosion as it provides fewer sites for corrosion initiation. On the other hand, a rougher surface may have micro crevices or grooves that can trap moisture, salts, or other corrosive substances, accelerating the corrosion process. In applications where corrosion resistance is critical, such as marine environments or outdoor structures, maintaining a smooth surface is essential. Lastly, surface roughness affects the sheet's mechanical properties. A rough surface can act as stress concentrators, leading to increased susceptibility to fatigue, cracks, or other mechanical failures. Smoother surfaces distribute stress more evenly, enhancing the sheet's overall strength and resistance to deformation. In conclusion, the surface roughness of an aluminum sheet plays a vital role in its performance. It impacts adhesion, reflectivity, corrosion resistance, and mechanical properties. Therefore, considering and controlling the surface roughness is essential in various applications to ensure optimal performance and longevity of aluminum sheets.

- Q: This question asks for a list of various types of fasteners that can be used to secure aluminum windows to their frames.

- <p>There are several types of fasteners used for attaching aluminum windows to frames, including: 1. Screws: Commonly used for their secure hold and ease of installation. 2. Nails: Quick to use but may not provide the same level of security as screws. 3. Adhesives: Can be used for a more permanent bond, especially in certain applications. 4. Clips and brackets: Used for a more visible, decorative attachment. 5. Rivets: Provide a strong, permanent connection but are not easily removable. 6. Dowels and pins: Used for a more traditional or decorative join. 7. Structural glazing systems: Employ silicone or other sealants to bond the window to the frame. Each type of fastener has its own advantages and is chosen based on the specific requirements of the project, such as load-bearing needs, aesthetic considerations, and the desired level of permanence.</p>

- Q: Are aluminum sheets suitable for architectural roofing?

- Yes, aluminum sheets are suitable for architectural roofing. Aluminum is a lightweight material that is resistant to corrosion, making it an ideal choice for roofing applications. It is also highly durable and can withstand harsh weather conditions, including extreme temperatures, UV radiation, and strong winds. Additionally, aluminum sheets are available in a variety of colors and finishes, allowing for flexibility in design and aesthetics. Moreover, aluminum is a sustainable and environmentally friendly material as it can be recycled indefinitely without losing its properties. Overall, aluminum sheets provide excellent performance and versatility, making them a popular choice for architectural roofing.

- Q: have been taking an over the counter Antacid consistently for the past 8 years as a daily source of extra calcium per the bottle. Now, I am getting many nerve problems, similar to Lou Gehrig's disease. I am a healthy 38 year old male who excersises, eats right and is generally health conscious. I am concerned that unknowingly I have toxified my body with the aluminum that apparently is in Antacid. I did not know this until now or of course I would not have gone any where near it.Can taking Antacid lead to nerve problems such as Lou Gehrig's disease?

- Aluminum okorder /

Send your message to us

Aluminum Flashing Sheets - Aluminium Chequer Plate 5052 for Boat Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords